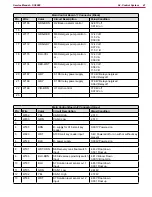

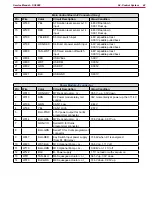

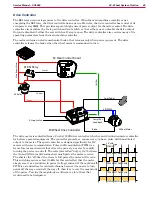

54

20 - Wheel System, Traction

Removal and Installation

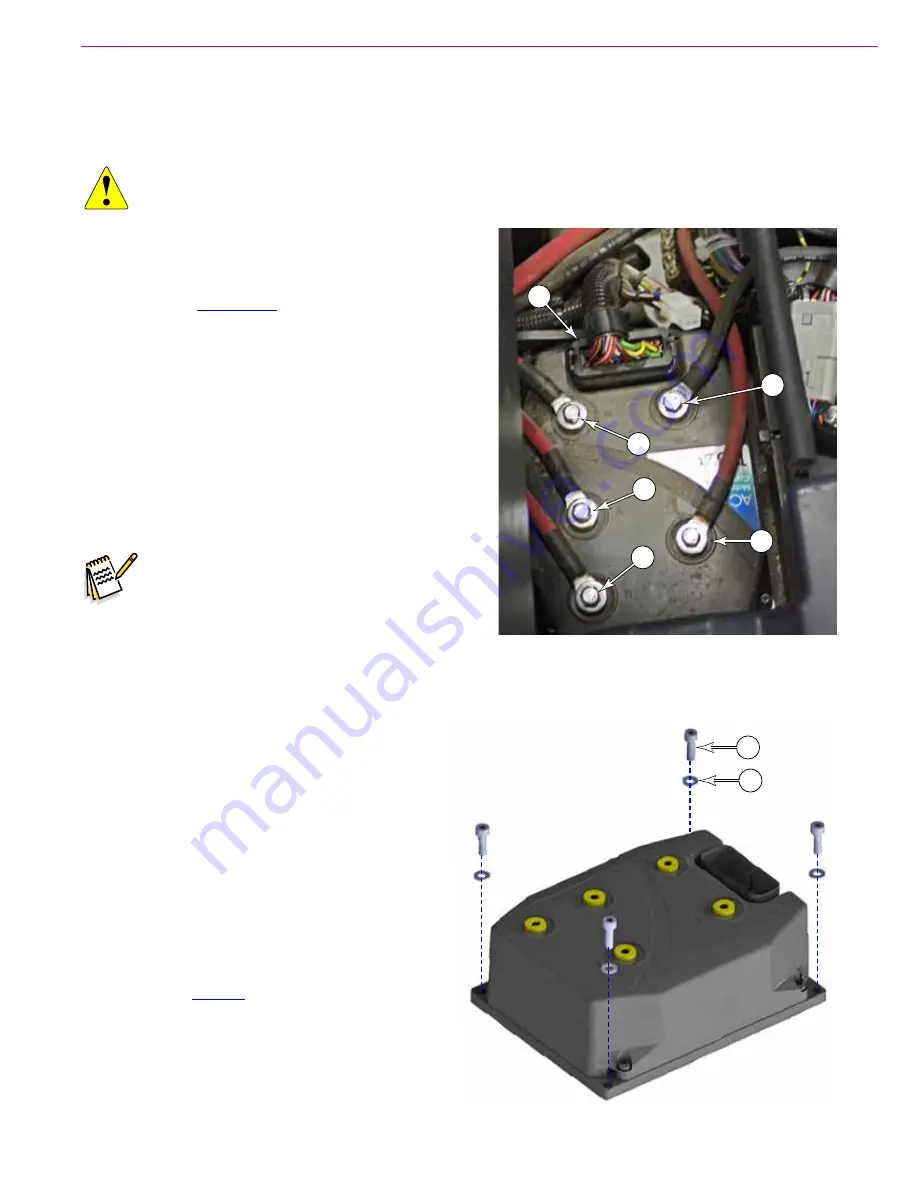

Drive Controller

WARNING:

Components below the floor cover contain high energy battery power. Disconnect the

battery connector before servicing machine.

1 Turn off the machine and disconnect the main battery

connector

2 Remove the

3 Disconnect the logic cable connector

(A)

from the drive

controller

4 Remove the M6 screw that secures the K3 relay

battery power wire

(F)

, and remove the wire, flat

washer, and lock washer

5 Remove the battery negative power wire

(E)

6 Label the 3 motor phase wires

(B,C,D)

with U, V, W,

and then remove them from the controller (with flat

washer and lock washer)

Note:

If any of the wires are reversed during

replacement, the drive motor will rotate

backward and operate loudly as the motor

windings conflict with one another. The

drive controller will also likely issue an

encoder fault because the encoder will

provide unexpected results.

7 Remove the 4 screws

(G)

and washers

(H)

from

the outer corners of the module (not the 4 inner

screws) that secure the module to the machine

frame, and remove the module

Replacement Notes

•

When replacing the wire lugs, torque the screws

to 90 lb

•

in (10 N

•

m). Don’t forget the flat and lock

washers

•

It may not be necessary to complete the drive

pedal calibration, but it is a good idea to at least

check the voltage of the neutral position as

described on

•

After replacement, test the machine drive

functions in an open area to ensure proper

operation

F

E

A

B

C

D

G

H