1

Introduction

This manual is intended for use by technicians responsible for installing and servicing LoadRunner Series Onboard

Weighing Systems.

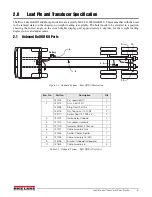

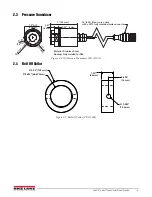

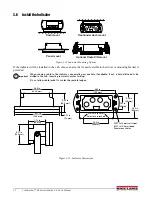

This manual contains instructions for installing various types of Onboard Weighing Systems (non Legal-for-Trade

systems). For straight trucks, this manual includes rigid under-body mounting instructions in four and six point

configurations, as well as under-body load pin installation instructions for tipping bodies and hoist chassis. Tipping

body installations can be either Lift-to-Weigh or Live-Weigh system types.

Authorized distributors and their employees can view or download this manual from the Rice Lake

Weighing Systems distributor site at

www.ricelake.com

.

Safety

Safety Symbol Definitions:

Important

CAUTION

WARNING

DANGER

Indicates an imminently hazardous situation that, if not avoided, will result in death or serious injury.

Indicates a potentially hazardous situation that, if not avoided, could result in serious injury or death, and

includes hazards that are exposed when guards are removed.

Indicates a potentially hazardous situation that, if not avoided, may result in minor or moderate injury.

Indicates information about procedures that, if not observed, could result in damage to equipment or

corruption to and loss of data.

General Safety

WARNING

Do not operate or work on this equipment unless you have read and understand the instructions and

warnings in this manual. Failure to follow the instructions or heed the warnings could result in injury or

death. Contact any Rice Lake Weighing Systems dealer for replacement manuals.

Proper care is your responsibility.

Failure to heed may result in serious injury or death.

DO NOT allow minors (children) or inexperienced persons to operate this unit.

DO NOT operate without all shields and guards in place.

DO NOT jump on the scale.

DO NOT use for purposes other than weight taking.

DO NOT place fingers into slots or possible pinch points.

DO NOT use any load bearing component that is worn beyond 5% of the original dimension.

DO NOT use this product if any of the components are cracked.

DO NOT exceed the rated load limit of the unit.

DO NOT make alterations or modifications to the unit.

DO NOT remove or obscure warning labels.

Keep hands, feet and loose clothing away from moving parts.

Содержание LoadRunner Series

Страница 2: ...LoadRunner Series OnBoard Weighing System for Roll Off Trucks Installation Service Manual 160913...

Страница 3: ......

Страница 29: ...24 LoadRunner Series Installation Service Manual...

Страница 30: ......