Maintenance

214815

37

Tighten all the screws on the loader and all fasteners, except

in the cases where the tightening torque is specified in the

assembly instructions.

The torques apply to clean, dry threads. Lubricated threads

can lead to the joint being tightened too strongly. Damaged

or dirty threads can cause torque values to be too low.

A torque amplifier may be needed when tightening screws

to high torque values.

Tightening torques should be checked immediately after

installation, and several times after a short period of use.

Incorrect tightening can damage the structure of the loader

and/or tractor.

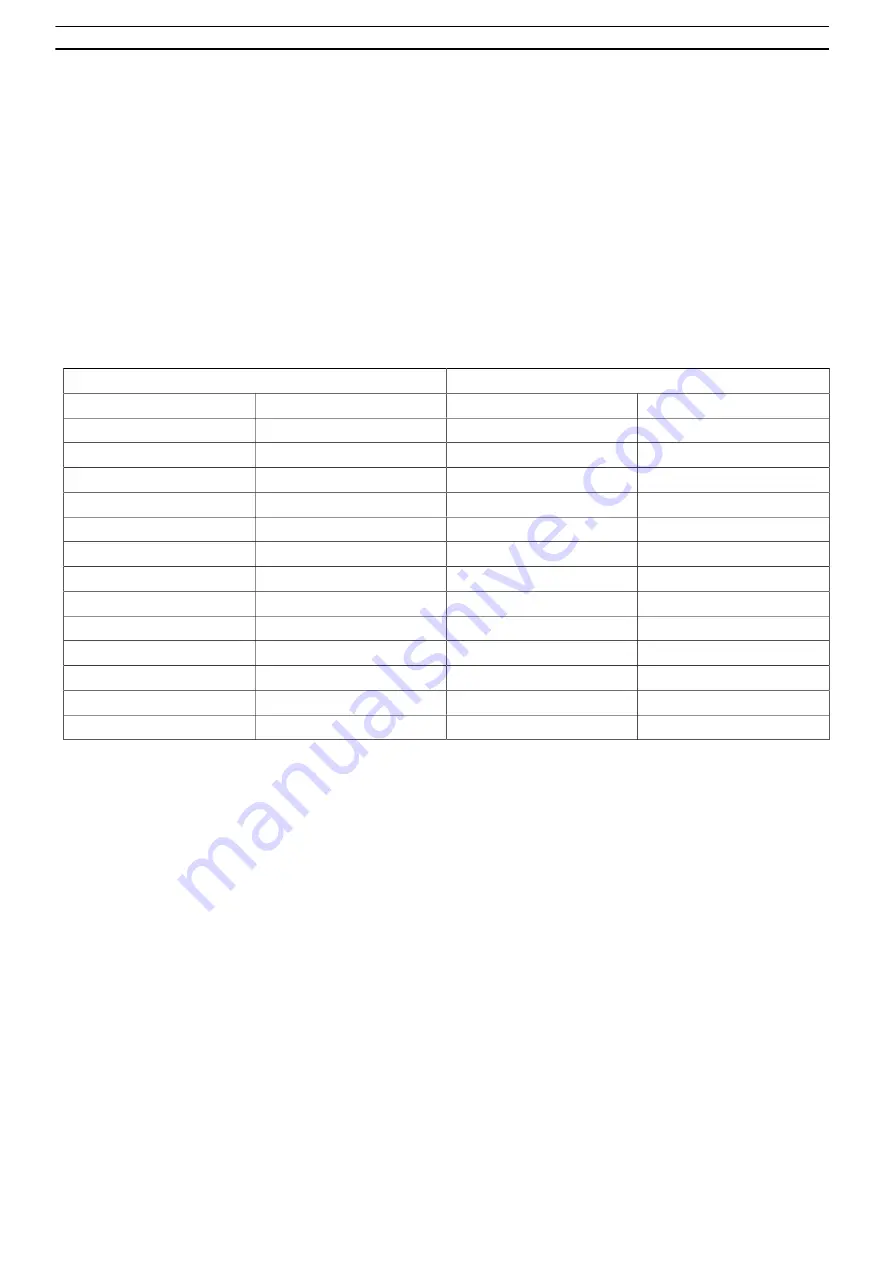

6.3.1.1. Table - Torque

Grade 5 (Class 8.8) hardware

Grade 8 (Class 10.9) hardware

Diameter

Torque

Diameter

Torque

1 /4”

13.6 Nm (10 lb-ft)

1 /4”

14.9 Nm (11 lb-ft)

5/16”

27.1 Nm (20 lb-ft)

5/16”

32.5 Nm (24 lb-ft)

3/8”

47.5 Nm (35 lb-ft)

3/8”

59.7 Nm (44 lb-ft)

7/16”

75 Nm (55 lb-ft)

7/16”

96.3 Nm (71 lb-ft)

1/2”

100 Nm (85 lb-ft)

1/2”

154.6 Nm (114 lb-ft)

5/8”

230 Nm (170 lb-ft )

5/8”

301 Nm (222 lb-ft)

3/4”

405 Nm (300 lb-ft)

3/4”

440.6 Nm (325 lb-ft)

M8

27.1 Nm (20 lb-ft)

M8

32.5 Nm (24 lb-ft)

M10

54.2 Nm (40 lb-ft)

M10

63.7 Nm (47 lb-ft)

M12

94.9 Nm (70 lb-ft)

M12

108.4 Nm (80 lb-ft)

M14

119.3 Nm (88 lb-ft)

M14

176.3 Nm (130 lb-ft)

M16

189.8 Nm (140 lb-ft)

M16

271.2 Nm (200 lb-ft)

M20

385 Nm (284 lb-ft)

M20

542.3 Nm (400 lb-ft)

6.4. Storage

If the loader is not used for a long period of time, apply

a thin layer of grease on any visible piston rods to help

protect them.

6.5. Transporting the loader

If the loader needs to be transported, e.g. for repairs, the

loader should either:

1. Be mounted on a tractor.

2. Transported without any implements, strapped to a

pallet with built-in stablizers.

3. Transported without any implements, only loaders with

built-in stablisers. When lifting the loader onto the

transportation vehicle, use the specified lifting points

for the loader.

Содержание 611TL

Страница 2: ......