CHAPTER 3. GENERAL HARDWARE INFORMATION

3.9. QUALIFIED PERSONNEL

3.8.2.2 Wear and Tear

The mobile robot has been designed for longest possible operational life and is almost maintenance free. It is never-

theless advisable to regularly check the robot and all related devices and components for signs of wear.

• Mechanical damages to operating elements, covers and other components will reduce protection against contact.

They might also cause delayed and surprising malfunctions.

• Damages, deformations or dirt on the drive and castor wheels can cause unsafe or inaccurate movements and

lead to loss of localisation.

• Vibrations and increased noises during operation can be indicators of something chafing or of mechanical over-

load.

• Unusual heat can point to mechanical or electrical overload or to batteries that are worn out and should be

replaced.

• A reduced uptime between charging cycles is often caused by old batteries that have lost a significant part of

their capacity.

3.8.2.3 Repairs

In case of any questions regarding repairs or replacement parts please get in touch with Neobotix. We are always

happy to support you.

Please mind the following points in any case:

• Only use replacement parts with features and properties identical to those of the original parts.

• Always mount all covers and hull parts properly and securely after finishing your work.

• Make sure to reconnect and fix all electrical connections, especially shieldings and earthing straps.

3.8.2.4 Batteries

The batteries need to be checked regularly and have to be replaced after some time. Additional information on the

batteries can be found at

(page 24).

3.9 Qualified Personnel

This product must only be modified, commissioned, operated and serviced by qualified personnel. Qualified personnel

are defined as persons who

• due to their specialist training and experience have adequate knowledge for the work at hand,

• have been instructed by the responsible robot operator in the operation of the robot or its parts and the currently

valid safety guidelines,

• are sufficiently familiar with the applicable official health and safety regulations, directives and generally recog-

nised engineering practice (e.g. DIN standards, VDE stipulations, engineering regulations from other EC mem-

ber states) that they can assess the work safety aspects of the product and

• have access to this manual and who have read it.

The following groups of persons are generally not considered qualified:

• Employees, interns or other academic staff not familiar with the product,

• visitors and quests,

39

Содержание MMO-700

Страница 1: ...MMO 700 Neobotix GmbH Apr 14 2022 ...

Страница 11: ...CHAPTER 1 MMO 700 1 6 TRANSPORT Fig 3 Position of the auxiliary batteries and battery connectors 7 ...

Страница 33: ...CHAPTER 3 GENERAL HARDWARE INFORMATION 3 4 CHARGING STATIONS Fig 2 Position of the main power switch X 29 ...

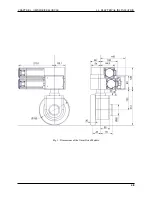

Страница 52: ...CHAPTER 4 OMNI DRIVE MODULE 4 4 ELECTRICAL INSTALLATION Fig 1 Dimensions of the Omni Drive Module 48 ...

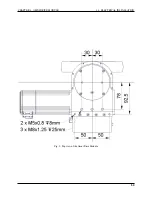

Страница 53: ...CHAPTER 4 OMNI DRIVE MODULE 4 4 ELECTRICAL INSTALLATION Fig 2 Bottom view of the Omni Drive Module 49 ...

Страница 54: ...CHAPTER 4 OMNI DRIVE MODULE 4 4 ELECTRICAL INSTALLATION Fig 3 Top view of the Omni Drive Module 50 ...