3-15

• ADJUSTING WHEN TENSION IS TIGHT (when measurement is above range for dimension A)

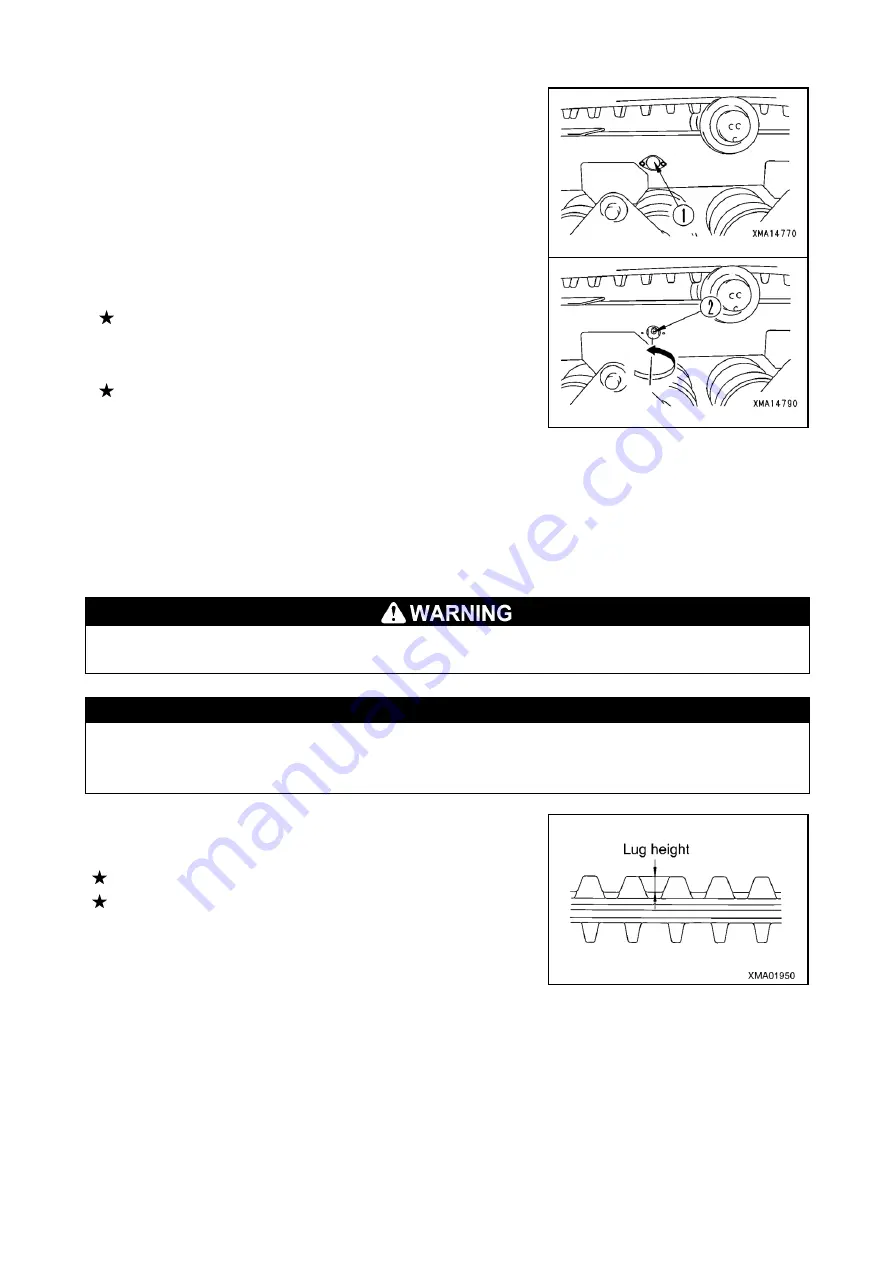

1. Remove 2 bolts, then remove grease valve cover (1).

2. Loosen valve (2) until dimension

A

is within the range given for “CHECKING

TENSION

”.

If the grease comes out slowly, push the idler end of the rubber crawler

strongly.

Never loosen valve (2) more than 1 turn.

If the grease still comes out slowly, start the engine and drive the machine

a short distance forward and backward.

3. Tighten valve (2) securely.

4. Drive the machine a short distance forward and backward to make the

tension uniform, then repeat the steps for “CHECKING TENSION” to

measure dimension

A

.

5. Install grease valve cover (1), then tighten the bolts.

[2] CHECK RUBBER CRAWLER FOR DAMAGE, WEAR

If there are any large cracks or damage to the rubber crawler, replace the rubber crawler immediately. There is

danger that the rubber crawler may break suddenly without warning during operations.

NOTICE

• When checking the rubber crawler, remove all mud and snow from the crawler before checking.

• Using the rubber crawler when it has exceeded the wear limit will cause slipping and will reduce the drawbar

pull. If the rubber crawler is in the following condition, replace it with a new rubber crawler.

• If the height of the lug is less than 1/3 of the standard dimension, replace the

rubber crawler.

Standard height: 40 mm

Wear limit: 14 mm

• If there are cracks or deep cuts and the wire in the core of the rubber crawler

can be seen, replace the rubber crawler.

Содержание MST-800VD

Страница 2: ......

Страница 6: ...A 4 ...

Страница 12: ...0 6 ...

Страница 34: ...1 22 ...

Страница 131: ...4 1 SPECIFICATIONS 1 DIMENSIONDRAWING 4 2 2 SPECIFICATIONSTABLE 4 3 ...

Страница 132: ...4 2 1 DIMENSION DRAWING CabSpecifications CanopySpecifications ...