RHT 64001-2800 Hand Crimp Tool

Doc No. ATS-640012800

Release Date: 05-30-03

UNCONTROLLED

COPY

Page 2 of 7

Revision: E

Revision Date: 12-06-06

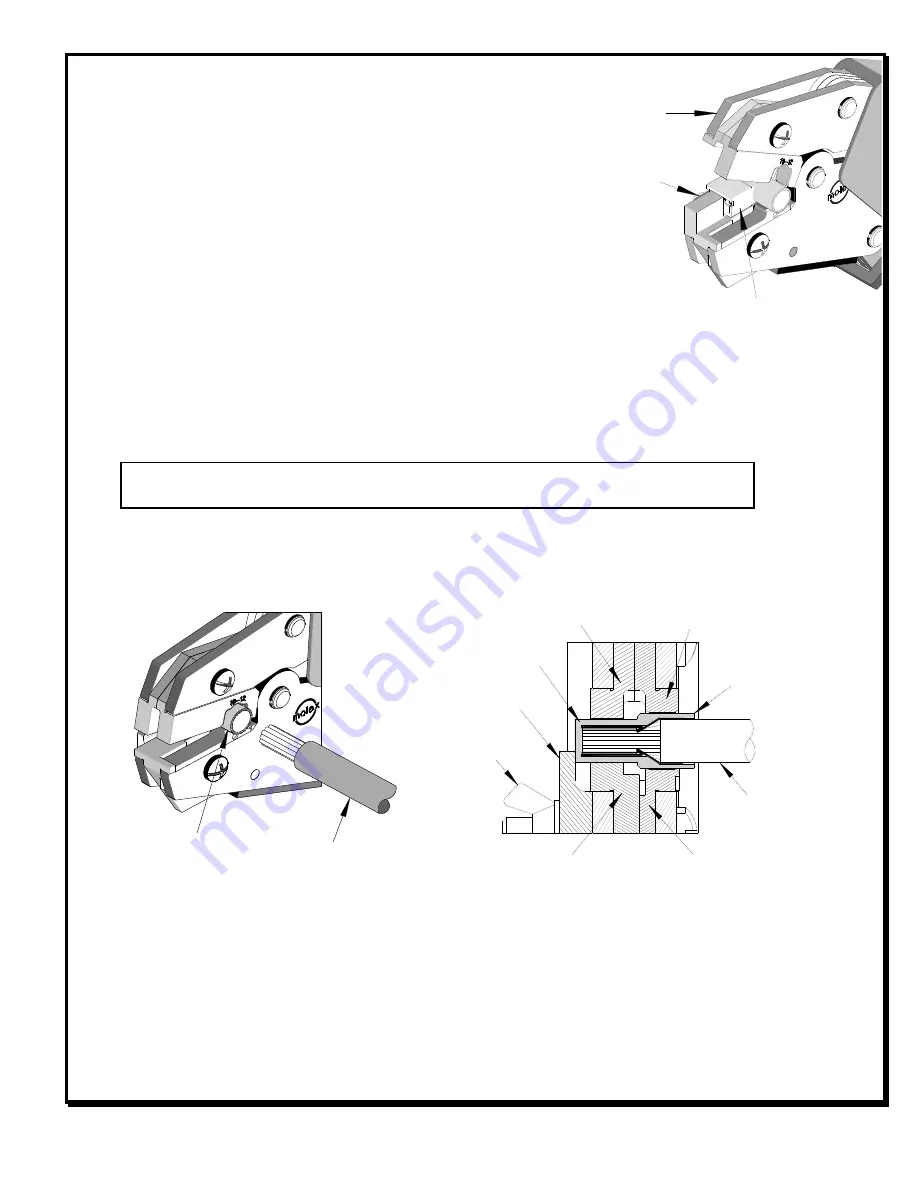

OPERATION

Open the tool by first closing the jaws sufficiently for the

ratchet mechanism to release.

Crimping Terminals

1. Insert the terminal with the barrel into the color-coded

nest and the square edge of the flag facing out. Make

sure the back of the flag terminal is against the

locator. See Figure 1. If terminal is not flush against

the locator loosen the M4 wing nut and adjust the

locator up or down so that the flat edge of the terminal is flush against the wall of the

locator. Tighten the M4 wing nut. See Figure 3.

2. Partially close the tool to hold the terminal in place shown in Figure 2.

3. Insert the properly stripped wire into the terminal barrel. See Figure 2 and 3. The wire

ends should butt against the inside of the connector. Cycle the tool.

Note

: The tamper proof ratchet action will not release the tool until it has

been fully closed.

4. Remove the crimped terminal. Inspect for proper crimp location, and check for

insulation closure.

5. If the insulation part of the crimp needs to be adjusted, first loosen the M4 screw on the

bottom tool jaw, then insert a 3/32 hex wrench (supplied) into the bottom of the lower

die. See Figure 4. A clockwise (CW) rotation decreases insulation crimp while a

counter-clockwise (CCW) rotation increases insulation crimp. After adjusting, retighten

the M4 screw.

TERMINAL

JAWS OPEN

Figure 1

LOCATOR

M4 WING NUT

Figure 2

TERMINAL

WIRE

FLAT EDGE

OF

TERMINAL

WIRE

INSULATIO

N

PUNCH

CONDUCTO

R

ANVI

L

INSULATION

ANVIL

Figure 3

CONDUCTO

R

PUNCH

TERMINA

L

BARREL

LOCATOR