14 - 15

MELSEC-A

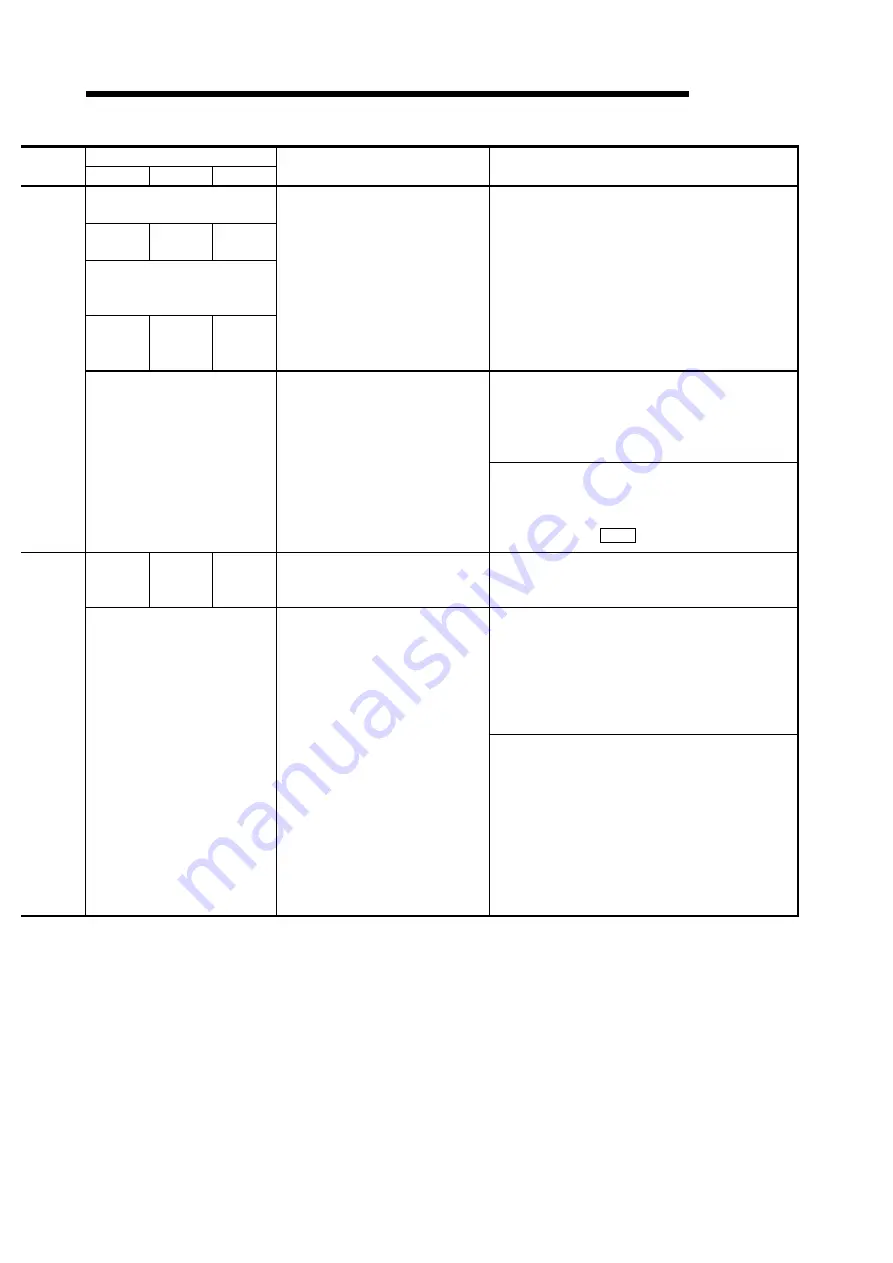

14 TROUBLESHOOTING

Relevant buffer memory address

Axis 1

Axis 2

Axis 3

Setting range

(Setting given in sequence program)

Remedy

Software stroke limit upper limit

value

16

17

166

167

316

317

Software stroke limit lower limit

value

18

19

168

169

318

319

<Software stroke limit upper/lower limit

value>

(In standard mode)

•

[mm] [inch] [pulse]

-2147483648 to 2147483647

•

[degree] 0 to 35999999

(In stepping motor mode)

•

[mm] [inch] [pulse]

-134217728 to 134217727

•

[degree] 0 to 35999999

Change the current feed to within the range of the

software stroke limit, using manual control operation (refer

to Chapter 11).

•

Correct the positioning address to within the range of the

software stroke limit.

•

Change the current feed to within the range of the

software stroke limit, using manual control operation

(refer to Chapter 11).

Refer to section “5.3 List of

positioning data.”

<Positioning address/movement

amount>

(In standard mode)

•

[mm] [inch] [pulse]

-2147483648 to 2147483647

•

[degree] 0 to 35999999

(In stepping motor mode)

•

[mm] [inch] [pulse]

-134217728 to 134217727

•

[degree] 0 to 35999999

Correct the positioning address/movement amount of the

positioning data to within the range of the software stroke

limit.

(Refer to section 5.3 Da. 5 )

1154

1155

1204

1205

1254

1255

<New current value>

[degree] 0 to 35999999

Change the new current value to within the setting range.

(Refer to section 9.2.10)

Do not designate the current value change in the

positioning data following continuous path control.

(Refer to section 9.2.10)

Refer to section “5.3 List of

positioning data.”

<Control method> 01

H

to 11

H

, 20

H

•

03

H

, 06

H

: 1 to 2 axis fixed-dimension

control

•

0D

H

, 0E

H

: Speed control

•

11

H

: Current value change

•

Speed/position changeover control:

0F

H

, 10

H

<Operation pattern> 00, 01, 11

•

01: Continuous positioning control

•

11: Continuous path control

•

Do not designate speed control, sizing feed, or

speed/position changeover control in the positioning data

following continuous path control.

•

Do not perform sizing feed, speed control, or

speed/position changeover control in the operation

pattern of continuous path control.

•

Do not perform speed control in the operation pattern of

continuous positioning control. (Refer to Chapter 9)

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Содержание A1SD75P1-S3

Страница 2: ...Artisan Technology Group Quality Instrumentation Guaranteed 888 88 SOURCE www artisantg com...

Страница 3: ...Artisan Technology Group Quality Instrumentation Guaranteed 888 88 SOURCE www artisantg com...

Страница 16: ...A 13 MEMO Artisan Technology Group Quality Instrumentation Guaranteed 888 88 SOURCE www artisantg com...

Страница 23: ...A 20 MEMO Artisan Technology Group Quality Instrumentation Guaranteed 888 88 SOURCE www artisantg com...

Страница 25: ...MEMO Artisan Technology Group Quality Instrumentation Guaranteed 888 88 SOURCE www artisantg com...

Страница 275: ...MEMO Artisan Technology Group Quality Instrumentation Guaranteed 888 88 SOURCE www artisantg com...

Страница 617: ...Index 12 MEMO Artisan Technology Group Quality Instrumentation Guaranteed 888 88 SOURCE www artisantg com...

Страница 620: ...Artisan Technology Group Quality Instrumentation Guaranteed 888 88 SOURCE www artisantg com...

Страница 621: ...Artisan Technology Group Quality Instrumentation Guaranteed 888 88 SOURCE www artisantg com...