Instructions and Cautions for

Safe Use of AC Servos

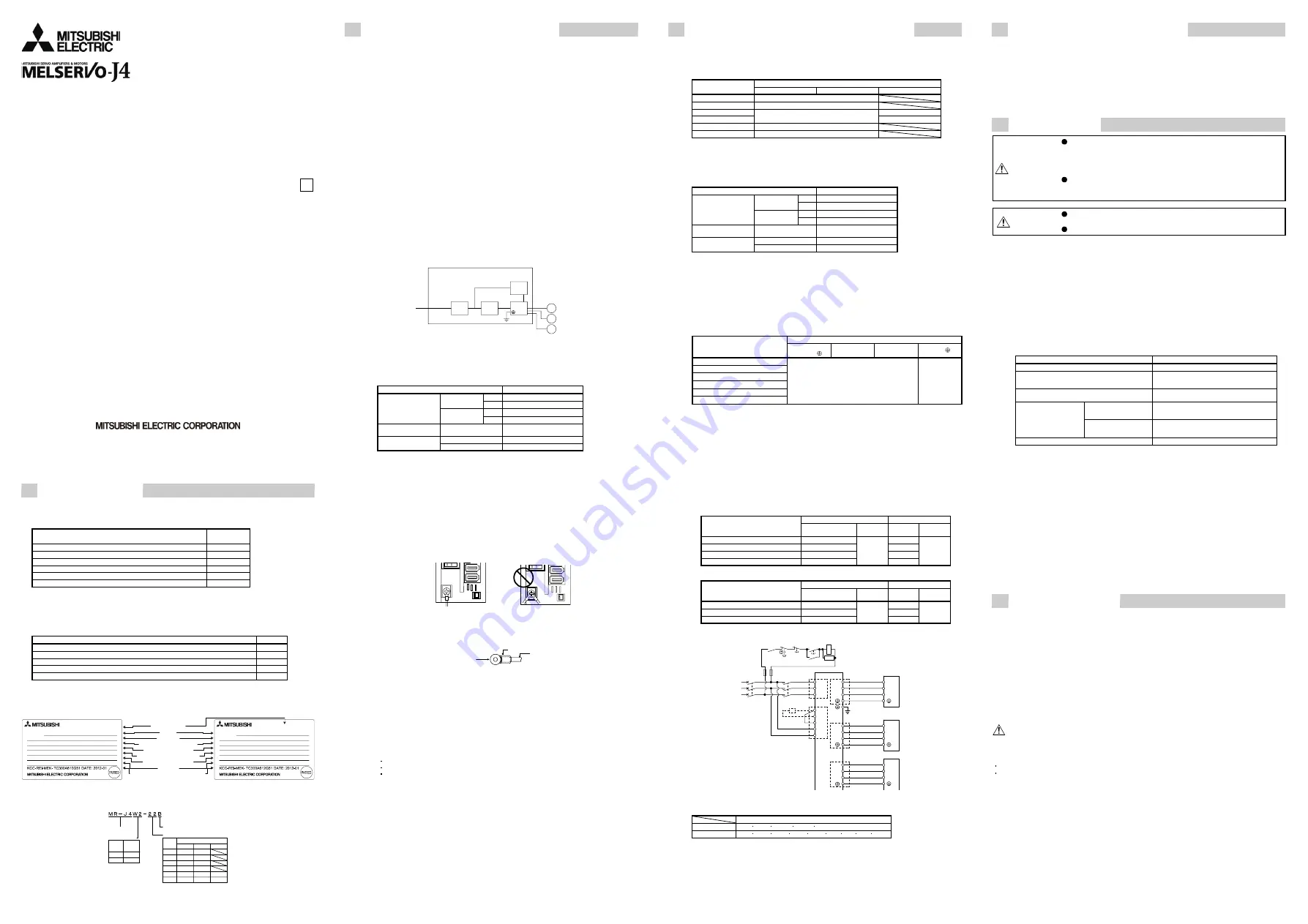

MR-J4W2-22B to MR-J4W2-1010B

MR-J4W3-222B and MR-J4W3-444B

MR-J4 Multi-axis Servo amplifier

General-Purpose AC Servo

C

IB(NA)0300176-C(1201)MEE

HEAD OFFICE: TOKYO BLDG MARUNOUCHI TOKYO 100-8310

Printed in Japan

This guide uses recycled paper.

Specifications subject to change without notice.

Country/Region

USA

Germany

Italy

China

Taiwan

Korea

Singapore

Sales office

Mitsubishi Electric Automation Inc.

500 Corporate Woods Parkway, Vernon Hills, IL 60061, USA

Mitsubishi Electric Europe B.V. German Branch

Gothaer Strasse 8, D-40880 Ratingen, Germany

Mitsubishi Electric Europe B.V. Italian Branch

Viale Colleoni 7

1-20041 Agrate Brianza (Milano), Italy

Mitsubishi Electric Automation (China) Ltd.

4F Zhi Fu Plazz, No. 80 Xin Chang Road

Shanghai 200003, China

Setsuyo Enterprise Co., Ltd.

6F, No.105 Wu-Kung 3rd Rd, Wu-Ku Hsiang, Taipei Hsine, Taiwan

Mitsubishi Electric Automation Korea Co., Ltd.

3F, 1480-6, Gayang-dong, Gangseo-gu, Seoul

157-200, Korea

Mitsubishi Electric Asia Pte, Ltd.

307 Alexandra Road #05-01/02,

Mitsubishi Electric Building Singapore 159943

Tel/Fax

Tel :+1-847-478-2100

Fax :+1-847-478-0327

Tel :+49-2102-486-0

Fax :+49-2102-486-1120

Tel :+39-39-60531

Fax :+39-39-6053312

Tel :+86-21-6120-0808

Fax :+86-21-6121-2444

Tel :+886-2-2299-2499

Fax :+886-2-2299-2509

Tel :+82-2-3660-9552

Fax :+82-2-3664-8372

Tel :+65-6470-2460

Fax :+65-6476-7439

AC Servo

1. INTRODUCTION

1.1 Introduction to the manuals

If this is the first time for you to use the MELSERVO-J4 Series, read the following manuals before use.

Please read them all carefully to use the MELSERVO-J4 Series safely.

Manual name

Manual No.

MELSERVO-J4W-_B Servo Amplifier Instruction Manual

SH(NA)030105

MELSERVO-J4 Servo Amplifier Instruction Manual (Troubleshooting)

SH(NA)030109

MELSERVO Servo Motor Instruction Manual (Vol.3)(Note1)

SH(NA)030113

MELSERVO Linear Servo Motor Instruction Manual (Note 2)

SH(NA)030110

MELSERVO Linear Encoder Instruction Manual (Note 2, 4)

SH(NA)030111

MELSERVO Direct Drive Motor Instruction Manual (Note 3)

SH(NA)030112

Note 1.

2.

3.

4.

It is necessary for using a rotary servo motor.

It is necessary for using a linear servo motor.

It is necessary for using a direct drive motor.

It is necessary for using a fully closed loop system (available in the future).

1.2 Contents of the packing

Unpack the product and check the rating plate to see if the servo motor is as you ordered.

Contents Quantity

Servo amplifier

1

Servo amplifier power supply connector CNP1/CNP2/CNP3A/CNP3B/CNP3C (Note)

1 each

Open tool for servo amplifier power supply connector

1

MELSERVO-J4 Series Instructions and Cautions for Safe Use of AC Servos (This installation guide)

1

Short-circuit connector CN8

1

Note. CNP3C is for MR-J4 3-axis servo amplifier.

1.3 Model code definition

(1) Rating plate

MODEL

TOKYO 100-8310, JAPAN

MADE IN JAPAN

MR-J4W2-22B

SER. S21001001

AC SERVO

POWER

INPUT

OUTPUT

STD.: IEC/EN61800-5-1 MAN.: IB(NA)0300176

Max. Surrounding Air Temp.: 55°C

IP20

: 200W×2 (A, B)

: 3AC/AC200-240V 2.9A/5.0A 50/60Hz

: 3PH170V 0-360Hz 1.5A×2(A, B)

MODEL

TOKYO 100-8310, JAPAN

MADE IN JAPAN

MR-J4W3-222B

SER. S21001001

AC SERVO

POWER

INPUT

OUTPUT

STD.: IEC/EN61800-5-1 MAN.: IB(NA)0300176

Max. Surrounding Air Temp.: 55°C

IP20 (Except for fan finger guard)

: 200W×3 (A, B, C)

: 3AC/AC200-240V 4.3A/7.5A 50/60Hz

: 3PH170V 0-360Hz 1.5A×3(A, B, C)

Serial number

Model

Capacity

Applicable power supply

Rated output current

Standard, Manual number

Ambient temperature

IP rating

KC mark number, The year and

month of manufacture

MR-J4 2-axis servo amplifier

MR-J4 3-axis servo amplifier

(2) Model

The following describes what each block of a model name indicates. Not all combinations of the symbols are

available.

Symbol

SSCNETIII/H interface

Rated output

Number of axis

Symbol

Rated output [kW]

44

22

77

A-axis

B-axis

C-axis

0.2

0.4

0.75

1

0.2

0.4

0.2

0.4

0.75

1

0.2

0.4

0.2

0.4

222

444

1010

Series

W2

W3

Number

of axis

2

3

2. COMPLIANCE WITH CE MARKING

This servo amplifier is designed to comply with EN61800-3 and EN61800-5-1 standard.

2.1 What is CE marking?

The CE marking is mandatory and must be affixed to specific products placed on the European Union. When a

product conforms to the requirements, the CE marking must be affixed to the product. The CE marking also applies

to machines and equipment incorporating servos.

(1) EMC directive

The EMC directive applies to the servo units alone. This servo is designed to comply with the EMC directive.

The EMC directive also applies the servo-incorporated machines and equipment. This requires the EMC filters

to be used with the servo-incorporated machines and equipment to comply with the EMC directive.

(2) Low voltage directive

The low voltage directive applies also to servo units alone. This servo is designed to comply with the low

voltage directive.

(3) Machinery directive (Compliance scheduled)

The MR-J4 series servo amplifiers comply with the safety component laid down in the Machinery directive.

Do not allow using the machine until the machine in which this servo amplifier is mounted is declared to comply

with the machinery directive.

2.2 For compliance

Be sure to perform an appearance inspection of every unit before installation. In addition, have a final performance

inspection on the entire machine/system, and keep the inspection record.

(1) Servo amplifiers and servo motors used

Use servo amplifiers and servo motors which standard product.

Servo amplifier: MR-J4W2-22B, MR-J4W2-44B, MR-J4W2-77B, MR-J4W2-1010B, MR-J4W3-222B

MR-J4W3-444B

Servo motor: HG-MR_, HG-KR_, HG-SR_

(2)

Structure

To comply with the CE marking, configure each equipment as follows.

Servo motor (Note)

M

M

M

Cabinet

Molded case

circuit breaker

Magnetic

contactor

Servo

amplifier

Reinforced

insulating type

24 V DC

power

supply

MC

MCCB

Note. This shows the MR-J4 3-axis servo amplifier. Two servo motors are connected for the MR-J4 2-

axis servo amplifier.

(3) Environment

(a) Operate the servo amplifier at pollution degree 2 or 1 set forth in EN 61800-5-1. For this purpose, install the

servo amplifier in a cabinet which is protected against water, oil, carbon, dust, dirt, etc. (IP54).

(b) Use the equipment under the following environment.

Item Environment

[°C]

0 to 55 (non-freezing)

Operation

[°F]

32 to 131 (non-freezing)

(Note)

Ambient temperature

[°C]

-20 to 65 (non-freezing)

Storage,

Transportation

[°F]

-4 to 149 (non-freezing)

Ambient humidity

Operation, Storage,

Transportation

90%RH or less (non-condensing)

Operation, Storage

1000 m or less

Altitude

Transportation

10000 m or less

Note. Ambient temperature is the internal temperature of the cabinet.

(4) Power supply

(a) This servo amplifier can be supplied from star-connected supply with grounded neutral point of overvoltage

category III set forth in EN 61800-5-1. However, when using the neutral point of 400 V system for single

phase supply, a reinforced insulating transformer is required in the power input section.

(b) The control circuit provides safe separation to the main circuit in the servo amplifier. For the interface power

supply, use a 24 V DC power supply with reinforced insulation on I/O terminals.

(5) Grounding

(a) To prevent an electric shock, always connect the protective earth (PE) terminal of the CNP3 connector of

the servo amplifier for grounding. Connect the grounding lead wire from the servo motor to the protective

earth (PE) terminal of the servo amplifier terminal block, and then connect the wire from the servo amplifier

to the ground via the protective earth (PE) of the cabinet.

(b) Do not connect two ground cable to the same protective earth (PE) terminal. Always connect cables to the

terminals one-to-one.

PE terminals

PE terminals

(c) If a leakage current breaker is used, always ground the protective earth (PE) terminal of the servo amplifier

to prevent an electric shock.

(6) Wiring

(a) The wires to be connected to the terminal block of the servo amplifier must have crimping terminals

provided with insulating tubes to prevent contact with adjacent terminals.

Insulating tube

Wire

Crimping terminal

(b) Use the servo motor-side power connector which complies with EN. The EN compliant power connector

sets are available from us as options.

(c) The servo amplifier must be installed in the metal cabinet.

(7) Peripheral devices, options

(a) Use the molded case circuit breaker and magnetic contactor models which are EN Standard-compliant

products given in the MR-J4 Series Servo Amplifier Instruction Manual. Use a residual current device

(RCD) of type B as necessary. When it is not used, provide insulation between the servo amplifier and

other device by double insulation or reinforced insulation, or install a transformer between the main power

supply and the servo amplifier.

Refer to Chapter 3 (7) for the compliance with molded case circuit breaker and fuse.

(b) The sizes of the wires given in the MR-J4 Series Servo Amplifier Instruction Manual meet the following

conditions. For use in any other conditions, follow Table 6 and Annex D of EN 60204-1.

Ambient temperature: 40 °C (104 °F)

Insulator: PVC (polyvinyl chloride)

Route the wires on wall surface or open cable tray.

(c) Use shielded wires for the power wires.

(d) Use the HF3000A-UN series EMC filter manufactured by Soshin Electric.

(e) Use a RSPD-250-U4 surge protector manufactured by Okaya Electric Industries.

(8) Performing EMC tests

When EMC tests are run on a machine/device into which the servo amplifier has been installed, it must

conform to the electromagnetic compatibility (immunity/emission) standards after it has satisfied the operating

environment/electrical equipment specifications.

(9) Short circuit rating (SCCR: Short Circuit Current Rating)

We confirmed in the short-circuit test that this servo amplifier is suitable for use in a circuit rated at 100 kA

RMS or less, and maximum voltage 500 V.

(10) Configuration diagram

Refer to Chapter 3 (8) for the compliance with configuration diagram.

3. COMPLIANCE WITH UL/CSA STANDARD

For the situation of safety certification, contact your local sales office.

This servo amplifier is designed to comply with UL 508C and CSA C22.2 No.14 standard.

(1) Servo amplifiers and servo motors used

Use servo amplifiers and servo motors which standard product.

Servo

motor

Servo amplifier

HG-MR HG-KR HG-SR

MR-J4W2-22B 053/13/23

MR-J4W2-44B 053/13/23/43

MR-J4W2-77B

51/52

MR-J4W2-1010B

43/73

51/52/81/102

MR-J4W3-222B 053/13/23

MR-J4W3-444B 053/13/23/43

(2) Installation

The MR-J4 series have been approved as the products which have been installed in a cabinet. The minimum

cabinet size is based on 150% of each MR-J4 combination. And also, design the cabinet so that the ambient

temperature in the cabinet is 55 °C (131 °F) or less.

The servo amplifier must be installed in the metal cabinet.

To ensure safety, do not touch the charging section for 15 minutes after power-off.

Item Environment

[°C]

0 to 55 (non-freezing)

Operation

[°F]

32 to 131 (non-freezing)

(Note)

Ambient temperature

[°C]

-20 to 65 (non-freezing)

Storage,

Transportation

[°F]

-4 to 149 (non-freezing)

Ambient humidity

Operation, Storage,

Transportation

90%RH or less (non-condensing)

Operation, Storage

1000 m or less

Altitude

Transportation

10000 m or less

Note. Ambient temperature is the internal temperature of the cabinet.

(3) Short circuit rating (SCCR: Short Circuit Current Rating)

We confirmed in the short-circuit test that this servo amplifier is suitable for use in a circuit rated at 100 kA

RMS or less, and maximum voltage 500 V.

(4) Overload protection characteristics

Servo amplifier MR-J4W series has solid-state servo motor overload protection for each axis. (It is set on the

basis (full load current) of 120% rated current of the servo amplifier.)

(5) Selection example of wires

To comply with the UL/CSA Standard, use UL-approved copper wires rated at 75 °C (167 °F) for wiring.

Wire [AWG]

Servo amplifier

(Note 1)

L1/L2/L3/

L11/L21 P+/C/D U/V/W/

MR-J4W2-22B

MR-J4W2-44B

MR-J4W2-77B

MR-J4W2-1010B

MR-J4W3-222B

MR-J4W3-444B

14

(Note

2)

Note 1.

2.

Use the crimping terminal specified as below for the PE terminal of the servo amplifier.

Crimping terminal: FVD2-4

Tool (body): YNT-1614

Manufacturer: JST

Tightening torque: 1.2 [N•m]

The wire size depends on the servo motor characteristics.

(6) About wiring protection

For installation in United States, branch circuit protection must be provided, in accordance with the National

Electrical Code and any applicable local codes.

For installation in Canada, branch circuit protection must be provided, in accordance with the Canada Electrical

Code and any applicable provincial codes.

(7) Options, peripheral devices

Use the UL/CSA Standard-compliant products.

Use the molded case circuit breaker (UL489 Listed MCCB) or a Class T fuse indicated in the table below.

(a) MR-J4W2

Molded case circuit breaker

Fuse

Servo motor total output

Current

Voltage AC

[V]

Current [A] Voltage AC

[V]

400 W or less

50 A frame 5 A

10

From over 400 W to 900 W

50 A frame 10 A

15

From over 900 W to 1.6 kW

50 A frame 15 A

240

20

300

From over 1.6 kW to 2 kW

50 A frame 20 A

30

(b) MR-J4W3

Molded case circuit breaker

Fuse

Servo motor total output

Current

Voltage AC

[V]

Current

[A]

Voltage AC

[V]

400 W or less

50 A frame 5 A

10

From over 400 W to 900 W

50 A frame 10 A

15

300

From over 900 W to 1.2 kW

50 A frame 15 A

240

20

(8) Connection example

Servo amplifier

CNP2

P+

C

D

Regenerative

option

CNP1

U

V

W

U

V

W

Servo motor

CNP3A

U

V

W

U

V

W

Servo motor

CNP3B

U

V

W

U

V

W

Servo motor

CNP3C

Malfunction

RA1

OFF

MC

ON

M

C

SK

EMG stop

switch

L11

L21

L1

L2

L3

Power

supply

MC

MCCB

or fuse

(9) Power supply

The control circuit provides safe separation to the main circuit in the servo amplifier.

Connector/terminal

Main circuit

CNP1 CNP2 CNP3A CNP3B CNP3C

Control circuit

CN1A CN1B CN2A CN2B CN2C CN3 CN4 CN5 CN8

4. COMPLIANCE WITH KC MARK

For the situation of compliance, contact your local sales office.

Note the following when using the product in South Korea.

이

기기는

업무용

(A

급

)

전자파적합기기로서

판

매자

또는

사용자는

이

점을

주의하시기

바라며

,

가정외의

지역에서

사용하는

것을

목적으

로

합니다

.

(The product is for business use (Class A) and meets the electromagnetic compatibility

requirements. The seller and the user must note the above point, and use the product in a place

except for home.)

5. INSPECTION

WARNING

Before starting maintenance and/or inspection, turn off the power and

wait for 15 minutes or more until the charge lamp turns off. Otherwise, an

electric shock may occur. In addition, when confirming whether the

charge lamp is off or not, always confirm it from the front of the servo

amplifier.

To avoid an electric shock, only qualified personnel should attempt

inspections. For repair and parts replacement, contact your local sales

office.

CAUTION

Do not perform insulation resistance test on the servo amplifier.

Otherwise, it may cause a malfunction.

Do not disassemble and/or repair the equipment on customer side.

(1) Inspection

It is recommend that the following points periodically be checked.

(a) Check for loose terminal block screws. Retighten any loose screws.

(b) Check the cables and the like for scratches and cracks. Inspect them periodically according to operating

conditions especially when the servo motor is movable.

(c) Check that the connector is securely connected to the servo amplifier.

(d) Check that the wires are not coming out from the connector.

(e) Check for dust accumulation on the servo amplifier.

(f) Check for unusual noise generated from the servo amplifier.

(2) Parts having service lives

Service lives of the following parts are listed below. However, the service lives vary depending on operating

methods and environment. If any fault is found in the parts, they must be replaced immediately regardless of

their service lives. For parts replacement, please contact your local sales office.

Part name

Life guideline

Smoothing capacitor

10 years

Relay

Number of power-on and number of emergency stop

times: 100,000 times

Number of on and off for STO: 1,000,000 times

Cooling fan

50,000 hours to 70,000 hours

(7 years to 8 years)

Rotary servo motor

Approximately 40,000 hours/2 axes, 30,000 hours/3

axes, or 10,000 hours/8 axes (equipment power

supply: off, ambient temperature: 20 °C (68 °F))

(Note 1) Battery backup time

Direct drive motor

Approximately 10,000 hours/2 axes, 7,000 hours/3

axes, or 2,000 hours/8 axes (equipment power supply:

off, ambient temperature: 20 °C (68 °F))

(Note 2) Battery life

5 years from date of manufacture

Note 1.

2.

The data-holding time using five batteries of MR-BAT6V1 on condition that the power supply of the servo

amplifier is off. Replace the batteries within 3 years since the operation start whether the power supply of the

servo amplifier is on/off.

Quality of the batteries degrades by the storage condition. The battery life is 5 years from the production date

regardless of the connection status.

(a) Smoothing capacitor

Affected by ripple currents, etc. and deteriorates in characteristic. The life of the capacitor greatly depends

on ambient temperature and operating conditions. The capacitor will reach the end of its life in 10 years of

continuous operation in normal air-conditioned environment (40 °C (104 °F) surrounding air temperature or

less).

(b) Relays

Contact faults will occur due to contact wear arisen from switching currents. Relays reach the end of their

lives when the power is turned on and emergency stop occurs 100,000 times in total, or when the STO has

been turned on and off 1,000,000 times while the servo motor is stopped under servo-off state. However,

the lives of relays may depend on the power supply capacity.

(c) Servo amplifier cooling fan

The cooling fan bearings reach the end of their life in 50,000 hours to 70,000 hours. Normally, therefore,

the cooling fan must be changed in seven or eight years of continuous operation as a guideline. It must also

be changed if unusual noise or vibration is found during inspection.

The life indicates under the yearly average ambient temperature of 40 °C (104 °F), free from corrosive gas,

flammable gas, oil mist, dust and dirt.

6. ALARM/WARNING

For details on each type of alarms or warnings, refer to MELSERVO-J4 Servo Amplifier Instruction Manual

(Troubleshooting).

●

DISPOSAL OF WASTE

●

Please dispose a servo amplifier, battery (primary battery) and other options according to your local

laws and regulations.

Battery transportation

To transport lithium batteries, take actions to comply with the instructions and regulations such as

the United Nations (UN), the International Civil Aviation Organization (ICAO), and the International

Maritime Organization (IMO).

EEP-ROM life

The number of write times to the EEP-ROM, which stores parameter settings, etc., is limited to

100,000. If the total number of the following operations exceeds 100,000, the servo amplifier may

malfunction when the EEP-ROM reaches the end of its useful life.

Write to the EEP-ROM due to parameter setting changes

Write to the EEP-ROM due to device changes