140

5.2.5

OPR basic parameters

(1) [Pr.43] OPR method

Set the "OPR method" for carrying out machine OPR.

Refer to

Page 318, Section 8.2 for details on the OPR methods.

(2) OPR method

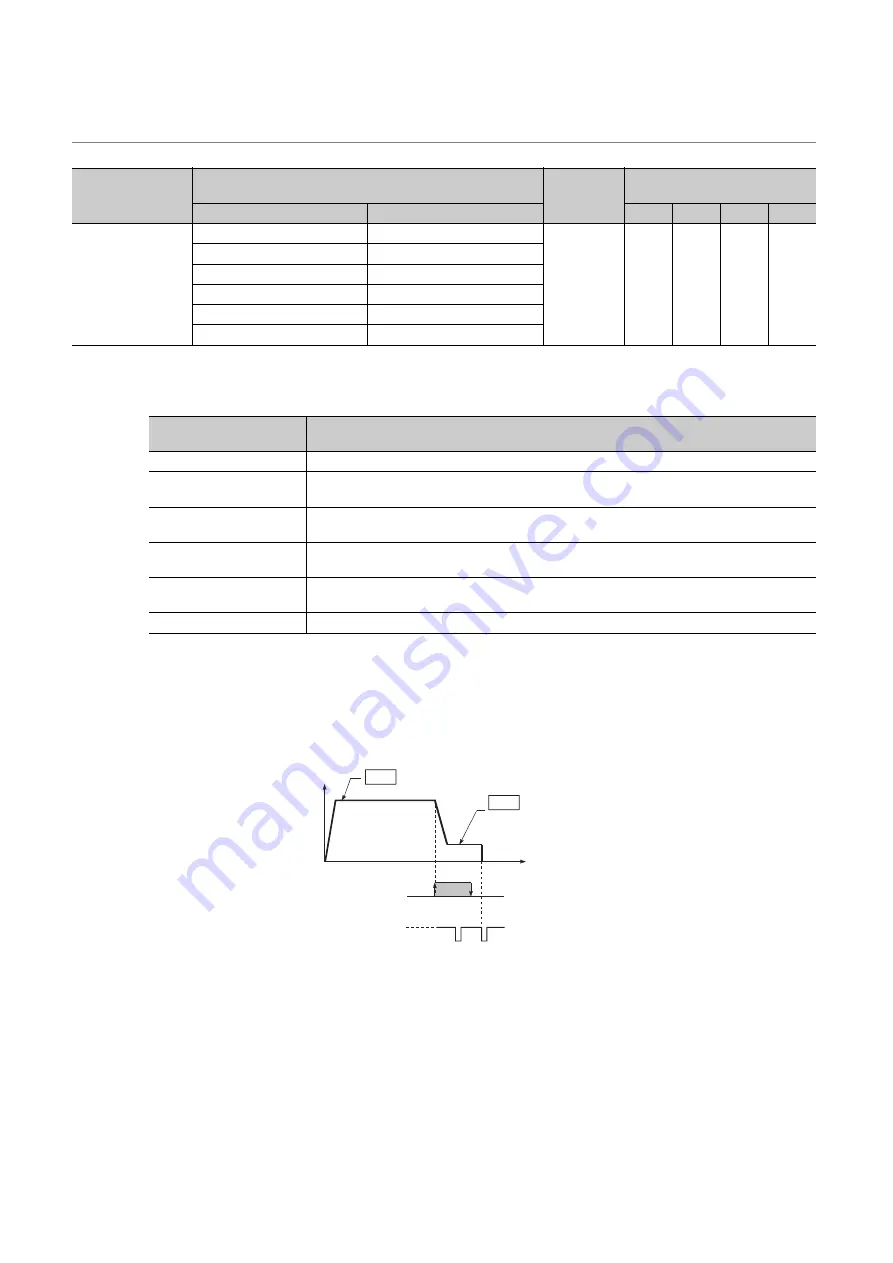

(a) 0: Near-point dog method

1.

Start machine OPR. (Start movement at the "[Pr.46] OPR speed" in the "[Pr.44] OPR direction".)

2.

The machine begins decelerating when the near-point dog ON is detected.

3.

The machine decelerates to the "[Pr.47] Creep speed", and subsequently moves at that speed. (At

this time, the near-point dog must be ON. If the near-point dog is OFF, the machine will decelerate

to a stop.)

4.

At the first zero signal (one pulse output at one motor revolution) after the near-point dog OFF, the

pulse output from the LD75 stops, and the machine OPR is completed.

Item

Setting value, setting range

Default value

Setting value buffer memory

address

Value set with GX Works2

Value set with program

Axis 1

Axis 2

Axis 3

Axis 4

[Pr.43] OPR method

0: Near-point dog method

0

0

70

220

370

520

1: Stopper method 1)

1

2: Stopper method 2)

2

3: Stopper method 3)

3

4: Count method 1)

4

5: Count method 2)

5

Selection of [Pr.43] OPR

method

OPR operation

0: Near-point dog method

After decelerating at the near-point dog ON, stop at the zero signal and complete the machine OPR.

1: Stopper method 1)

After decelerating at the near-point dog ON, stop with the stopper, and complete the machine OPR after the

dwell time has passed.

2: Stopper method 2)

After decelerating at the near-point dog ON, stop with the stopper, and complete the machine OPR with the

zero signal.

3: Stopper method 3)

After starting with the creep speed, stop with the stopper, and complete the machine OPR with the zero

signal.

4: Count method 1)

After decelerating at the near-point dog ON, move the designated distance, and complete the machine OPR

with the zero signal.

5: Count method 2)

After decelerating at the near-point dog ON, move the designated distance, and complete the machine OPR.

t

1.

2.

3.

4.

ON

OFF

V

Near-point dog

Zero signal

OPR speed

Pr.46

Pr.47

Creep speed

Содержание MELSEC-L LD75D

Страница 1: ...MELSEC L LD75P LD75D Positioning Module User s Manual LD75P1 LD75P2 LD75P4 LD75D1 LD75D2 LD75D4 ...

Страница 2: ......

Страница 11: ...9 Memo ...

Страница 47: ...45 CHAPTER 2 SYSTEM CONFIGURATION 2 2 1 General Image of System 1 When connected to a CPU module ...

Страница 176: ...174 ...

Страница 264: ...262 ...

Страница 266: ...264 ...

Страница 267: ...265 CHAPTER 6 PROGRAM USED FOR POSITIONING CONTROL 6 6 4 Positioning Program Examples ...

Страница 268: ...266 ...

Страница 269: ...267 CHAPTER 6 PROGRAM USED FOR POSITIONING CONTROL 6 6 4 Positioning Program Examples ...

Страница 270: ...268 ...

Страница 271: ...269 CHAPTER 6 PROGRAM USED FOR POSITIONING CONTROL 6 6 4 Positioning Program Examples ...

Страница 272: ...270 Z ABRST1 instruction execution ...

Страница 273: ...271 CHAPTER 6 PROGRAM USED FOR POSITIONING CONTROL 6 6 4 Positioning Program Examples ...

Страница 278: ...276 ...

Страница 279: ...277 CHAPTER 6 PROGRAM USED FOR POSITIONING CONTROL 6 6 4 Positioning Program Examples ...

Страница 280: ...278 ...

Страница 281: ...279 CHAPTER 6 PROGRAM USED FOR POSITIONING CONTROL 6 6 4 Positioning Program Examples ...

Страница 282: ...280 ...

Страница 283: ...281 CHAPTER 6 PROGRAM USED FOR POSITIONING CONTROL 6 6 4 Positioning Program Examples ...

Страница 284: ...282 ...

Страница 285: ...283 CHAPTER 6 PROGRAM USED FOR POSITIONING CONTROL 6 6 4 Positioning Program Examples ...

Страница 286: ...284 ...

Страница 287: ...285 CHAPTER 6 PROGRAM USED FOR POSITIONING CONTROL 6 6 4 Positioning Program Examples ...

Страница 316: ...314 Memo ...

Страница 685: ...683 APPENDICES A Appendix 1 Function Update Appendix 1 1 Function comparison Memo ...

Страница 738: ...736 Memo ...

Страница 806: ...804 5 LD75D2 Unit mm 6 LD75D4 Unit mm 45 4 90 4 95 4 45 45 DIN rail center 45 4 90 4 95 4 45 45 DIN rail center ...

Страница 817: ......