D700 QUICK START MANUAL

7

14. If the machine must not be restarted when power is restored after

a power failure, provide a magnetic contactor in the inverter’s input

side and also make up a sequence which will not switch on the

start signal. If the start signal (start switch) remains on after a power

failure, the inverter will automatically restart as soon as the power is

restored.

15. Instructions for overload operation When performing operation of

frequent start/stop of the inverter, rise/fall in the temperature of

the transistor element of the inverter will repeat due to a repeated

flow of large current, shortening the life from thermal fatigue. Since

thermal fatigue is related to the amount of current, the life can be

increased by reducing current at locked condition, starting current,

etc. Decreasing current may increase the life. However, decreasing

current will result in insufficient torque and the inverter may not

start. Therefore, choose the inverter which has enough allowance

for current (up to 2 rank larger in capacity).

16. Make sure that the specifications and rating match the system

requirements. (17) When the motor speed is unstable, due to

change in the frequency setting signal caused by electromagnetic

noises from the inverter, take the following measures while applying

the motor speed by the analog signal.

• Do not run the signal cables and power cables (inverter I/O cables)

in parallel with each other and do not bundle them.

• Run signal cables as far away as possible from power cables

(inverter I/O cables).

• Use shield cables as signal cables.

• Install a ferrite core on the signal cable (Example: ZCAT3035-1330

TDK).

6. FAILSAFE OF THE SYSTEM WHICH

USES THE INVERTER

When a fault occurs, the inverter trips to output a fault signal. However,

a fault output signal may not be output at an inverter fault occurrence

when the detection circuit or output circuit fails, etc. Although Mitsubishi

assures best quality products, provide an interlock which uses inverter

status output signals to prevent accidents such as damage to machine

when the inverter fails for some reason and at the same time consider

the system configuration where failsafe from outside the inverter,

without using the inverter, is enabled even if the inverter fails.

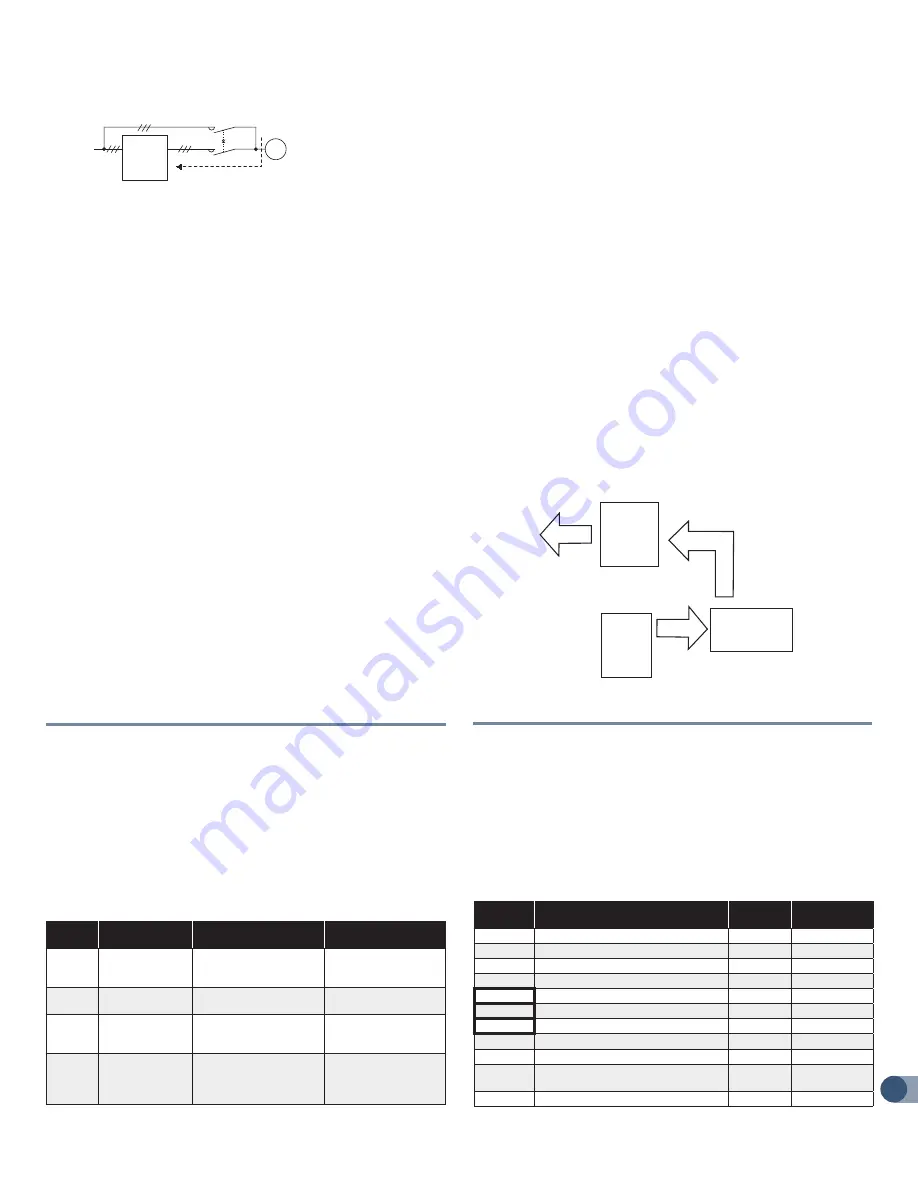

1. Interlock method which uses the inverter status output signals By

combining the inverter status output signals to provide an interlock

as shown below, an inverter alarm can be detected.

No

Interlock Method Check

Method Used

Signals

1

Inverter protective

function operation

Operation check of an

alarm contact Circuit error

detection by negative logic

Fault output signal (ALM

signal)

2

Inverter running

status

Operation ready signal

check

Operation ready signal

(RY signal)

3

Inverter running

status

Logic check of the start

signal and running signal

Start signal (STF signal,

STR signal) Running

signal (RUN signal)

4

Inverter running

status

Logic check of the start

signal and output current

Start signal (STF signal,

STR signal) Output

current detection signal

(Y12 signal)

Backup method outside the inverter

Even if the interlock is provided by the inverter status signal, enough

failsafe is not ensured depending on the failure status of the inverter

itself. For example, even if the interlock is provided using the inverter

fault output signal, start signal and RUN signal output, there is a case

where a fault output signal is not output and RUN signal is kept output

even if an inverter fault occurs. Provide a speed detector to detect

the motor speed and current detector to detect the motor current and

consider the backup system such as checking up as below according

to the level of importance of the system.

• Start signal and actual operation check Check the motor running

and motor current while the start signal is input to the inverter

by comparing the start signal to the inverter and detected speed

of the speed detector or detected current of the current detector.

Note that the motor current runs as the motor is running for the

period until the motor stops since the inverter starts decelerating

even if the start signal turns OFF. For the logic check, configure a

sequence considering the inverter deceleration time. In addition, it

is recommended to check the three-phase current when using the

current detector.

• Command speed and actual operation check Check if there is

no gap between the actual speed and commanded speed by

comparing the inverter speed command and detected speed of the

speed detector.

7. PARAMETER LIST

For simple variable-speed operation of the inverter, the initial setting

of the parameters may be used as they are. Set the necessary

parameters to meet the load and operational specifications. Parameter

setting, change and check can be made from the operation panel. For

details of parameters, refer to the instruction manual.

NOTES

* indicates simple mode parameters.

• The parameters surrounded by a black border in the table allow its

setting to be changed during operation even if “0” (initial value) is set

in Pr. 77 Parameter write selection.

Parameter

Name

Setting

Range

Initial Value

*0

Torque boost

0 to 30%

6/4/3% *1

*1

Maximum frequency

0 to 120Hz 120Hz

*2

Minimum frequency

0 to 120Hz 0Hz

*3

Base frequency

0 to 400Hz 60Hz

*4

Multi-speed setting (high speed)

0 to 400Hz 60Hz

*5

Multi-speed setting (middle speed)

0 to 400Hz 30Hz

*6

Multi-speed setting (low speed)

0 to 400Hz

10Hz

*7

Acceleration time

0 to 3600s 5/10s *2

*8

Deceleration time

0 to 3600s 5/10s *2

*9

Electronic thermal O/L relay

0 to 500A

Rated inverter

current

10

DC injection brake operation frequency

0 to 120Hz 3Hz

Power

supply

Inverter

Undesirable current

MC2

MC1

Interloc

U

V

W

R/L1

S/L2

T/L3

IM

Inverter

Controller

System failure

To the alarm detection sensor

Sensor

(speed, temperature,

air volume, etc.)

MitsubishiElectric Automation, Inc.