4. Consumable Item Replacement

20

6

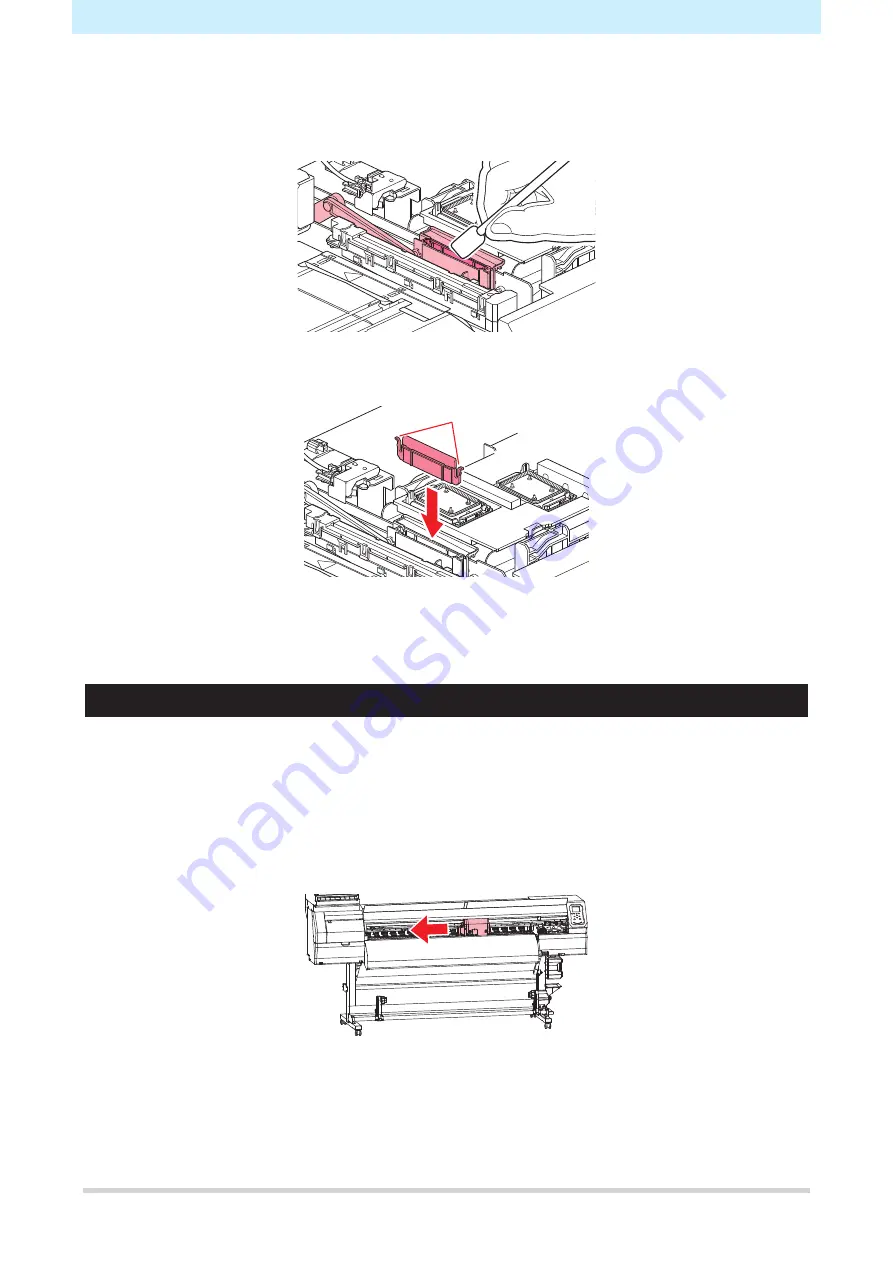

Wipe away any ink or dust adhering to the wiper slider.

• Wipe off any ink adhering with a clean stick moistened with maintenance liquid.

• Wipe off the maintenance liquid. Make sure none remains.

7

Insert a new wiper.

Lug

8

Once replacement is complete, close the front cover, then press the [ENTER] key.

• The wiper usage count is reset.

Wiper Cleaner Replacement

Replace with a new wiper cleaner once a year.

1

On the LOCAL mode screen, select [MENU] > [Maintenance], then press the [ENTER] key.

• The Maintenance menu is displayed.

2

Select [Station] > [Carriage Out] > [Move To Platen Right End ], then press the [ENTER] key.

• The carriage moves over the platen.

3

Open the front cover.

Содержание jV100-160

Страница 32: ......

Страница 33: ......

Страница 34: ......

Страница 36: ...MIMAKI ENGINEERING CO LTD 2020 YM FW 1 0...