2

3

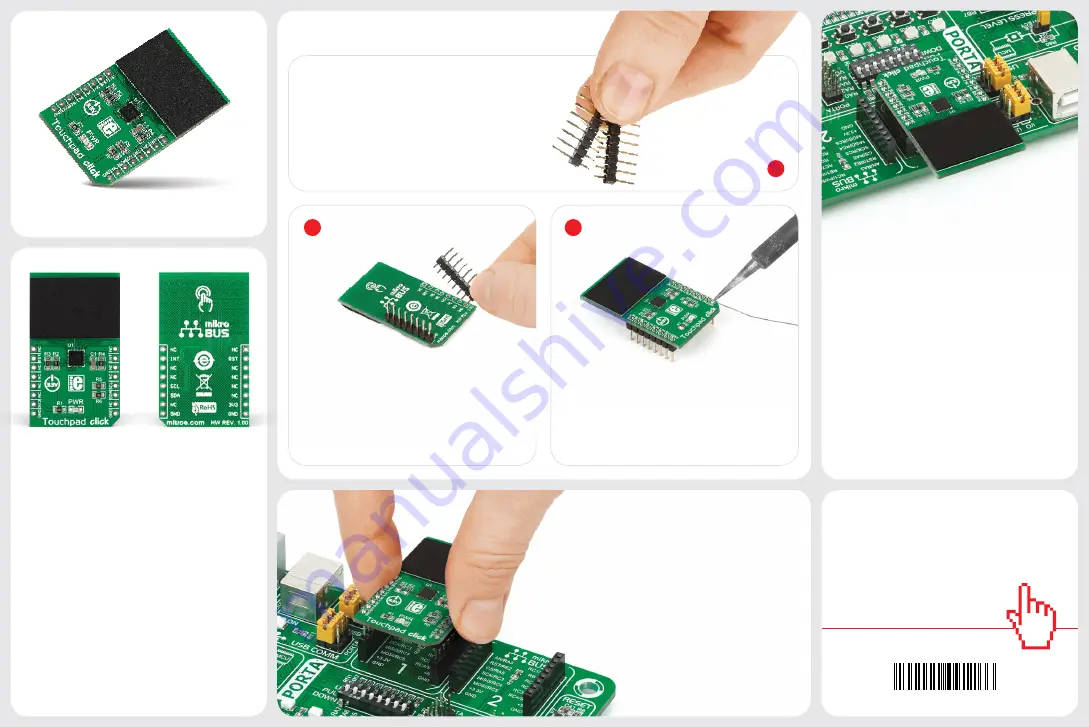

2. Soldering the headers

3. Plugging the board in

Once you have soldered the headers your

board is ready to be placed into the desired

mikroBUS

™

socket. Make sure to align the cut

in the lower-right part of the board with the

markings on the silkscreen at the mikroBUS

™

socket. If all the pins are aligned

correctly, push the board all the

way into the socket.

Turn the board upward again. Make sure

to align the headers so that they are

perpendicular to the board, then solder the

pins carefully.

Turn the board upside down so that

the bottom side is facing you upwards.

Place shorter pins of the header into the

appropriate soldering pads.

Before using your click board

™

, make sure

to solder 1x8 male headers to both left and

right side of the board. Two 1x8 male headers

are included with the board in the package.

4. Essential features

The MTCH6102 device supports taps,

doubletaps, swipes and scrolling gestures.

The small capacitive surface is optimized

for sungle-finger applications. The sensor

outputs 12-bit resolution coordinate

data (the I2C interface supports up to

400 kbps transfer rates). MTCH6102 also

incorporates power-saving features, such

as a configurable frame rate for sleep/idle

modes, as well as a separate standby and

active mode.

1

Touchpad click is a capacitive touch

input device driven by Microchip’s low-

powered

MTCH6102 controller

. The

touchpad surface is covered with a sheet

of black plastic to demonstrate the chip’s

support for cover layers (up to 3mm for

plastic, 5mm for glass) Touchpad click

communicates with the target MCU through

the mikroBUS™ I2C interface (SCL and SDA

pins), with additional functionality provided

by the Interrupt and RSTL pins. Designed to

use a 3.3V power supply.

1. Introduction

Touchpad click Manual v100

0100000091166

click

BOARDS

™

www.mikroe.com

Touchpad

click

Touchpad click Manual v100