2

3

OLED W click Manual v100

0 100000 027073

click

™

BOARD

www.mikroe.com

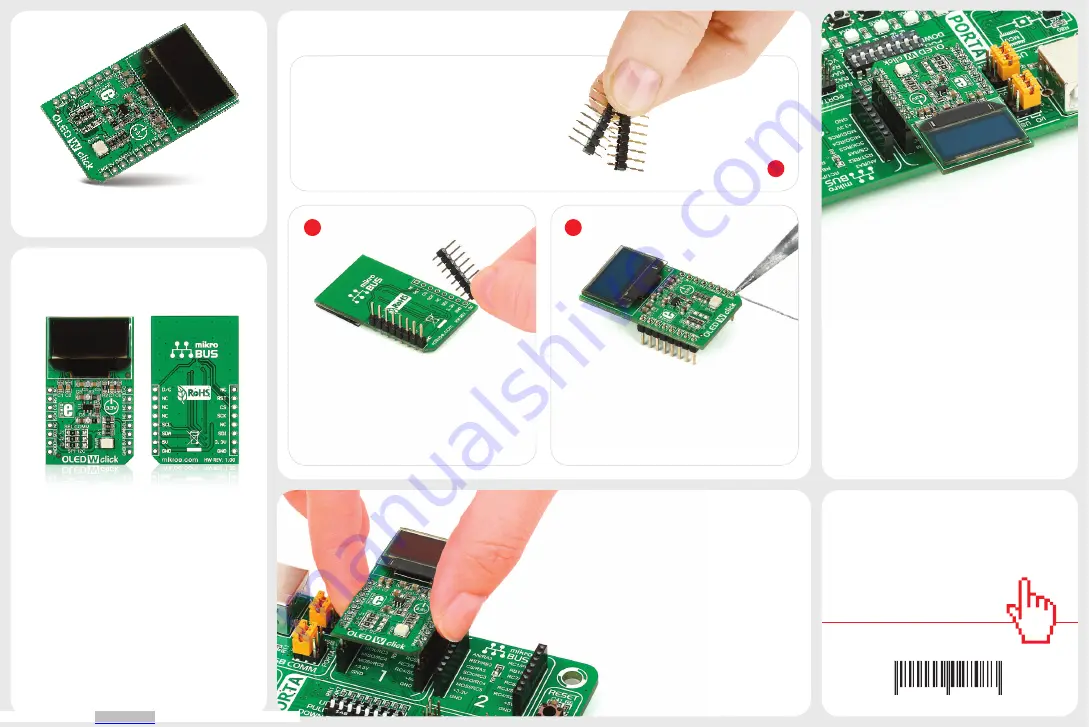

2. Soldering the headers

1. Introduction

3. Plugging the board in

Once you have soldered the headers your

board is ready to be placed into the desired

mikroBUS

™

socket. Make sure to align the

cut in the lower-right part of the board with

the markings on the silkscreen at the

mikroBUS

™

socket. If all the pins

are aligned correctly, push the

board all the way into the socket.

Turn the board upward again. Make sure

to align the headers so that they are

perpendicular to the board, then solder

the pins carefully.

Turn the board upside down so that

the bottom side is facing you upwards.

Place shorter pins of the header into the

appropriate soldering pads.

Before using your click

™

board, make sure

to solder 1x8 male headers to both left

and right side of the board. Two 1x8 male

headers are included with the board in

the package.

4. Essential features

1

OLED displays are made from a thin film of

organic compound that emits light when

exposed to a current. Small monochrome

displays like these are ideal for displaying

text or icons. They are bright, have a wide

viewing angle and low power consumption.

The display on OLED W click

™

is 19.3 x 7.8mm

with a 96 x 39px resolution. The SSD1306

controller has built-in functionalities like

contrast control, normal or inverse image

display, vertical and horizontal scrolling

functions and many more.

OLED W

click

™

OLED W click

™

lets you add a small but bright

and crisp display to your design. It carries

a white monochrome passive matrix OLED

display and a

SSD1306

IC to control it. OLED

W click

™

can communicate with the target

board either through SPI or I

2

C interfaces.

mikroBUS

™

lines used for SPI are CS, SCK,

and MOSI (SDI); I

2

C output uses SCL and SDA

lines; also, both modes use PWM (A/C) and

RST lines. You select between SPI and I

2

C

outputs by resoldering three jumpers. OLED

W click

™

uses a 3.3V power supply.

Downloaded from