T2

T1

T2

T2

T1

T1 + T2

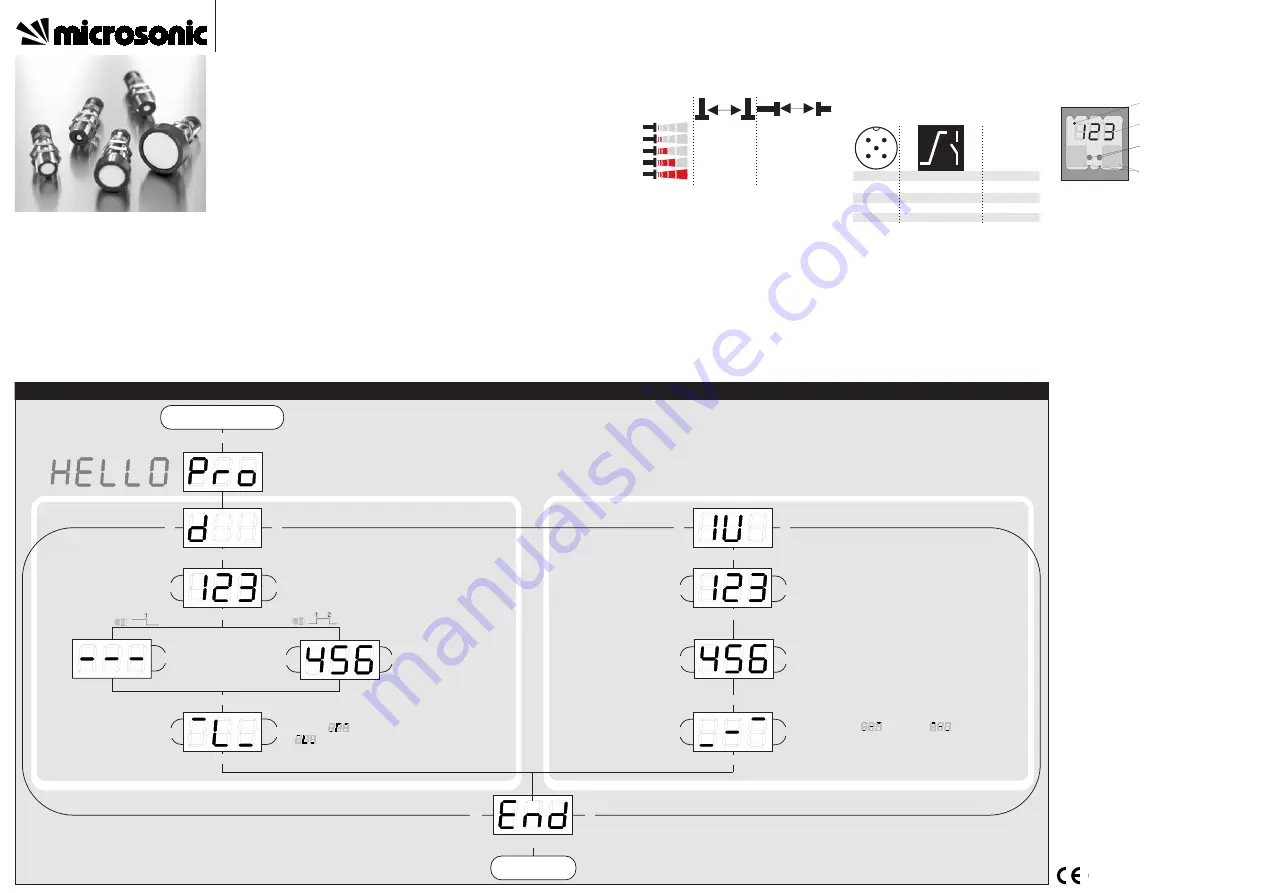

Set detect distance in

mm or cm

For single detect

point press T2

until »- - -« is

displayed

Choose »

« for NCC or

»

« for NOC

T1

T2

For window mode

operation set far

detect point in

mm or cm

T1 + T2

Press T1 and T2 simultaneously for about

3 s until welcome message has passed

T1 + T2

T2

T1

T1 + T2

T1 + T2

T1 + T2

T2

T1

T2

T1

T2

T1

T1 + T2

Set sensor-close window

margin in mm or cm

Choose rising (

) / falling (

)

output characteritic curve

T1

T2

T1 + T2

T2

T1

T1 + T2

T1 + T2

Set switched output

Set analogue output

Set sensor-distant window

margin in mm or cm

Ready

Start here

Set sensor parameters alternatively numerically using LED-display...

Product description

The mic+sensor with one analogue out-

put and one switched output measures

the distance to an object within the de-

tection zone contactless. A signal propor-

tional to distance is created and the

switched output is set according to the

adjusted detect distance.

The sensor automatically detects the load

put to the analogue output and switches

to current output or voltage output re-

spectively.

All settings are done with two push-but-

tons and a three-digit LED-display

(TouchControl).

Light emitting diodes (three-colour LEDs)

indicate all operation conditions.

Choosing between rising and falling out-

put characteristic as well as output func-

tion NOC and NCC is possible.

The sensors are adjustable manually using

the numerical LED-display or may be trai-

ned using Teach-in processes.

Useful additional functions are set in the

Add-on-menu.

Using the LinkControl adapter (optional

accessory) all TouchControl and additio-

nal sensor parameter settings may be

made by a Windows-Software.

Important instructions for assembly and

application

All employee and plant safety-relevant

measures must be taken prior to assembly,

start-up, or maintenance work (see operation

manual for the entire plant and the operator

instruction of the plant).

The sensors are not considered as safety

equipment and may not be used to ensure

human or machine safety!

The mic+sensors indicate a

blind zone

, in

which the distance cannot be measured. The

operating range

indicates the distance of the

sensor that can be applied with normal re-

flectors with sufficient function reserve.

When using good reflectors, such as a calm

water surface, the sensor can also be used up

to its

maximum range

. Objects that strongly

absorb (e.g. plastic foam) or diffusely reflect

sound (e.g. pebble stones) can also reduce

the defined operating range.

Synchronisation

If the assembly distances shown in Fig.1 for

two or more sensors are exceeded the inte-

grated synchronisation should be used. Con-

nect Sync/Com-channels (pin 5 at the units re-

ceptable) of all sensors (10 maximum).

Fig. 1:

Assembly distances, indicating syn-

chronisation/multiplex

Multiplex mode

The Add-on-menu allows to assign an indivi-

dual address »01« to »10« to each sensor

connected via the Sync/Com-channel (Pin5).

The sensors perform the ultrasonic measure-

ment sequentially from low to high address.

Therefore any influence between the sensors

is rejected.

The address »00« is reserved to synchronisa-

tion mode and deactivates the multiplex

<10 cm

<30 cm

<1,0 m

<1,7 m

<60 cm

<1,6 m

<5,4 m

<16 m

<2,6 m

<30 m

A

B

mode. (To use synchronised mode all sensors

must be set to address »00«.)

Assembly instructions

Assemble the sensor at the installation lo-

cation.

Plug in the connector cable to the M 12

connector.

Fig. 2:

Pin assignment with view onto sensor

plug and colour coding of the

microsonic connection cable

Start-up

mic+ sensors are delivered factory made with

the following settings:

Rising analogue characteristic

Window margins for the analogue output

set to blind zone and operating range

Switched output on NOC

1

3

colour

+U

B

-U

B

brown

blue

4

2

5

D

I/U

black

white

Sync/Com.

grey

1

5

2

3

4

Detecting distance at operating range

Measurement range set to maximum range

Set the parameters of the sensor manually or

use the Teach-in procedure to adjust the de-

tect points.

Fig. 3: TouchControl

Operation

mic+sensors work maintenance free. Small

amounts of dirt on the surface do not influ-

ence function. Thick layers of dirt and caked-

on dirt affect sensor function and therefore

must be removed.

Note

mic+sensors have internal temperature

compensation. Because the sensors heat

up on their own, the temperature com-

pensation reaches its optimum working

point after approx. 30 minutes of opera-

tion.

If an object is within the set window mar-

gins of the analogue output, then LED D1

lights up green, if the object is outsite the

window margins, then LED D1 lights up

red.

The load put to the analogue output is

detected automatically when turning

supply voltage on.

During normal mode operation, a yellow

LED D2 signals that the switched output

has connected.

During normal mode operation, the mea-

sured distance value is displayed on the

LED-indicator in mm (up to 999 mm) or

cm (from 100 cm). Scale switches auto-

matically and is indicated by a point on

top of the digits. Alternatively a percent-

age scale may be set in the add-on menu.

In this connection 0% and 100% corre-

spond to the set window margins of the

analogue output.

In the »Two-way reflective barrier« ope-

rating mode, the object has to be within

the range of 0-85 % of the set distance.

During Teach-in mode, the hysteresis

loops are set back to factory settings.

If no objects are placed within the detec-

tion zone the LED-indicator shows »- - -«.

If no push-buttons are pressed for 20 se-

conds during parameter setting mode the

made changes are stored and the sensor

returns to normal mode operation.

Show parameters

Tapping push-button T1 shortly during nor-

mal mode operation shows »PAr« on the

LED-display. Each time you tap push-button

T1 the actual settings of the analogue output

and the switched output are shown.

Instruction manual

mic+ Ultrasonic Sensors with

one analogue output and one

switched output

c

m

m

m

%

T

1

D

1

D 2 T 2

measuring range

LED D1 and D2

3-digit

LED-display

Push-buttons T1 and T2

mic+25/DIU/TC

mic+35/DIU/TC

mic+130/DIU/TC

mic+340/DIU/TC

mic+600/DIU/TC

2004/108/EC