13

2.

Operation

Turn ON/OFF switch is at the rear side of the equipment. FORCIPOL units have quite simple

operation. ON / OFF and WATER buttons are placed on the front plate. (Fig. 3)

FORCIPOL 1V, FORCIPOL 2V, FORCIPOL 300-1V,

Variable speed FORCIPOL units have Digital display and setting buttons on the front plate. The

overload protection on the motor is managed by the speed controller. PC-board will shut off the

power to the motor and after a short period, the instrument will be ready for operation again

automatically. The rotational direction of the wheel can be selected as CW or CCW from the front

panel.

3.

Time Setting

For setting time press (*) botton while the STOP button is active.

Select STT module.

After that press PROGRAM button to see time adjusting mode.

Adjust the required time by means of (ˆ)UP and (ˇ) DOWN buttons.

Save the changes by pressing PROGRAM button and use * button to get out the

programming mode.

E.

SERVICE and MAINTENANCE

1.

MAINTENANCE

1.1

Daily Maintenance

Clean all accessible surfaces with a moist cloth.

When using embedding resins, aluminium oxide polishing, etc., the machine should be

throughly cleaned to prevent resin or oxide to block the outlet hose or the drain hole in the

bowl.

Clean the bottom side of the PVC or Aluminium disc by a wet cloth to remove the particles,

residual material etc. as shown in Fig.4.

At the end of the working day, clean the bowl with water.

Fig.4.Cleaning of the Platen

Содержание FORCIPOL 1V

Страница 1: ...OPERATINGandINSTRUCTIONSMANUAL FORCIPOL GRINDING POLISHINGSYSTEM ...

Страница 2: ......

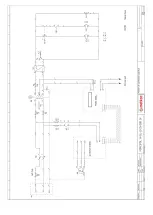

Страница 23: ...23 3 Electrical Wiring Diagrams ...

Страница 24: ......

Страница 25: ......

Страница 26: ......

Страница 27: ......

Страница 28: ......