29

13.8

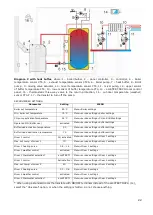

Connection of temperature sensors

Sensor wires may be extended using wires of

cross-section area not less than 0.5 mm

2

.

Total length of wires of each sensor should

not exceed 15 m.

Insert boiler temperature sensor into

thermometer well fastened to boiler shell.

Fasten feeder temperature sensor to the

surface of feeder screw tube. Insert

temperature sensor of HUW container into

thermometer well welded to the container.

The best way to mount mixer temperature

sensor is to insert it into a sleeve located in

the stream of flowing water, however, it is

also allowed to fasten the sensor in a contact

manner provided that the sensor and the

pipe are properly heat-insulated.

Sensors shall be protected against

loosening from surfaces they are

mounted to.

Make sure thermal contact between the

sensors and the surface which temperature is

measured is good. Apply thermal paste to

improve the contact. Pouring sensors with oil

or water is not allowed. Sensor wires should

be separated from power supply wires.

Otherwise, temperature indications may be

erroneous. Min. distance between these

wires should be 10 cm.

Do not allow sensor wires to contact hot

parts of the boiler and heating system. Wires

of temperature sensors are heat resistant to

the temperature not exceeding 100°C.

13.9

Connecting weather sensor

The regulator cooperates only with a weather

sensor of the CT6-P type. The sensor should

be installed on the coldest wall of the

building, usually this is the northern wall,

under a roof. The sensor should not be

exposed to direct sunlight and rain. The

sensor should be fitted at least 2 m above

the ground, far from windows, chimneys and

other heat sources which could disturb the

temperature measurement (at least 1,5 m).

Connect the sensor using cable of 0,5 mm

2

cross-section, up to 25 m long. Polarity of

the leads is insignificant. Connect the other

end of the cable to the regulator.

Attach the sensor to the wall using tackbolts.

To access the tackbolts holes, unscrew the

sensor lid.

13.10

Checking temperature sensors

The temperature sensor can be checked by

measuring its resistance in a given

temperature. Replace the sensor if there are

significant differences between the measured

resistance and the values provided in the

table below.

CT4

Ambient temp.

°C

Min.

Ω

Rated

Ω

Max.

Ω

0

802

815

828

10

874

886

898

20

950

961

972

25

990

1000

1010

30

1029

1040

1051

40

1108

1122

1136

50

1192

1209

1225

60

1278

1299

1319

70

1369

1392

1416

80

1462

1490

1518

90

1559

1591

1623

100

1659

1696

1733

exhaust CT2S-2, CT6-P

Temp.

°C

Min.

Ω

Rated

Ω

Max.

Ω

0

999.7

1000.0

1000.3

25

1096.9

1097.3

1097.7

50

1193.4

1194.0

1194.6

100

1384.2

1385.0

1385.8

125

1478.5

1479.4

1480.3

150

1572.0

1573.1

1574.2

Содержание ecoMAX860P2-T

Страница 2: ...2...

Страница 6: ......

Страница 7: ...REGULATOR INSTRUCTION MANUAL ecoMAX860P2 T...

Страница 19: ...19 CONTROLLER INSTALLATION AND SERVICE SETTINGS MANUAL ecoMAX860P2 T...

Страница 43: ......

Страница 44: ......

Страница 45: ......

Страница 46: ......

Страница 47: ......

Страница 48: ...Jacek Kucharewicz ul Sikorskiego 66 16 100 Sok ka Poland tel 48 85 711 94 54 www metalfachtg com pl...