12

information about lack thereof is displayed in

the main window. The parameter:

Menu

→

HUW settings

→

HUW pump

mode

allows the user to:

disable

filling

of

the

tank,

parameter

off,

set HUW priority, using the

priority

parameter - in this case, the CH pump is

deactivated to speed up filling of the

HUW tank.

set simultaneous operation of the CH and

HUW pump, using parameter

no priority

,

The regulator has a function of automatic,

periodic heating of HUW container to 70 °C

to eliminate bacterial flora from the HUW

container.

Keep the tenants informed of

activating the disinfection function

as there is risk of being burnt with

hot usable water.

The regulator increases the HUW container

temperature once a week, at 2:00 a.m.

Monday. After 10 minutes of maintaining the

temperature at 70 °C, the HUW pump is

switched off and the boiler returns to normal

operation. Do not activate the disinfection

function when the HUW support is off.

8.11

Setting HUW preset temperature

Preset HUW temperature is defined by

parameter:

HUW settings

→

HUW preset temp.

HUW tank hysteresis

When the temperature drops below the HUW

set temperature – HUW tank hysteresis, the

HUW pump will start in order to supply the

HUW tank.

In low hysteresis values, the HUW

pump will start faster when the

HUW temperature drops.

8.12

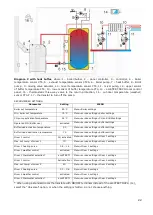

HUW Circulation

The settings are located in:

HUW Settings

→

Circulation pump night

time decrease

and

Service Settings

→

CH and HUW settings

The time settings of the circulation pump are

analogous to the settings of night time

decrease. The pump will be off in the defined

time periods. At other times, the pump will

be on at

Circulation pump working time

between every

Circulation pump stand-by

time

.

8.13

Enabling the Summer function

To enable the SUMMER function, heating the

WUH tank without the need of supplying the

CH installation, set the

Summer mode

parameter to on.

Menu

Summer mode

In Summer mode, all heat

receivers may be shut off, so

before enabling it please make

sure that the boler does not

overheat.

If the weather sensor is connected, switching

between SUMMER and WINTER mode may

occur automatically.

8.14

Mixer circuits settings

Settings for the first mixer circuit can be

found in the menu:

Menu

→

Mixer 1 settings

Settings for other mixers can be accessed in

next menu items and they are identical for

each circuit.

Settings for mixer

(without weather

sensor)

It is necessary to manually set the required

water temperature in the heating mixer

circuit using parameter

Preset mixer temp.

,

e.g. at a value of 50°C. The value should

allow

to

obtain

the

required

room

temperature.

After connecting room thermostat, it is

necessary to set a value of decrease in

preset mixer temperature by thermostat

(parameters

Mixer room therm.)

e.g. at 5°C.

This value should be selected by trial and

error. The room thermostat can be a

traditional thermostat (no/nc), or room panel

ecoSTER TOUCH. Upon activation of the

thermostat,

the

preset

mixer

circuit

Содержание ecoMAX860P2-T

Страница 2: ...2...

Страница 6: ......

Страница 7: ...REGULATOR INSTRUCTION MANUAL ecoMAX860P2 T...

Страница 19: ...19 CONTROLLER INSTALLATION AND SERVICE SETTINGS MANUAL ecoMAX860P2 T...

Страница 43: ......

Страница 44: ......

Страница 45: ......

Страница 46: ......

Страница 47: ......

Страница 48: ...Jacek Kucharewicz ul Sikorskiego 66 16 100 Sok ka Poland tel 48 85 711 94 54 www metalfachtg com pl...