Form 43343350

Dec 2017

-61-

1.

Open hinged access panel.

2.

Add tubing to connect the air switch tubing P1 + and P2 - with the connector tees and the probes P1+ and

P2+.

3.

Connect plastic tubing of a digital or inclined water manometer with a 0-2” scale onto the connector tees.

4.

Turn heater on and wait until blower motor is activated.

5.

Observe air pressure from manometer. This should be higher than the set point indicated below for correct

operation.

Model

Operating Pressure

R(B,S,M) S/U 040

0.98” W.C. Hot

R(B,S,M) S/U 050

0.98” W.C. Hot

R(B,S,M) S/U 075

0.70” W.C. Hot

R(B,S,M) S/U 100

0.70” W.C. Hot

R(B,S,M) S/U 125

0.39” W.C. Hot

R(B,S,M) S/U 150

0.39” W.C. Hot

R(B,S,M) S/U 175

0.39” W.C. Hot

R(B,S,M) S/U 200

0.39” W.C. Hot

All pressures are with the heater in operation for at least 15 minutes.

23.4)

IGNITION SYSTEM CHECKS

TO CHECK FLAME SENSOR CIRCUIT.

Flame current is the current which passes through the flame from the sensor to ground. The minimum flame

current necessary to keep the system from lockout is 0.7 microamps.

a.

Turn off heater at thermostat.

b.

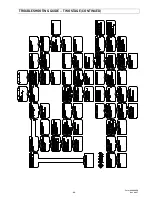

Connect a meter (dc microammeter scale) in series with the ground lead as shown in the diagram. Connect

the meter as follows:

Connect the black (negative) meter lead to the electronic control FC- terminal.

Connect the red (positive) meter lead to the electronic control FC+ terminal.

c.

Restart the system and read the meter. The flame sensor current must be steady and measure at least 0.7

microamps.

d.

If the meter reads less than the minimum or if reading is unsteady:

Make sure burner flame is capable of providing a good rectification signal.

Make sure fasteners securing igniter/sensor are tightened to assure correct positions. DO NOT relocate

igniter/sensor.

Check for excessive (over 1000ºF) temperature at ceramic insulator on flame sensor. Excessive

temperature can cause short to ground. DO NOT relocate igniter/sensor.

Check for cracked ceramic insulator, which can cause short to ground, and replace sensor if necessary.

Make sure that electrical connections are clean and tight. Replace damaged wire.

e.

If the meter reads below “0” on the scale, meter leads are reversed. Disconnect power and reconnect meter

leads for proper polarity.

f.

Remove microammeter. Return system to normal operation.

Содержание 44488010

Страница 15: ...Form 43343350 14 Dec 2017 7 1 TYPICAL ASSEMBLY LAYOUT STRAIGHT SERIES SHOWN ...

Страница 16: ...Form 43343350 Dec 2017 15 8 0 DIMENSIONS STRAIGHT SERIES Typical Dimensions Up to 60 Ft Shown ...

Страница 17: ...Form 43343350 16 Dec 2017 8 1 DIMENSIONS U SERIES Typical Dimensions Up to 50 Ft Shown ...

Страница 18: ...Form 43343350 Dec 2017 17 8 2 HEATER ASSEMBLY JOINING OF TUBE SECTIONS ...

Страница 19: ...Form 43343350 18 Dec 2017 ...

Страница 52: ...Form 43343350 Dec 2017 51 20 0 CONTROL COMPONENT LOCATION ...

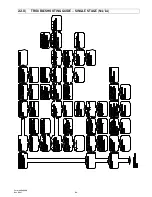

Страница 54: ...Form 43343350 Dec 2017 53 22 0 TROUBLESHOOTING GUIDE SINGLE STAGE N1 L1 ...

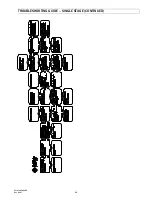

Страница 55: ...Form 43343350 54 Dec 2017 TROUBLESHOOTING GUIDE SINGLE STAGE CONTINUED ...

Страница 56: ...Form 43343350 Dec 2017 55 TROUBLESHOOTING GUIDE SINGLE STAGE CONTINUED ...

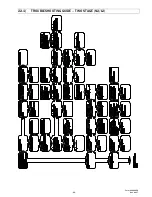

Страница 57: ...Form 43343350 56 Dec 2017 22 1 TROUBLESHOOTING GUIDE TWO STAGE N2 L2 ...

Страница 58: ...Form 43343350 Dec 2017 57 TROUBLESHOOTING GUIDE TWO STAGE CONTINUED ...

Страница 59: ...Form 43343350 58 Dec 2017 TROUBLESHOOTING GUIDE TWO STAGE CONTINUED ...

Страница 61: ...Form 43343350 60 Dec 2017 23 2 REMOVING GAS VALVE AND MANIFOLD ASSEMBLY 23 3 AIR SWITCH PRESSURE CHECK ...

Страница 66: ...Form 43343350 Dec 2017 65 ...