MERCARB 2 BARREL CARBURETOR

SERVICE MANUAL NUMBER 24

Page 5B-28

90-861327--1 OCTOBER 1999

Cleaning and Inspection

IMPORTANT: DO NOT use a wire or drill to clean jet passages or tubes in carburetor,

as this may enlarge orifices and seriously affect carburetor calibration.

CAUTION

To avoid damage to carburetor DO NOT leave carburetor in immersion type carbure-

tor cleaner for more than two hours.

IMPORTANT: DO NOT clean float bowl gasket surfaces with a gasket scraper or knife,

as sealing bead will be damaged and float bowl replacement will be necessary.

CAUTION

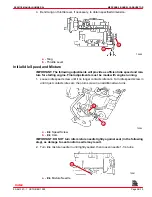

The float assembly, float needle, accelerator pump plunger, and fuel filter MUST

NOT BE immersed in carburetor cleaner, as they will swell, harden, and/or distort.

72410

a

b

c

d

a -

Accelerator Pump Plunger

b -

Float Needle

c -

Fuel Filter

d -

Float Assembly

WARNING

Avoid personal injury by always wearing safety goggles when using compressed

air.

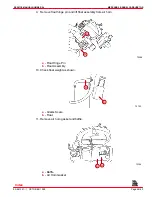

1. Clean all metal parts in a commercial carburetor cleaner until all deposits have been re-

moved. Follow cleaner manufacturer’s instructions for proper cleaning and rinsing pro-

cedure. Dry parts with compressed air.

2. Using compressed air, blow out all passages in carburetor to remove any foreign

material.

3. Wipe off all parts that cannot be cleaned in carburetor cleaner with a clean, dry cloth.

4. Carefully inspect all carburetor parts for wear and damage. Pay particular attention to

the following:

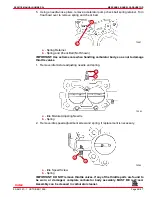

a. Float Needle and Seat: If float needle or seat is worn or damaged, replace with new

needle and seat assembly.

IMPORTANT: Float needle and seat are factory matched and tested and should be

replaced as a set only.

b. Float Assembly and Hinge Pin: Check float density (to see if it is saturated with

fuel) by comparing weight of float with specifications. If weight is high, float assembly

must be replaced. Check hinge pin and holes for wear.

c. Fuel and Air Passages: Passages must be perfectly clean for proper carburetor

operation.

Index

Содержание 305 CID (5.0L)

Страница 116: ...TROUBLESHOOTING SERVICE MANUAL NUMBER 24 Page 1C 34 90 861327 1 OCTOBER 1999 THIS PAGE IS INTENTIONALLY BLANK Index ...

Страница 142: ...MCM MODELS SERVICE MANUAL NUMBER 24 Page 2A 26 90 861327 1 OCTOBER 1999 THIS PAGE IS INTENTIONALLY BLANK Index ...

Страница 166: ...MIE MODELS SERVICE MANUAL NUMBER 24 Page 2B 24 90 861327 1 OCTOBER 1999 THIS PAGE IS INTENTIONALLY BLANK Index ...

Страница 285: ...STARTING SYSTEM SERVICE MANUAL NUMBER 24 Page 4A 30 90 861327 1 OCTOBER 1999 THIS PAGE IS INTENTIONALLY BLANK Index ...

Страница 315: ...IGNITION SYSTEM SERVICE MANUAL NUMBER 24 Page 4B 30 90 861327 1 OCTOBER 1999 THIS PAGE IS INTENTIONALLY BLANK Index ...

Страница 344: ...CHARGING SYSTEM SERVICE MANUAL NUMBER 24 90 861327 1 OCTOBER 1999 Page 4C 29 THIS PAGE IS INTENTIONALLY BLANK Index ...

Страница 345: ...CHARGING SYSTEM SERVICE MANUAL NUMBER 24 Page 4C 30 90 861327 1 OCTOBER 1999 THIS PAGE IS INTENTIONALLY BLANK Index ...

Страница 364: ...INSTRUMENTATION SERVICE MANUAL NUMBER 24 90 861327 1 OCTOBER 1999 Page 4D 19 THIS PAGE IS INTENTIONALLY BLANK Index ...

Страница 365: ...INSTRUMENTATION SERVICE MANUAL NUMBER 24 Page 4D 20 90 861327 1 OCTOBER 1999 THIS PAGE IS INTENTIONALLY BLANK Index ...

Страница 383: ...MAINTENANCE SERVICE MANUAL NUMBER Page 4E 18 90 861327 1 OCTOBER 1999 THIS PAGE IS INTENTIONALLY BLANK Index ...

Страница 721: ...DIAGNOSTICS SERVICE MANUAL NUMBER 24 Page 5G 94 90 861327 1 OCTOBER 1999 THIS PAGE IS INTENTIONALLY BLANK Index ...

Страница 779: ...GENERAL SERVICE MANUAL NUMBER 24 Page 7A 6 90 861327 1 OCTOBER 1999 THIS PAGE IS INTENTIONALLY BLANK Index ...

Страница 803: ...COLLECTORS SERVICE MANUAL NUMBER 23 Page 7C 16 90 861327 1 OCTOBER 1999 THIS PAGE IS INTENTIONALLY BLANK Index ...

Страница 859: ...HURTH TRANSMISSIONS SERVICE MANUAL NUMBER 24 Page 8C 18 90 861327 1 OCTOBER 1999 THIS PAGE IS INTENTIONALLY BLANK Index ...