MCR

P

ROSMOKE

FS

O

PERATION AND

M

AINTENANCE

M

ANUAL

Page 7 of 20

5. TRANSPORT AND DELIVERY

Curtains are generally supplied pre-assembled. Unloading must be carried out under

the supervision of a person authorised by the manufacturer, using generally available means

of handling (e.g. forklift trucks, cranes equipped with spreader boom slings) or manually,

paying special attention to the protection of curtains against damage.

6. INSTALLATION OF CURTAINS

Do not disassemble and do not disconnect the MECU XL motor control system

from the motor.

Each curtain model requires a 230 V supply voltage.

Curtains should be installed in civil structures in accordance with their

respective construction designs, in order to ensure the design gap sizes.

Curtains should be fixed under the ceiling, to lintels, prepared structures or other

building features intended for this purpose as per the construction design. The structural

component should be made of concrete or steel. When designing the structural component,

the device weight should be taken into account: approx. 200 ÷ 300 N/lm, depending on the

curtain height. For curtains without brackets, the mounting surface should be vertical or

horizontal, with a flatness deviation of up to 5 mm along the curtain length.

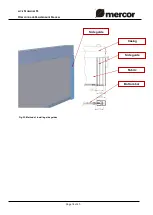

Curtains mounted on suspension brackets of more than 0.5 m in length should be

strengthened by attaching the casing e.g. to a reinforced concrete wall, a girder, etc. As to

multi-modular casings, they should be fastened together as shown in fig. 9 by means of self-

drilling screws or rivets not longer than 20 mm, so that uncontrolled movements of casings

relative to each other are eliminated.

Curtain installation should be carried out as follows:

Curtains with brackets:

1. Mount M10 or M12 threaded rods of suitable length in the structural component to

match the arrangement of brackets

(fig. 7)

.

To mount the threaded rods, use fasteners suitable for the structural component

material (e.g. HK8 HILTI anchors).

2. Screw M10 or M12 nuts onto the rods.

3. Hang the curtain on the rods using a M10 or M12 rough finish washer and a nut with

protection cap.

4. Using the nuts, adjust the horizontal position of the curtain casing.

5. Tighten the nuts driven according to item 2, check if the fastenings are secure.

6. Connect the free terminals of MECU XL

(fig. 12)

to the control device, i.e. the mcr

9705 or mcr 0204 control unit, and to the 230 V power supply. Observe polarity (+ to

+, - to -). The mcr 9507 control unit should be set to the door control mode or the mcr

0204 control unit should be set to the curtain control mode.

7. Install the side guides, if ordered, using steel fasteners.

8. Make sure that there are no obstacles under the curtain and check if the curtain rolls

out to the desired height and rolls up properly. Adjust the length of the fabric feed, if

required (see: Limit switch adjustment

– page 9).

9. Check the system operation by triggering the alarm from all available sources.

Curtains without brackets:

1. Unscrew the access cover.

2. Remove the roller with fabric, i.e.:

a. Remove the pin locking the motor.

b. Unscrew the four screws securing the plate protecting the drive.