- 7 -

SERVICE

Assembly and disassembly should be performed by a

service technician who has been factory trained on MBW

equipment. The unit should be clean and free of debris.

Pressure washing before disassembly is recommended.

• Prior to assembly, wash all parts in a suitable cleaner or

solvent.

• Check moving parts for wear and failure. Refer to the

Replacement section in this manual for tolerance and

replacement cycles.

• All seals and bearings should be oiled prior to assembly.

Also, ensure that the seals are inserted square and are

seated properly.

• Leaking air caused by worn seals will decrease

performance of Ergo-Tamp.

General

The disassembly and assembly procedures given here are

intended for a complete dismantling of the MBW Ergo-

Tamp. Read the following sections carefully.

Handle and Tamper Separation

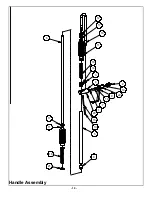

Refer to Handle Assembly, page 10.

1.

Remove the bottom zip tie (#17) from the bellows

(#11)

2.

Loosen jam nut (#21) from tamper cap and unscrew

Tamper Assembly from Handle Assembly.

Handle Disassembly

Refer to Handle Assembly, page 10.

3.

Detach the hose (#16) from cap (#12) and fitting (#3).

4.

Remove the zip ties (#17) from both bellows (#11).

5.

Unscrew the jam nut (#21) from the handle.

6.

Slide inner shaft (#6) up out of outer tube (#5).

7.

Slide bellows (#11) and springs (#18) off.

8.

Remove coupler (#2) from valve body. Don’t loose

the spring (#19)

9.

Remove the two screws (#22) from the hand guard

(#9) and slide guard off of handle.

10. Unthread lower and upper bushing (#8, #14). (Note:

Due to thread locking compound used in assembly

heat might be need to help loosen bushings.)

11. Slide valve body assembly (#4) off of outer tube (#5).

12. Using a 10-32 bolt, pull the spool (#7) out of the valve

body (#4), then separate the o-ring (#10) and valve

seal (#1).

Handle Assembly

Refer to Handle Assembly, page 10.

1.

Lubricate new o-ring (#10) with air tool oil and then

place on spool (#7).

2.

Lubricate valve seal (#1) and spool (#7) and insert in

valve body (#4).

3.

Slide valve body (#4) onto outer tube (#5).

4.

Using medium-strength thread locking compound,

screw lower bushing (#8) and upper bushing (#14)

(through valve body (#4)) to outer tube (#5).

5.

Slide hand guard (#9) into position and secure with

the two bolts (#22).

6.

Insert conical spring (#19), narrow end first, into valve

body, then screw coupler (#2) in. Use pipe sealing

compound on threads of coupler.

7.

Grease inner shaft (#6) and slide into outer tube (#5).

The end with the longer threads needs to be towards

the bottom of the handle.

8.

Slide the springs (#18) onto the inner shaft (#6) and

then cover springs with bellows (#11).

9.

Secure top spring (#18) with cap (#12) and bottom

spring (#18) with jam nut (#21).

10. Seat two zip ties (#17) to both bellows (#11). (Note:

Position zip ties to fit into grooves of parts ).

11. Attach hose (#16) to fitting (#3) and cap (#12).

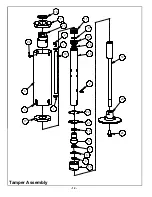

Tamper Disassembly

Refer to Tamper Assembly, page 12.

1.

Remove bolt (#24) and tap the tamper foot (#23) off

from shaft (#14).

2.

Remove retaining ring (#22), lift locking ring (#21)

and remove cap (#15).

3.

Remove shim (#5) and wiper (#3) from bottom cap

(#15).

4.

Slide bushing support (#8) out of body (#10) and

remove seal set (#4) and o-ring (#16).

5.

Grasp shaft (#14) and remove from body (#10).

6.

Take out the four screws (#20) from the top shroud

cover (#7).

7.

While holding the outer shroud (#6) push the body

(#10) into the shroud.

Содержание ERGO-TAMP

Страница 13: ...10 Handle Assembly...

Страница 15: ...12 Tamper Assembly...