7

3. TECHNICAL CHARACTERISTICS

3.1.

Machine Description

The double rotary float machine model MK8 90

has been designed and constructed to float

concrete and bituminous floors of warehouses,

car parks, cycle tracks, parking areas, pavements,

etc. For this purpose the machine is equipped with

two rotors, one turning clockwise and the other

counter-clockwise.

Both the engin

e and the operator’s seat are fixed

to a frame connected to both rotors.

The very low position of the seat has the following

advantages:

Superior planarity of the floor surface (as a

result of lowering of the machine

’s center of

gravity)

Perfect vision

The seat can be adjusted to the most comfortable

driving position for the operator. All the steering

components, joysticks, joints, drive shaft and

reduction gears are protected by a tunnel to

prevent cement encrustations from accumulating

over time, which could lead to more rapid wear of

the mechanical components.

3.2.

Technical Data and Details

Description

Unit

of

meas

ure

Cod 3325

Cod 3326

Cod 3328

Cod 3335

Cod 3341

Cod 3342

Dimensions:

[mm]

2050x1030x10

40

2050x1030x10

40

2050x1030x10

40

2050x1030x10

40

2050x1030x10

40

2050x1030x10

40

Packaging dimensions

[mm]

2170x1080x10

00

2170x1080x10

00

2170x1080x10

00

2170x1080x10

00

2170x1080x10

00

2170x1080x10

00

Operating weight

[kg ]

360

368

374

360

372

376

Shipping weight

[kg ]

358

360

362

390

390

390

Motorization:

-

Kohler

Kohler

Kohler

Honda

B&S

B&S

Power installed:

[HP]

23,5

25

32,5

24

31

35

Starting:

-

Electric

Electric

Electric

Electric

Electric

Electric

Cooling:

-

Air

Air

Air

Air

Air

Air

Fuel:

-

Gasoline

Gasoline

Gasoline

Gasoline

GAsoline

Gasoline

Fuel tank capacity:

l

11

11

11

11

11

11

Max engine rotation speed:

[rpm]

3600

3600

3600

3600

3600

3600

Min - max blade rotation

speed:

[rpm]

70-125

70-125

70-125

70-125

70-125

70-125

Rotor diameter:

[mm]

900

900

900

900

900

900

Number of blades:

-

8

8

8

8

8

8

Max. forward speed

[m/min

]

90

90

90

90

90

90

Acoustic pressure level:

[dB]

93.2

93.2

93.2

93.2

93.2

93.2

Acoustic pressure level at

driver’s seat:

[dB]

97.10

97.10

97.10

97.10

97.10

97.10

Acoustic power level:

[dB]

109.4

109.4

109.4

109.4

109.4

109.4

Quadratic mean value of

acceleration:

m/s

2

0,8 - 1

0,8 - 1

0,8 - 1

0,8 - 1

0,8 - 1

0,8 - 1

(1)

Measured with petrol-powered engine

Содержание 1830041

Страница 3: ...3...

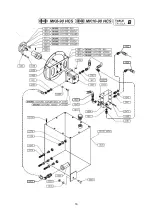

Страница 14: ...14 7 11 Parts List...

Страница 15: ...15...

Страница 16: ...16...

Страница 17: ...17...

Страница 18: ...18...

Страница 19: ...19...

Страница 20: ...20...

Страница 21: ...21...

Страница 22: ...22...

Страница 23: ...23...

Страница 24: ...24...

Страница 25: ...25...

Страница 26: ...26...

Страница 27: ...27...

Страница 28: ...28...

Страница 29: ...29...

Страница 30: ...30...

Страница 31: ...31...

Страница 32: ...32...

Страница 33: ...33...

Страница 34: ...34...

Страница 35: ...35...

Страница 36: ...36...

Страница 37: ...37...

Страница 38: ...38...

Страница 39: ...39...

Страница 40: ...40...

Страница 41: ...41...

Страница 42: ...42...

Страница 43: ...43...

Страница 44: ...44...

Страница 45: ...45...

Страница 46: ...46...

Страница 47: ...47...

Страница 48: ...48...

Страница 49: ...49...

Страница 50: ...50...

Страница 51: ...51...

Страница 52: ...52...

Страница 55: ...55 NOTES...