53

7.12.

Troubleshooting

FAULT

PROBABLE CAUSE

REMEDY

The float machine leaks

oil

Too much oil in gear reduction

Unscrew the cap

The screws of the reduction gear

covers are loose

Tighten the screws

Defective gaskets

Contact our technical service

Oil seal on central and side shaft worn Contact our technical service

Oil leaks from engine

Contact our technical service

The engine does not start

No fuel

Fill the tank with the fuel indicated for

the engine used

Fuel cock closed

Open the fuel cock

(

)

Fuel filter clogged

Replace the filter

(

)

Choke fully open

Close the choke

(

)

Air filter dirty

Clean the air filter

(

)

No spark

Clean the spark plug and replace it if

necessary

(

)

Check the plug connection

(

)

Ignition difficulty, engine flooded

Unscrew the spark plug and dry it

(

)

Battery flat

Recharge or replace the battery (Par.

7.3)

Emergency stop on

Turn emergency stop off

Drop in engine rpm

Accelerator cable broken or bent

Replace the accelerator cable

Engine problems

Contact our technical service

Carburetor dirty

Contact our technical service

Air filter dirty

Clean or replace the air filter

(

)

The float machine does

not move forward and

backward

Tie rod broken

Replace tie rod

Fork pin broken or slipped off

Replace fork pin

Bascule support jammed

Clean bascule support

The float machine does

not steer left or right

Joysticks broken

Replace joysticks

Joystick supports broken

Replace joystick supports

The blades do not lift

Steel cord broken

Replace blade-lifting cord

Steel cord nut lacking

Fit nut

Fork broken

Replace fork

The float machine

bounces on the floor

Cement hardened under spider or

blades

Clean the spider and the blades

Blades not evenly worn

Adjust the blade inclination

Central shaft bent

Contact our technical service

Drive control not perfectly vertical

Adjust the drive control position

Blades maladjusted

Adjust the blades

When the engine is

revved up the rotors do

not turn

Driving belts loose and/or worn

Tighten the driving belts (see Par. 7.7)

or replace them

Clutch lining worn

Replace the lining

(

)

See engine use and maintenance manual

Once the power trowel guarantee has expired, the

machines should be subjected to a complete

check-up once a year. You can address to all our

authorized dealers all around the world.

MBW, Inc. will refuse all responsibility in case of

incident whenever the check-ups are not routinely

conducted.

Содержание 1830041

Страница 3: ...3...

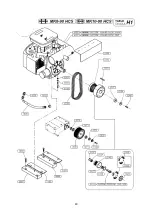

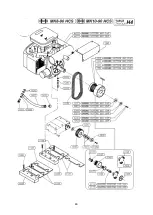

Страница 14: ...14 7 11 Parts List...

Страница 15: ...15...

Страница 16: ...16...

Страница 17: ...17...

Страница 18: ...18...

Страница 19: ...19...

Страница 20: ...20...

Страница 21: ...21...

Страница 22: ...22...

Страница 23: ...23...

Страница 24: ...24...

Страница 25: ...25...

Страница 26: ...26...

Страница 27: ...27...

Страница 28: ...28...

Страница 29: ...29...

Страница 30: ...30...

Страница 31: ...31...

Страница 32: ...32...

Страница 33: ...33...

Страница 34: ...34...

Страница 35: ...35...

Страница 36: ...36...

Страница 37: ...37...

Страница 38: ...38...

Страница 39: ...39...

Страница 40: ...40...

Страница 41: ...41...

Страница 42: ...42...

Страница 43: ...43...

Страница 44: ...44...

Страница 45: ...45...

Страница 46: ...46...

Страница 47: ...47...

Страница 48: ...48...

Страница 49: ...49...

Страница 50: ...50...

Страница 51: ...51...

Страница 52: ...52...

Страница 55: ...55 NOTES...