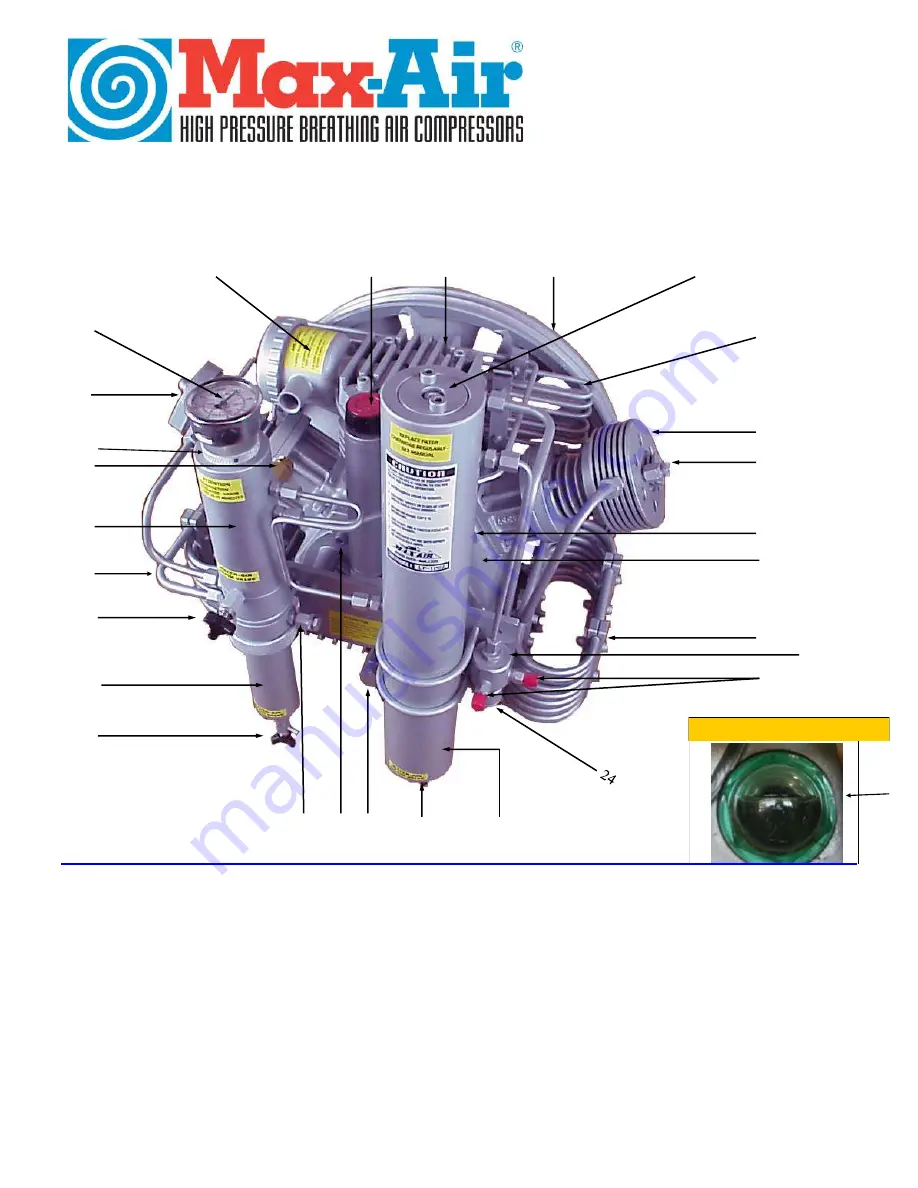

1.

Intake filter housing

15.

Oil and water separator (high pressure)

2.

Valve Head 1st Stage

15.A.

Oil and water separator (low pressure)

3.

Valve Head 2nd Stage

16.

Oil and water separator drain tap, high pressure

4.

Valve Head 3rd Stage

16.A.

Oil and water separator drain tap, low pressure

5.

Interstage cooler I – 2nd stage

17.

Purifier housing

6.

Interstage cooler II – 3rd stage

17.A.

Purifier housing cap

7.

After cooler

18.

Filter housing drain tap

8.

Safety valve 1st stage

19.

Pressure maintaining valve (1800 psi)

9.

Safety valve 2nd stage

20.

Purified air outlets (2)

10.

Crankcase casting

21.

Final safety relief valve (factory preset to customer requirement)

11.

Front bearing cover

22.

Check valve—INSIDE upper separator

12.

Fan wheel

23.

Oil fill vent cap screw

13.

Oil filler

cap

24.

Oil level indicator, behind filter housing (not shown)

See figure 1.

14.

Oil drain plug

25.

Final pressure gauge bar/psi

NOTE: DO NOT RE

-

ADJUST SAFETY VALVES #8, 9 and 21, unless you are a licensed, qualified high

pressure compressor mechanic (CALL THE FACTORY)!

Rev. Date 6.3.16

Pg 3

Form MA90Blk

-

IS004/09

1

16A

2

5

3

8

12

6

23

15

17

11

4

20

16

10

14

19

18

17A

25

2807 Peddler Lane

Kerrville Texas 78028

Ph. 830

-

257

-

5006 Fax. 830

-

257

-

3720

service @max

-

air.com

www.max

-

air.com

7

Figure 1. Oil Level Sight Glass

9

13

22

Compressor Pumping Group Identification Sheet

Model Max

-

Air 55, 90 and 180 Twin

21

INSIDE

15A

Page 13 of 22