8

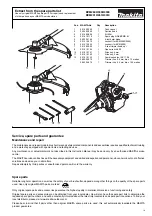

Shown: BCM2600

Type plate

(BCM2600)

Indicate when ordering spare parts!

Serial number

Year of manufacture

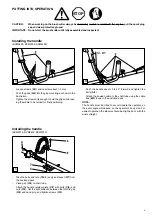

Components

1

Cutting tool

2

Gear box

3

Guard (Cutter guard)

4

Shaft tube

5

Handle

6

Throttle (throttle trigger)

7

Combination “start/stop” (O/I) switch, half-throttle lock

8

Safety locking button (throttle trigger lockout)

9

Bowden cable guide

10

Tube handle holder

11

Stop knob for halfway throttle

12

Harness eyelet (suspension point)

13

Fuel tank cap

14

Spark plug cover

15

Starter grip

16

Type plate

17

Choke lever

18

Harness

2310 | 2610 | 3310

2600 | 3300 | 4300

BCM2600

2008 123456

22045 Hamburg

Germany

000.000.000

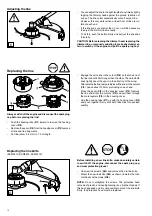

Technical Data

Displacement cm

3

22.6 | 25.6 | 32.6

25.6 | 32.6 | 42.7

Bore

mm

31 | 33 | 36

33 | 36 | 40

Stroke

mm

30 | 30 | 32

30 | 32 | 34

Rated capacity per ISO 8893

kW

0.7 | 0.8 | 0.97

0.8 | 0.97 | 1.27

Operating speed

rpm

8,000 | 8,000 | 7,500 8,000 | 7,500 | 7,500

Maximum engine speed

with one-part metal cutting tool

1)

rpm

7,370 I 7,370 I 8,100

7,370 I 8,100 I 7,370

Maximum spindle speed

with one-part metal cutting tool

1)

rpm

10,000

10,000

Idling speed

rpm

3,000 I 3,000 I 2,500 3,000 I 2,500 I 2,500

Carburetor

Type diaphragm

carburetor

diaphragm

carburetor

Ignition system

Type

electronic

electronic

Spark plug

Type

NGK BPMR 8Y

NGK BPMR 8Y

Electrode gap

mm

0.6 - 0.7

0.6 - 0.7

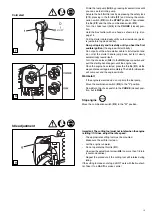

Sound power level L

WA, eq

per ISO 10884

2) 4)

dB(A)

106.8 | 107.8 | 109

99.5 | 100.5 | 102

Sound pressure level L

pA, eq

at the workplace per ISO 7917

2) 5)

dB(A)

94.9 | 95.1 | 97.1

89.9 | 92 | 91.4

Vibration acceleration a

hv, eq

per ISO 7916

2) 6)

- Right handle (idling speed/maximum speed)

m/s

2

5.1 / 5.7 | 2.1 / 6.2 | 4.8 / 5.5

- Left handle (idling speed/maximum speed)

m/s

2

4.0 / 6.2 | 5.0 / 5.3 | 5.3 / 6.5

- Round handle (idling speed/maximum speed)

m/s

2

7.5 / 6.1 | 4.6 / 9.5 | 4.7 / 6.5

- Handle on shaft (idling speed/maximum speed)

m/s

2

4.8 / 8.1 | 4.4 / 6.0 | 6.3 / 7.8

Fuel consumption per ISO 8893

3)

kg/h

0.35 | 0.36 | 0.44

0.36 | 0.44 | 0.49

Speci

fi

c consumption per ISO 8893

3)

g/kWh

500 | 450 | 454

450 | 454 | 386

Fuel tank capacity

l

0.6 | 0.6 | 0.8

0.6 | 0.8 | 0.9

Mixture ratio (fuel / MAKITA two-stroke oil)

- when using MAKITA oil

50:1

50:1

- when using Aspen Alkylat (two-stroke fuel)

50:1 (2%)

50:1 (2%)

- when using other oils (quality grade: JASO FC or ISO EGD)

50:1

50:1

Gear ratio

14:19 | 14:19 | 17:21

14:19 | 14:19 | 14:19

Weight (not including guard, cutting tool and fuel)

kg

5.1 | 5.1 | 5.9

5.9 | 6.7 | 7.9

1)

The maximum rated speed of the trimmer head is not exceeded when using a MAKITA trimmer head.

2)

Figures derived in equal part from idle and top-speed operation (per EN-ISO 11806).

3)

At max. power.

4)

Uncertainty K

WA

= 2,5 dB(A).

5)

Uncertainty K

pA

= 2,5 dB(A).

6)

Uncertainty K = 2

m/s

2

.