Troubleshooting

Model TE100

Electronic Small Bagging Scale

6-2 Revision

001

6.3.2 Scale Does Not Return to Zero

If the scale reading does not return to zero after package has been removed from the spout, check the

following items:

1. Check the calibration of the TE100. Refer to Chapter 3.6 Calibration.

2. Check for anything that might interfere with the natural motion of the spout. Any items, such as

cords, hoses, etc., that would impede or change the movement of the spout must be removed.

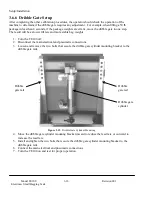

3. Check spout to make sure it is not rubbing on the scale cabinet. If the spout touches the scale

cabinet, it will cause the inconsistent weighments.

4. Check to see if product is building up and sticking inside the spout.

6.3.3 The Machine Is Unable To Auto Correct To The Target Weight

If the auto-correct feature is unable to adjust the fill cycle so that the package weight matches the desired

target weight, follow the steps below:

1. Adjust the offset for the automatic weight correction feature. Refer to 3.6.4 Adjusting Density

Correction Setting.

2. Adjust the actuation speed of the shut off gate. Adjust as necessary. Refer to 7.2.4 MAC Valve

Flow Control Adjustment.

6.3.4 The Weighments Fluctuate Between Too Light and Too Heavy

If the TE100 is inconsistent in delivering package weights, and the weights are always either too heavy,

or too light, follow the steps below:

1. Verify that the product flow is consistent and stable.

2. Check for consistent head pressure of product above the machine. Head pressure is the amount

of product that is always in the hopper immediately above the TE100. It is very important to

keep the TE100 from running out of material. As the TE100 runs out of product the weighment

accuracy will vary widely. A good rule of thumb is to have enough product in the hopper to fill

approximately 20 packages at all times. This amount may vary slightly depending upon product

characteristics.

3. Check the calibration of the TE100. Refer to Chapter 3.6 Calibration.

Содержание TE100

Страница 1: ...Taylor Products Model TE100 Electronic Small Bagging Scale Operation and Maintenance Manual ...

Страница 6: ...Model TE100 Electronic Small Bagging Scale iv Revision 001 This Page Intentionally Left Blank ...

Страница 14: ...Model TE100 Electronic Small Bagging Scale xii Revision 001 This Page Intentionally Left Blank ...

Страница 58: ...Troubleshooting Model TE100 Electronic Small Bagging Scale 6 4 Revision 001 This Page Intentionally Left Blank ...

Страница 76: ...Glossary Model TE100 Electronic Small Bagging Scale Glossary 2 Revision 001 This Page Intentionally Left Blank ...

Страница 78: ...Index Model TE100 Electronic Small Bagging Scale Index 2 Revision 001 This Page Intentionally Left Blank ...

Страница 80: ...Appendix A Model TE100 Electronic Small Bagging Scale A 2 Revision 001 This Page Intentionally Left Blank ...

Страница 82: ...Appendix B Model TE100 Electronic Small Bagging Scale B 2 Revision 001 This Page Intentionally Left Blank ...

Страница 84: ...Appendix C Model TE100 Electronic Small Bagging Scale C 2 Revision 001 This Page Intentionally Left Blank ...

Страница 86: ......

Страница 88: ......

Страница 90: ......

Страница 91: ...Machine Type TE100 Dwg Name ISO 4 dwg Dwg View Scale Cabinet Exploded View ...

Страница 92: ......

Страница 94: ...Appendix D Model TE100 Electronic Small Bagging Scale D 2 Revision 001 This Page Intentionally Left Blank ...

Страница 95: ...Machine Type TE100 Dwg Name ECT146ASY dwg Dwg View Controller Circuit Board ...

Страница 98: ...This Page Intentionally Left Blank ...