IO-390-D Series Engine Maintenance Manual

72-20

© 2020 Avco Corporation. All Rights Reserved

Page 162

March 2020

IO-390-D Series Engine Maintenance Manual

NOTICE:

There are two types of springs used for the seal spring. One type has a hook on

each end; the hooks are joined together. The other type has threaded ends; one

end will be screwed into the other end.

(d)

Remove the spring from the groove (open portion) of a new solid-ring oil seal (Figure

48).

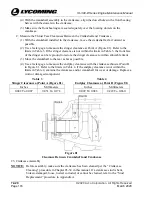

(e)

Put a brass pin approximately 9/32 in. diameter by 3 in. long through the crankshaft

propeller flange bushing to hold both sides of the seal in place as shown in Figure 49.

(f)

Apply a thin film of Lubriko

®

M-6 grease or equivalent on the sealing surface of the seal,

around the crankshaft at the sealing surface, and on the outer edge of the crankshaft

flange.

(g)

Install the oil seal over the edge of the crankshaft propeller flange with the groove (open

portion) of the seal towards the crankshaft propeller flange. Refer to Figure 49.

(h)

Install the Crankshaft Oil Seal Installation Tool ST-383 under the seal and over the edge

of the crankshaft propeller flange as shown in Figure 49. Use even pressure with your

hand, carefully turn the tool to force the oil seal over the crankshaft propeller flange and

use care not to damage the seal.

Figure 49

Crankshaft Propeller Flange Showing the Installation of the Solid-Ring Oil Seal

NOTICE:

There are two types of springs used for the seal spring. One type has a hook on

each end; the hooks are joined together. The other type has threaded ends; one

end will be screwed into the other end.

(i)

Put the seal spring around the crankshaft, join the two ends together. The spring must be a

continuous circle around the crankshaft with no kinks or twists.

(j)

Work the spring into position in the groove (open portion) in the rear side of the oil seal.

(k)

Use ethyl alcohol and disposable wipes to clean the outer surface of the seal and the

crankcase seal bore recess.

This oil seal installation procedure is completed after the crankcase halves are joined together.

Refer to the latest revision of Service Instruction No. 1324 for any new details.