IO-390-D Series Engine Maintenance Manual

72-20

© 2020 Avco Corporation. All Rights Reserved

Page 160

March 2020

IO-390-D Series Engine Maintenance Manual

(h)

If there was no gap, the crankshaft gear is seated correctly.

(i)

Complete the final torque of the crankshaft gear bolt to 204 in.-lb (23.05 Nm).

CAUTION

IN THE NEXT STEP, DO NOT BEND TABS OF THE

LOCKPLATE OVER THE CORNERS OF THE CRANKSHAFT

GEAR BOLT HEAD UNTIL AFTER THE BOLT IS FINAL

TORQUED. DO NOT DECREASE THE TORQUE ON THE

CRANKSHAFT GEAR BOLT TO ALIGN THE LOCKPLATE

TABS.

(12)

If necessary, turn the crankshaft gear bolt up to one additional hex to align the flats of

the bolt head with the tabs on the lockplate. Bend the tabs on the lockplate onto the flats

of the crankshaft gear bolt to hold the bolt securely in place.

C.

Expansion Plug Installation

NOTICE:

If a constant speed propeller is used, there is no expansion plug. Otherwise, a new

expansion plug is necessary for this procedure. Refer to the applicable Illustrated

Parts Catalog for the part number.

(1)

Remove gasket maker from the crankshaft with acetone-soaked wipe.

NOTICE:

Make sure the surface is clean and that there is no debris or gasket material to

ensure a good seal when the new bead of gasket maker is applied in the next

step.

(2)

Apply a bead of Loctite

®

#2 Non-Hardening Gasket Maker or equivalent to the perimeter

of a new expansion plug.

NOTICE:

A driver and a press table can be used to press the expansion plug in the

crankshaft bore.

(3)

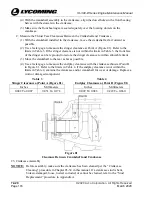

Install the new expansion plug with the convex side out (Figure 46).

(4)

Install the plug where it is seated firmly in the bottom of the crankshaft bore.

(5)

Remove excess gasket material with a clean cloth soaked with acetone.

Initial Plug Installation Correct Plug Seating

(Convex Side Out)

Figure 46

Installed Expansion Plug