8. Maintenance and Inspection

8-2

(2)

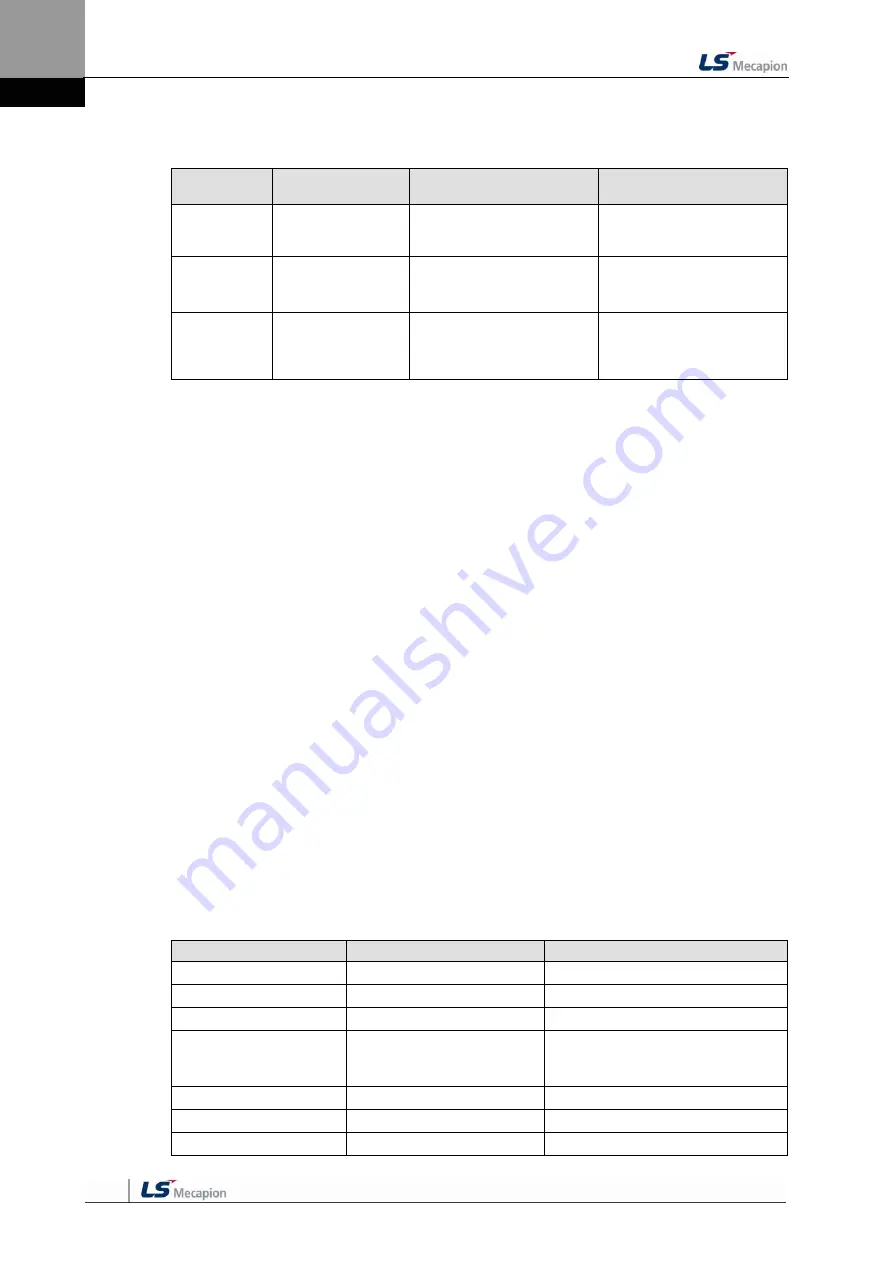

Servo Drive Inspection

Inspection

Item

Inspection Period

How to inspect

What to do if abnormality is

found

Cleaning of the

main body and

the board

At least once a year

Check if there is any dust or

oil on it.

Clean with air pressure or

cloth.

Loose screws

At least once a year

Check whether screws on

terminals and connectors are

loose.

Fasten the screws.

Defective parts

on the main

body or the

board

At least once a year

Check whether there is any

discoloration, damage, or

disconnection caused by heat.

Contact our company.

8.1.3

Parts Replacement Cycle

The following parts may experience low performance or malfunction because of mechanical

friction and aging. It is therefore important to conduct regular maintenance checks and

replace parts.

1.

Smoothing condenser: This part ages because of the impact of ripple current and other factors. Its

lifespan greatly depends on the surrounding temperature and environment. When continuously

used in a air-conditioned ordinary environment, it lasts 10 years on average. Inspect it at least

once a year because it ages rapidly over a short period of time once it starts to do so. (Inspect more

frequently when it gets closer to its obsolescence.)

※

Criteria for visual inspection:

a.

Case's condition: Expanded sides and bottom of the case

b.

Lid's condition: Notable expansion, severe cracks, or broken parts

c.

Explosion valve's condition: Notable valve expansion and operation

d.

Besides, check regularly if there is any crack, broken part, discoloration, or leak on the exterior.

A condenser shall be deemed obsolete when its capacity becomes 85[%] or lower of the rated

capacity.

2.

Relays: Bad connection occurs because of wear and tear at the contact caused by switching

current. A relay is deemed obsolete when its accumulated switching reaches 100,000 times as it

depends greatly on power capacity.

3.

Motor bearing: Replace when it reaches 20,000 to 30,000 hours of operation at the rated speed

under the rated load. Replace if abnormal sound or vibration is detected during inspection, which

are dependent on operating conditions.

[Standard Part Replacement Cycle]

Part Name

Standard Replacement Cycle

Method

Smoothing condenser

7-8 years

Replace (decide after inspection).

Relays

-

Decide after inspection.

Fuses

10 years

Replace.

Aluminum electrolytic

condensers

on printed boards

5 years

Replace with new boards (decide after

inspection).

Cooling fans

4-5 years

Replace.

Motor bearings

-

Decide after inspection.

Motor oil seals

5,000 hours

Replace.

Содержание L7 A001

Страница 1: ...VER 1 5...

Страница 2: ......

Страница 32: ...1 Product Components and Signals 1 20...

Страница 38: ...2 Installation 2 6...

Страница 54: ......

Страница 188: ...7 Product Specifications 7 26 L7 A020 L7 A035 Weight 2 5 kg cooling fan included...

Страница 210: ...8 Maintenance and Inspection 8 14...

Страница 211: ...9 Appendix 9 1 9 Appendix...

Страница 218: ...9 Appendix 9 8...

Страница 221: ......

Страница 222: ......