Electrode angle

The angle which the electrode makes with the work is important to

ensure a smooth, even transfer of metal. The recommended angles

for use in the various welding positions are covered later.

Correct travel speed

The electrode should be moved along in the direction of the joint being

welded at a speed that will give the size of run required. At the same

time the electrode is fed downwards to keep the correct arc length

at all times. As a guide for general applications the table below gives

recommended run lengths for the downhand position.

Correct travel speed for normal welding applications varies between

approximately 125–375 mm per minute, depending on electrode size,

size of run required and the amperage used.

Excessive travel speeds lead to poor fusion, lack of penetration, etc.

Whilst too slow a rate of travel will frequently lead to arc instability, slag

inclusions and poor mechanical properties.

Run length per electrode – BOC Smootharc 13

Electrode

Size (mm)

Electrode

Length (mm)

Run Length (mm)

Minimum

Maximum

4.0

350

175

300

3.2

350

125

225

2.5

350

100

225

Correct work preparation

The method of preparation of components to be welded will depend on

equipment available and relative costs. Methods may include sawing,

punching, shearing, lathe cut-offs, flame cutting and others. In all

cases edges should be prepared for the joints that suit the application.

The following section describes the various joint types and areas

of application.

3.5 Types of joints

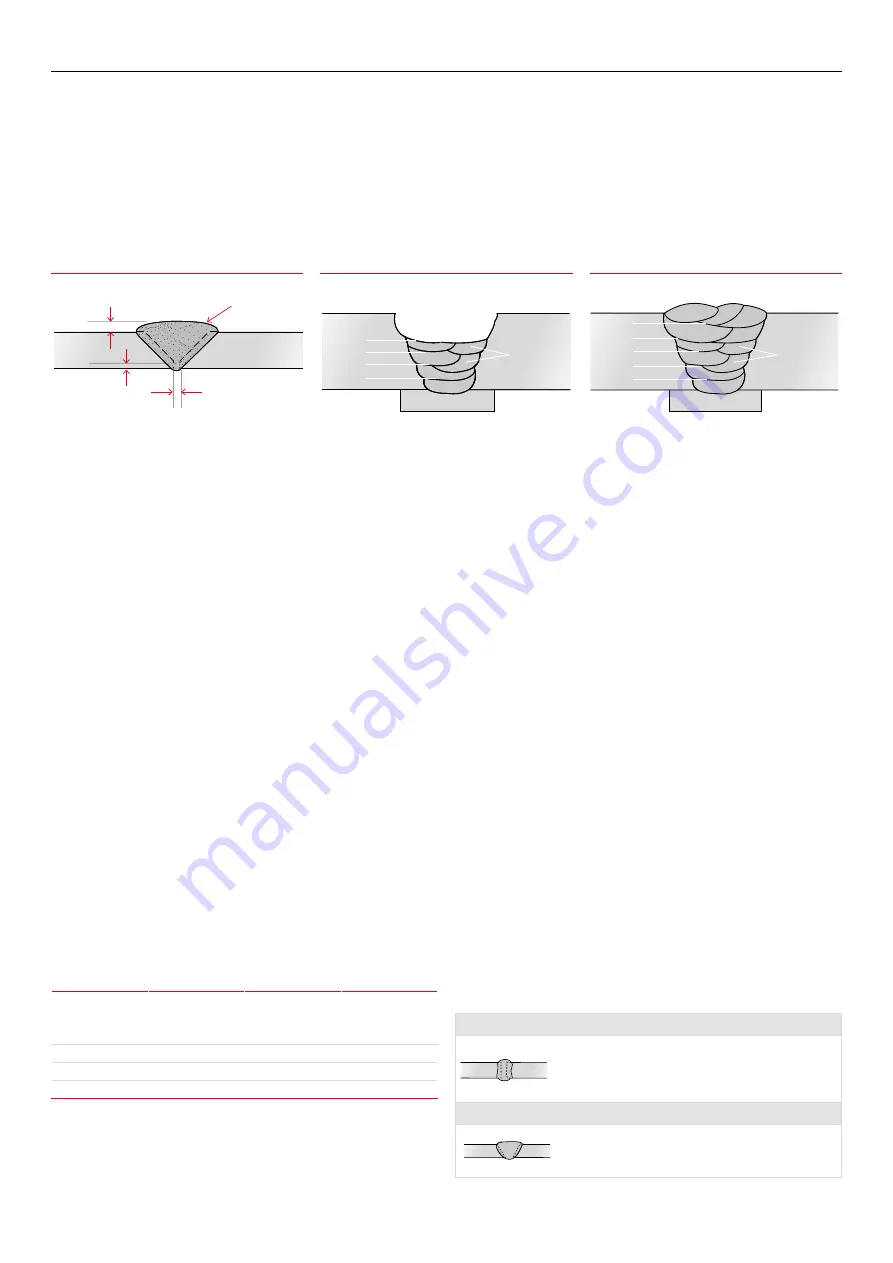

Butt welds

A butt weld is a weld made between two plates so as to give continuity

of section. Close attention must be paid to detail in a butt weld to ensure

that the maximum strength of the weld is developed. Failure to properly

prepare the edges may lead to the production of faulty welds, as correct

manipulation of the electrode is impeded.

Two terms relating to the preparation of butt welds require explanation

at this stage. They are:

→

Root Face: the proportion of the prepared edge

that has not been bevelled.

→

Root Gap: the separation between root

faces of the parts to be joined.

Various types of butt welds are in common use and their suitability for

different thickness of steel are described as follows:

Square Butt Weld

Weld Beads

Weld Beads

Layers

Layers

70˚ - 85˚

Electrode

Slag

Weld Pool

Weld Metal

Arc

Direction Of Welding

The edges are not prepared but

are separated slightly to allow fusion through the full thickness

of the steel. Suitable for plate up

to 6 mm in thickness.

Single ‘V’ Butt Weld

Weld Beads

Weld Beads

Layers

Layers

70˚ - 85˚

Electrode

Slag

Weld Pool

Weld Metal

Arc

Direction Of Welding

This is commonly used for plate up to 16 mm in thickness and on

metal of greater thickness where access

is available from only one side.

Electrode Angle for 1st and 2nd Layers

Electrode Angle for Subsequent Layers

Butt Welding

Weld Face

Face Reinforcement

Root Face

Root Gap

Weld Beads

Weld Beads

Layers

Layers

70˚ - 85˚

Electrode

Slag

Weld Pool

Weld Metal

Arc

Direction Of Welding

Weld Beads

Weld Beads

Layers

Layers

70˚ - 85˚

Electrode

Slag

Weld Pool

Weld Metal

Arc

Direction Of Welding

17

BOC Smootharc Advance II MIG 400R Operating manual