STEP 9

STEP 9

A

B

STEP 9

STEP 9

STEP 9

A

B

C

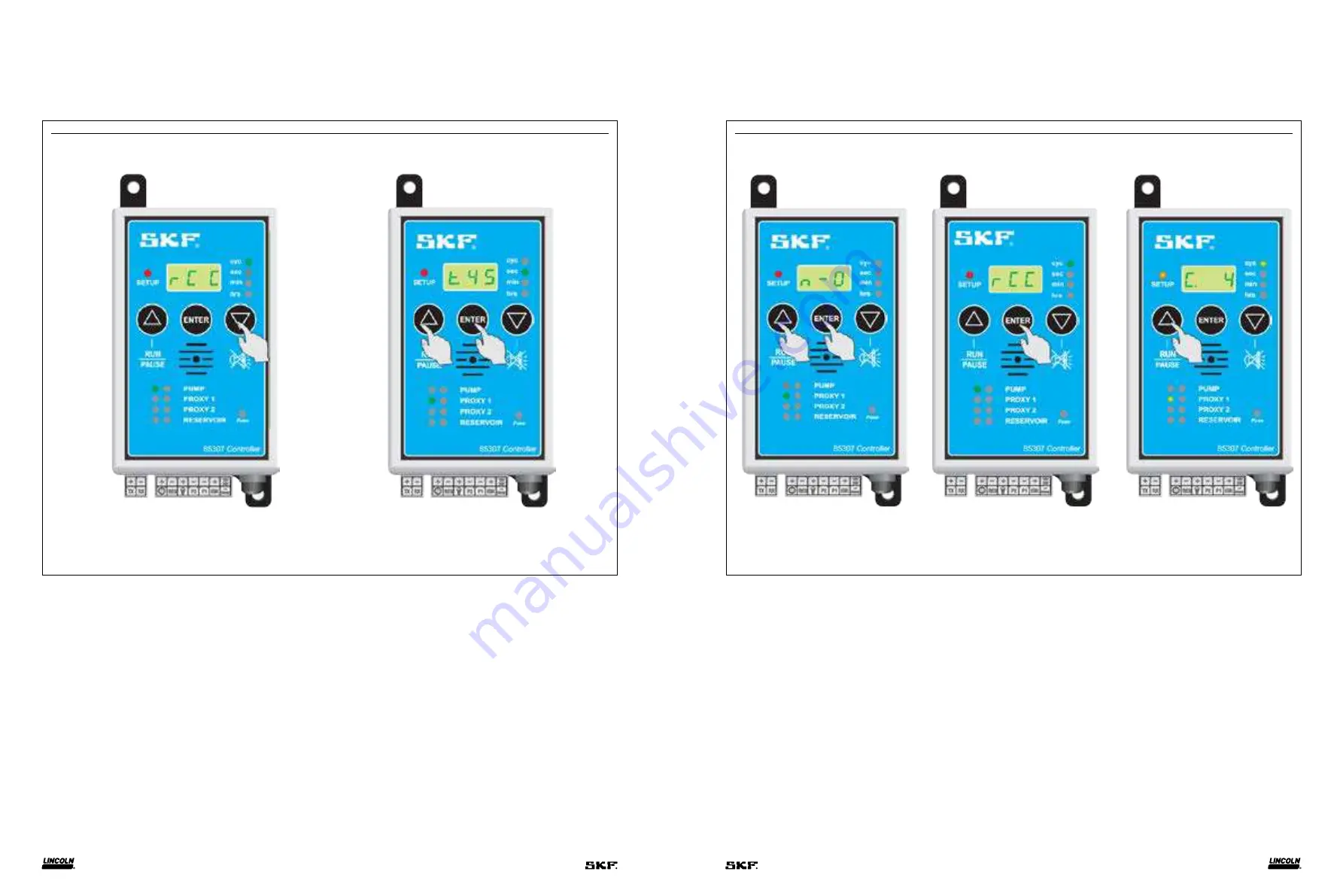

Fig. 36

Setup mode

Progressive-line system with reservoir monitoring using run cycle counter

1

Refer to

steps 1–5

on

.

2

To use

rCC

(run cycle counter), select

∇

(

Fig. 36 A

).

If

Δ

is pressed by accident, continue to press

Δ

until

rCC

displays.

During run cycle, controller looks for signal from proximity

sensor normally fitted to feeder system ensuring complete

machine is lubricated adequately.

Some calculation is necessary to calculate cycles required

through specific feeder system used.

3 t

(time out ) appears in display indicating alarm will activate if

sensor does not send signal to controller within set time. This

function is used when flow proximity sensor is installed on feeder.

Piston activates sensor within feeder and sends signal to

controller. Controller resets time out and starts counting down to

start monitoring process. This function continues to work while in

run cycle mode. It is important to set time out greater than cycle

time of specific feeder. This also depends on pump being used.

Press

Δ

to increase time out to desired setting.

4

Press

ENTE

R to confirm (

Fig. 36 B

).

In example, time out of 45 seconds is confirmed.

5 n-O

(normally open) appears in display. This indicates if sensor is

normally open or normally closed. Press

Δ

to choose between

n-O

or

n-C

.

6

Press

ENTER

to confirm choice (

Fig. 37 A

).

7

Press

ENTER

again to confirm use of run cycle counter

(

Fig. 37 B

).

8

Press

Δ

to increase number of cycles required (

Fig. 37 C

).

Remember 1 cycle represents complete cycle of feeder.

For example, should 6 port feeder be used, 1 cycle indicates

feeder has lubricated all 6 points. 1 cycle is not equal to 1 minute

run time. The larger the feeder, the longer it takes to reach 1 cycle

9

After selecting amount of cycles, press

ENTER

to confirm.

Fig. 37

22

23