7

INSTALLATION

E27 Gearless - Installation and maintenance

5323 en - 2018.04 / c

4.2 - Prolonged storage (> 3 months)

- Place the machine in a sealed waterproof enclosure with

a dehydrating bag inside corresponding to the volume to be

protected and the degree of humidity of the location.

- The bearings which can not be regreased must be replaced

after a storage longer than 3 years.

5 - INSTALLATION

5.1 - Before installation

If the equipment has been stored for several months, it is

essential to check the correct insulation between the phases

and the earth terminal on the motor (minimum 100 MΩ at

500 V D.C. for 60 seconds) after having disconnected all the

electronic circuits if necessary.

Do not apply the megohmmeter to the terminals of the

thermal sensors as this may damage them.

If the required value is not reached, dry the motor using

internal or external heating.

Drying using external heating

- Place the motor in an oven at 70°C for at least 24 hours until

the correct insulation is obtained (100 MΩ).

- Take care to increase the temperature gradually to clear the

condensation.

- After drying at ambient temperature during the cooling

phase, check the insulation value regularly, as it will initially

tend to fall, then rise.

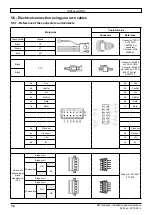

Drying using internal heating (drawing 1)

- Connect motor windings V1 and W1 in parallel in relation

to U1.

- Read off the resistance between U and V//W.

- Apply a low voltage D.C. current to them (to obtain 10% of

the rated current calculated using the winding resistances),

then increase the voltage until 50% of the rated current is

reached

- Maintain the power for 4 hours. The temperature of the

motor should increase slightly.

If the brakes are released, the sheave will move

slightly on power-up (angular setting of the rotor in

relation to the stator).

U1

I

dc

< 50% In

U

dc

V1

W1

Drawing 1

Winding connections

for drying using

internal reheating

5.2 - General recommendation

The installation must comply with the motor characteristics

indicated on the nameplate (see section 1).

It must include electrical safety devices.

Check that the handling equipment (slings, etc.) is suitable

for the weight of the machine.

Use the attachment points provided on the machine.

Check that the cables are correctly positioned so that they

are not damaged.

Provide the necessary mechanical protection devices to

prevent people working on the machine becoming caught or

trapped by the sheave and/or the cables.

During building works, we recommend to protect the brakes

and micro-switches against dust (by wrapping them into a

shrink film for example). If the site is permanently subject to

dust, we recommend to fit the brakes cover available as an

option.

The motors must be installed in such a way that the cooling

air (not too damp, dust-free, and containing no corrosive

gases or vapors) circulates freely.

For the ease of access to the encoder, we recommend to

install the motor with a minimum distance of 200mm between

the cast iron cover protecting the encoder and the wall of the

elevator shaft.

5.3 - Mechanical installation

5.3.1 - Lifting the motor

Pic. 3 : Lifting the motor (for illustration only)

Weight of the motor (kg)

E27S

E27M

E27L

93 kg

106 kg

167 kg

Содержание E27 Series

Страница 4: ...4 E27 Gearless Installation and maintenance 5323 en 2018 04 c...

Страница 15: ......

Страница 46: ...30 31 NOTES...

Страница 109: ......

Страница 110: ......

Страница 111: ......