Mechanical installation

Mounting of g500 short/servo adapters with clamping connection

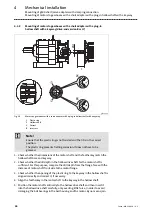

Torque plate assembly

47

Lenze ¯ MA 12.0018 ¯ 4.1

4.3.14

Torque plate assembly

¯

In order to prevent tensioning, the machine shaft should run with good

concentricity.

¯

Use screws and nuts of the 8.8 property class.

¯

Manufacture washers according to the dimensions indicated in the table below if

they are not included in the scope of supply.

¯

Surface roughness of washers and the fixing strap approx. Rz 25.

¯

Mount the rubber buffers with the washers in the fashion shown (Fig. 16 ) on

both sides of the gearbox torque plate and at the fixing strap of your machine.

¯

Tighten the screws until the rubber buffers are pre−stressed by the dimension

D

c7.

¯

Tighten the screwed connection using 2 nuts to secure it.

Screws, nuts, and the fixing strap at the machine are not included in the scope of supply

c

7

c

c

6

c

6

d

5

d

D

g50BS113...g50BS245

D

c

c

6

d

5

d

g50BS280...g50BS319

Fig. 16

Dimensions of washers and rubber buffers

Gearbox

Dimensions

Pretension

Washer

Code

Type

d [mm]

D [mm]

c [mm]

D

c

7

[mm]

d

5

[mm]

c

6 min.

[mm]

G50BS113

g500−S130

11

30

12

1

30

2.5

G50BS122

g500−S220

11

30

12

1

30

2.5

G50BS140

g500−S400

13

40

12

1

37

3

G50BS166

g500−S660

13

40

12

1

37

3

G50BS195

g500−S950

13

40

12

1

37

3

G50BS221

g500−S2100

17

50

2x12

2

50

3

G50BS231

g500−S3100

21

60

2x12

2

60

4

G50BS245

g500−S4500

26

72

2x12

2

72

5

G50BS280

g500−S8000

25

80

40

7

100

10

G50BS314

g500−S14000

31

120

50

5

140

12

G50BS319

g500−S19000

31

120

50

7

140

12

Note!

Solvents, oils, greases, and fuels damage the rubber elements. Be

absolutely sure to prevent contact with these substances!