Mechanical installation

Mounting of g500 short/servo adapters with clamping connection

Mounting of motors to gearboxes with a short adapter with a plug−in hollow shaft with a keyway

36

Lenze ¯ MA 12.0018 ¯ 4.1

4.3.9

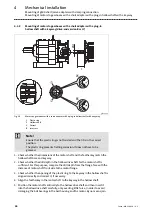

Mounting of motors to gearboxes with a short adapter with a plug−in

hollow shaft with a keyway (drive−end version B or H)

0

1

ü

û

l

Ød

g500−X−010

Fig. 10

Motors on gearboxes with a short adapter with a plug−in hollow shaft with a keyway

1

Plastic ring

2

Hollow shaft

A

Correct

B

Incorrect

Note!

Ensure that the plastic ring is not twisted and that it is in the correct

position.

The plastic ring prevents fretting corrosion. It does not have to be

greased.

1. Check whether the dimensions of the motor shaft and the featherkey match the

hollow shaft bore and keyway.

2. Check whether the drill depth in the hollow drive shaft for the motor shaft is

sufficient. For this purpose, compare the drill depth from the flange face with the

distance of motor shaft front side to the motor flange.

3. Check whether the opening of the plastic ring to the keyway in the hollow shaft is

aligned correctly and correct it, if necessary.

4. Align the featherkey in the motor shaft to the keyway in the hollow shaft.

5. Position the motor shaft centrically to the hollow drive shaft and then insert it

into the hollow drive shaft carefully, only exerting little force, in order to avoid

damaging the ball bearings in the bell housing and the motor. By no means join