6

cold air throughout the cabinet which may result in

warm spots.

Condenser Fan Pressure Switch:

Some freezer units, to maintain proper system

operation, may be equiped with a pressure switch

that operates the condensing unit fan.

Maintenance

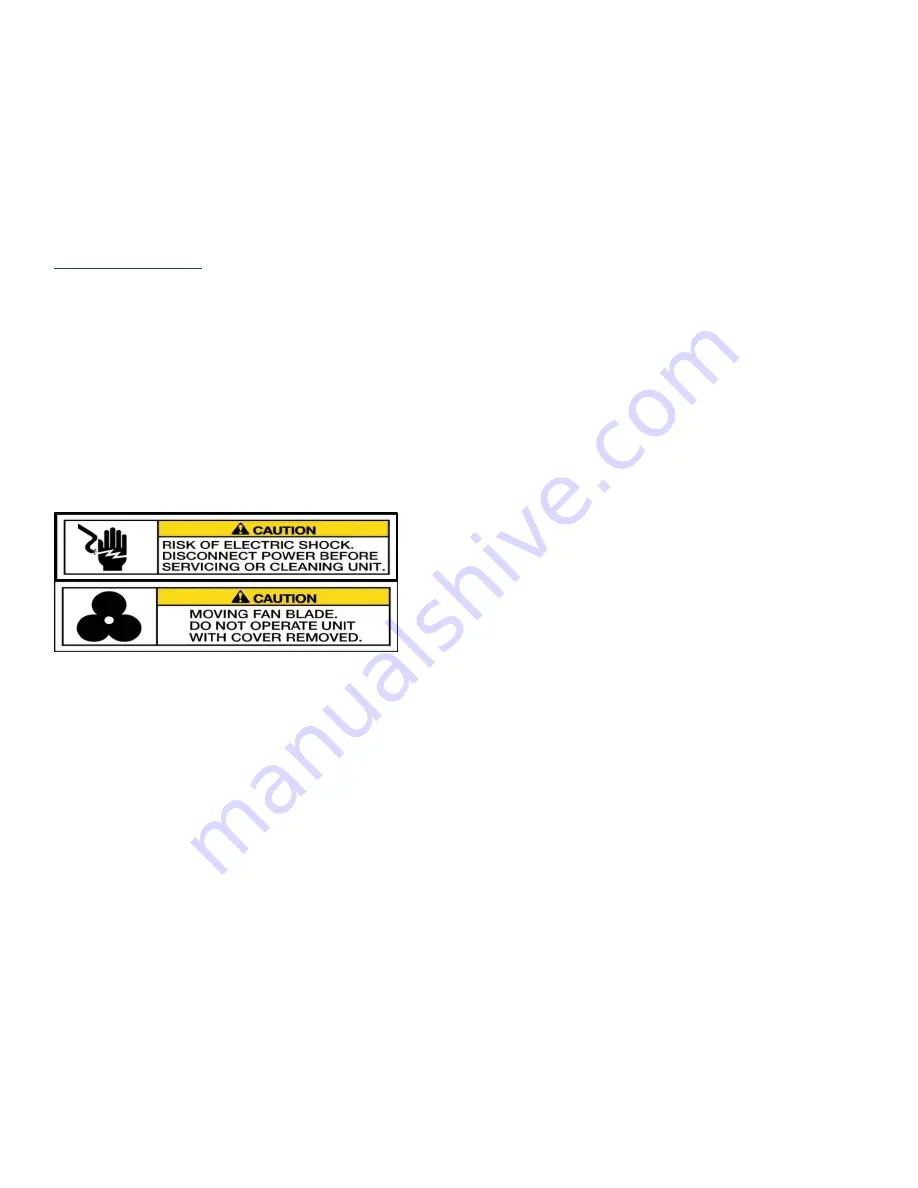

Note: Component parts shall only be replaced with

like components. Maintenance and repair of the

electrical and refrigeration systems should only be

done by trained and qualified personnel.

Disconnect power before performing service.

Certain models may contain multiple voltages.

Leer does not assume responsibility for any

damage to people or things deriving from violation,

improper use, or in any case not in compliance

with Leer’s instructions.

Cleaning the Freezer:

The freezer should be

cleaned annually. In corrosive environments such

as coastal regions and areas where deicing

chemicals and road salts are used, more frequent

cleaning is recommended.

The exterior of the freezer can typically be cleaned

with the use of detergents dilluted in warm water

followed with a tap water rinse. The exterior paint is

capable of withstanding the use of polishing

compounds and most solvents. If using stronger

cleaning agents, they should be tested on a small,

inconspicuous areas prior to application onto visible

surfaces of the freezer. If cleaning the interior of the

freezer, the use of detergents with strong odors (i.e.

citrus based cleaners), abrasive cleaners containing

chlorine bleach, and any form of solvent based

cleaners are not reccommended. They may leave

objectionable odors inside the cabinet which may be

absorbed by the ice being stored in the freezer.

Cleaning Door Gaskets:

Door gaskets may

mildew and stiffen over time. The gasket is made of

a soft, flexible rubber-like material that can be

cleaned using most kitchen and bath cleaners

designed for mildew removal. Review manufacturer

information and instructions on any cleaning agent

prior to use to determine the cleaner’s compatability

with the surface being cleaned.

Cleaning Condenser Coils:

It is recommended to inspect and clean the

condenser coil and fan blades every 3 months.

There are a variety of methods available for

cleaning the condenser coils. Debris are being

drawn into the coil by the condenser fan and the

debris should be removed in the opposite direction.

•

The simplest and preferred method would

involve the use of a vacuum cleaner to suck the

debris out of the coil from the outside surface.

•

Another method is using compressed air to blow

dust from the coil. The debris should be blown

out from the inside surface of the coil.

WARNING

: When using compressed air, there

may be a cloud of dust released into the air

surrounding the machine.

It is recommended that the service person wear the

proper protective equipment (i.e. safety glasses and

a dust mask) when performing coil cleanings.

Note:

DO NOT use any type of filter media in front

of the condenser coil to trap dust. Filter testing has

proven to create enough restriction of

air flow to reduce the efficiency of the coil’s heat

exchange.

Defrosting the Freezer:

Auto-Defrost cabinet models are equipped to be

self-defrosting and are designed to automatically

enter defrost mode once every four hours. During

the defrost cycle, the power to the refrigeration

system will be automatically re-directed to the

defrost circuit. This will shut down power to the

condensing unit and evaporator fan motors and send

power to a heat element that is attached to the

surface of the evaporator coil. The heat generated

by the element will melt the ice build-up on the

evaporator coil and the resulting melt water will

drain through a tube out of the back wall of the