3-22 COLD WEATHER OPERATION

3-22.1

Cold weather causes lubricants to con-

geal, insulation and rubber parts to become

hard, which may lead to problems found in

bearings, electrical systems, and air systems.

Moisture attracted by warm parts can con-

dense, collect and freeze to immobilize

equipment. The truck/semitrailer operator

must always be alert for indicators of cold

weather malfunctions.

3-22.2

During any extended stop period, nei-

ther the service nor parking brake should be

used as they can freeze up. Use wheel

chocks to secure the vehicle from moving.

3-22.3

Check all structural fasteners, air sys-

tem fittings, gaskets, seals and bearings for

looseness that can develop due to contrac-

tion with cold. Do not over-tighten.

3-22.4

Check tire inflation. Tire inflation de-

creases when the temperature decreases.

3-22.5

Periodically check drain holes in the bot-

tom of the relay valve (for trailers with air

brakes) and storage compartments. They must

be open at all times to avoid moisture en-

trapment.

3-23 HOT WEATHER OPERATION

3-23.1

Hot weather operation can create cer-

tain problems which must be checked. Ex-

pansion of parts result in tightening of bear-

ings, fasteners, and moving parts. Failure of

gaskets or seals can occur.

3-23.2

The semitrailer should be parked in the

shade if possible. Long exposure to the sun

will shorten service life of rubber components

(i.e., tires, light and hose grommets, hoses,

etc.) and paint life.

3-23.3

Check tire pressure early in the day be-

fore beginning operations while the tire is

cool. Replace all valve stem caps after

checking.

3-23.4

If the area is extremely humid, protect

electrical terminals with ignition insulation

spray. Coat paint and bare metal surfaces

with an appropriate protective sealer.

3-23.5

The use of a filter-lubricator in the tow-

ing vehicle’s air delivery system is recom-

mended.

3-21

Содержание 825A

Страница 3: ...MODEL 825A 835 DETACHABLE TRAILER OPERATOR S MANUAL PURCHASED FROM DATE ADDRESS PHONE NO SERIAL NO i...

Страница 8: ......

Страница 12: ......

Страница 14: ...3 2 Figure 3 1 Model 825 Trailer Terminology Figure 3 2 Service Hookups...

Страница 18: ...3 6 Figure 3 3 Hydraulic Controls...

Страница 22: ...3 10 Figure 3 5 Swingout Outrigger Platform Extension...

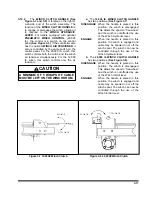

Страница 24: ...3 12 Figure 3 6 Gooseneck Attachment to Frame...

Страница 34: ......

Страница 36: ...4 2 Figure 4 1 Lubrication Points...

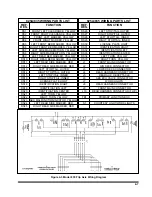

Страница 40: ...4 6 Figure 4 2 Model 825A Wiring Diagram...

Страница 43: ...4 9 Figure 4 4 Tandem Axle Air Ride Suspension System...

Страница 44: ...4 10 Figure 4 5 Tandem Axle W Flip Air Ride Suspension System...

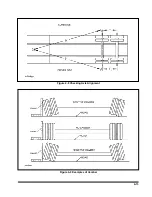

Страница 47: ...4 13 Figure 4 8 Checking Axle Alignment Figure 4 9 Examples of Camber...

Страница 52: ...4 18 Figure 4 12 Axle and Brake Assembly...

Страница 59: ...4 25 Figure 4 18 Mounting Tires and Wheels Figure 4 19 Stud Tightening Sequence...

Страница 69: ...NOTES 5 9...

Страница 70: ......