UH50 Ultrasonic Heat Meter

Subject to change without prior notice

UH 206-101c

Page 1 / 8

Heat Meter Ultrasonic

®

UH50

Installation

UH 206-101c

and Service Instructions

Version: October 2007

Safety information

)

Do not pick up by the electronic unit

)

Be careful of sharp edges (thread, flange,

measuring tube)

)

Installation and removal must be performed

by qualified personnel only

)

Mounting and unmounting are only permitted

when the system is not under pressure

)

After installation, a tightness test must be

conducted with cold pressure

)

Only ever use under service conditions,

otherwise dangers can arise and the warranty

may be voided

)

Breaking the calibration seal voids the

warranty

)

The 110

V

/

230

V versions must only be

connected by an electrician

)

The lithium batteries must be properly

returned

)

Lightning protection cannot be ensured; this

must be provided by the building wiring

)

Only one compartment for the power supply

must be equipped – do not remove the red

locking hatch

General information

The electronic unit is plugged onto an adapter plate

and can be separated by pushing the volume

measuring unit upward.

The packaging should be kept so that the heat

meter can be shipped in its original packing after the

calibation period has elapsed.

If the heat meter was not supplied with a battery

connected, the current date and time must be

entered during start-up (see “Parameter setting”).

The 110 V / 230 V power supply units comply with

safety class II, so the line voltage does not need to

be disconnected when changing the unit.

All cables must be laid at a

minimum distance of

300 mm

from power cables or radio-frequency

cables.

By overpressure, cavitation must be avoided in the

entire measuring range, i.e

. at least 1 bar at q

p

and

approx. 3 bar at q

s

(applies to approx. 80°C).

The heat meter left the factory in perfect safe

condition. Calibration, maintenance, component

replacement, and repairs must only be performed by

trained personnel who are familiar with the hazards

involved. The manufacturer will provide further

technical support on request. Heat meter safety

marks that are relevant for calibration must not be

damaged or removed! Otherwise the warranty and

calibration validity of the device will expire.

Installation

Choose the mounting location (return or flow) in

accordance with the labeling on the heat meter.

Study the table for the dimensions and check that

there is enough clearance.

No inlet or outlet sections are necessary. However,

if the heat meter is installed in the shared return of

two heating systems, e.g. heating and hot water, the

mounting location must be a sufficient distance from

the T element that forms the junction (

min. 10

×

DN

)

to allow the different water temperatures to mix well.

Before the heat meter is installed, the system must

be rinsed thoroughly.

As shown in the examples on Page 2, mount the

volume measuring unit horizontally or vertically

between two shut-off valves in accordance with the

arrow for the direction of flow. The sensors must be

mounted in the same heating circuit as the volume

measuring unit. For installation as a

cold meter,

see

the following notes.

The sensor can be mounted in ball valves, in

pockets or direct immersed. The end of the sensors

must extend in any case as far as the center of the

pipe cross-section. Temperature sensors and screw

joints must be sealed for protection from tampering.

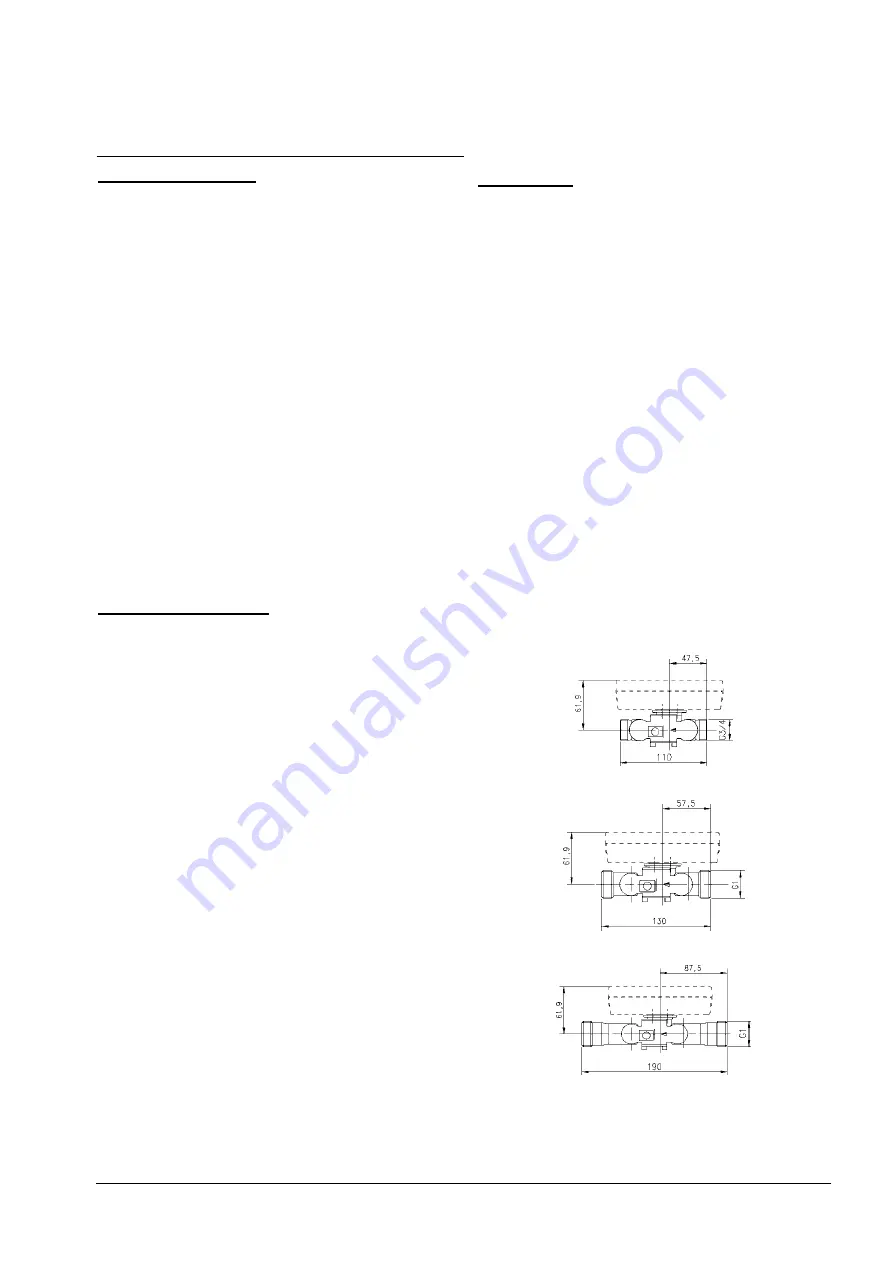

Small heat meters (q

p

0.6 - 2.5 m³/h)

Overall length 110 mm (thread)

Overall length 130 mm (thread)

Overall length 190 mm (thread)

3250 006 101 c