Page 38

Servicing

General comments

• Follow the maintenance guidelines and intervals accurately, so that the equipment stays in sound operating

condition.

• The terms specified for maintenance intervals must be adhered to!

• Maintenance works may only be carried out by skilled personnel!

• Test air storage tank regularly in accordance with the regulation on pressure tanks!

• Allow system testing to be carried out regularly in accordance with DIN/VDE 0701/0702, BGV A2 (this testing

can also be commissioned at LANCIER-Monitoring).

• Only use original LANCIER Monitoring replacement parts!

• After maintenance works tighten all loosened screw joints again!

Maintenance

Cleaning or changing compressor air intake filters

Deadly risk!

Working on open, live equipment!

• Do not operate the equipment with damp hands!

• Caution: live components!

Deadly risk!

Switch off operating voltage!

Risk of injury!

Caution with heated components!

Risk of injury!

Wear protective goggles when blowing out devices.

• Switch off operating voltage!

• Turn and pull filter cap (

83

) to the left (anti-clockwise).

• Pull out filter cartridge (

84

) and then blow with pressurised air.

• Renew filter cartridge (

84

) in the case of heavy contamination or damage.

• Insert filter cartridge (

84

) in the center of the housing.

• Put on filter cap (

83

) and turn right (clockwise) until the marks face each other.

• Carry out maintenance works on the second air intake filter.

• Switch on operating voltage!

83

84

84

83

Содержание RTS 1000

Страница 15: ...Page 15 39 35 37 36 36 23 42 28 27 24 6 33 38 40 41 32 22 29 25 8...

Страница 21: ...Page 21...

Страница 47: ...Page 47 7 16 14 15 15 18 17 13 20 24 8 23 10 6 9 4 22 21 19 8...

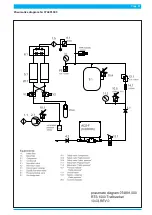

Страница 51: ...Page 51 Pneumatics diagram Nr 074891 000...

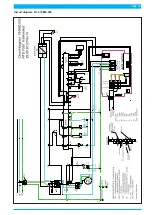

Страница 53: ...Page 53 Circuit diagram Nr 074880 000...

Страница 55: ...Wiring diagram Nr 074881 000 Page 55...