AXE 3 D UNIT 32 R HR

13

EN

cod. 3541B310 - 10/2011 (Rev. 00)

Adjustments from Remote Timer Control

A

If the Remote Timer Control (optional) is connected to the boiler, the above ad-

justments are managed according to that given in table 1. Also, the control pan-

el display (detail 5 - fig. 1) shows the actual room temperature detected by the

Remote Timer Control.

Table. 1

System water pressure adjustment

The filling pressure with system cold, read on the display, must be approx. 1.0 bar. If the

system pressure falls to values below minimum, the boiler card will activate fault F37

(fig. 15).

fig. 15 - Low system pressure fault

A

Once the system pressure is restored, the boiler will activate the 120-second

air venting cycle indicated on the display by FH.

3. INSTALLATION

3.1 General Instructions

BOILER INSTALLATION MUST ONLY BE PERFORMED BY QUALIFIED PERSON-

NEL, IN ACCORDANCE WITH ALL THE INSTRUCTIONS GIVEN IN THIS TECHNICAL

MANUAL, THE PROVISIONS OF CURRENT LAW, THE PRESCRIPTIONS OF NA-

TIONAL AND LOCAL STANDARDS AND THE RULES OF PROPER WORKMANSHIP.

3.2 Place of installation

The boiler unit must be installed in a specific room with ventilation openings to the out-

side as prescribed by current regulations. If there are several burners or suction units

that can work together in the same room, the ventilation openings must be sized for si-

multaneous operation of all the units. The place of installation must be free of flammable

materials or objects, corrosive gases, powders or volatile substances that, conveyed by

the burner fan, can obstruct the internal lines of the burner or the combustion head. The

room must be dry and not exposed to rain, snow or frost.

A

If the unit is enclosed in a cabinet or mounted alongside, a space must be pro-

vided for removing the casing and for normal maintenance operations.

3.3 Plumbing connections

The heating capacity of the unit must be previously established by calculating the build-

ing's heat requirement according to the current regulations. The system must be provid-

ed with all the components for correct and regular operation. It is advisable to install

shutoff valves between the boiler and heating system allowing the boiler to be isolated

from the system if necessary.

B

The safety valve outlet must be connected to a funnel or collection pipe to pre-

vent water spurting onto the floor in case of overpressure in the heating circuit.

Otherwise, if the discharge valve cuts in and floods the room, the boiler manu-

facturer cannot be held liable.

Do not use the water system pipes to earth electrical appliances.

Before installation, clean all the pipes of the system thoroughly to remove any residuals

or impurities that could affect proper operation of the unit.

Carry out the relevant connections according to the diagram in cap. 5 and the symbols

given on the unit.

Water system characteristics

In the presence of water harder than 25° Fr (1°F = 10ppm CaCO3), use suitably treated

water in order to avoid possible scaling in the boiler. Treatment must not reduce the hard-

ness to values below 15°F (Decree 236/88 for uses of water intended for human con-

sumption). Treatment of the water used is indispensable in case of very large systems

or with frequent introduction of replenishing water in the system.

B

If water softeners are installed at the boiler cold water inlet, make sure not to

reduce the water hardness too much, as this could cause early deterioration of

the magnesium anode in the hot water tank.

Antifreeze system, antifreeze fluids, additives and inhibitors

The boiler is equipped with an antifreeze system that turns on the boiler in heating mode

when the system delivery water temperature falls under 6°C. The device will not come

on if the electricity and/or gas supply to the unit are cut off. If it becomes necessary, it is

permissible to use antifreeze fluid, additives and inhibitors only if the manufacturer of

these fluids or additives guarantees they are suitable for this use and cause no damage

to the heat exchanger or other components and/or materials of the boiler unit and sys-

tem. It is prohibited to use generic antifreeze fluid, additives or inhibitors that are not ex-

pressly suited for use in heating systems and compatible with the materials of the boiler

unit and system.

Connection to a storage tank for domestic hot water production

The unit's electronic board is arranged for managing an external storage tank for domes-

tic hot water production. Make the plumbing connections according to the diagram

fig. 16. Carry out: electrical connections as shown in the wiring diagram in cap. 5.4. A

probe

LAMBORGHINI

must be used.

This system requires a different parametrisation. The card Service Menu is accessed by

pressing the Reset button for 10 seconds. Press the Heating buttons to select "tS", "In",

"Hi" or "rE". "tS" means Transparent Parameters Menu, "In" Information Menu, "Hi" His-

tory Menu, and "rE" History Menu Reset. Select "tS" and press the Reset button.

The card is equipped with 20 transparent parameters also modifiable from Remote Con-

trol (Service Menu).Press the Heating buttons to scroll the list of parameters in increas-

ing or decreasing order. Press the DHW buttons to modify the value of a parameter: the

change will be automatically saved.

Change parameter

P02

of the "Transparent Parameters Menu" to

6

.

Press the Reset button to return to the Service Menu. Press the Reset button for 10 sec-

onds to exit to the card Service Menu.

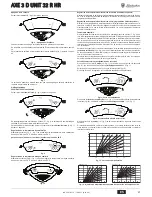

fig. 16 - Diagram of connection to external hot water tank

Key

8

Domestic hot water outlet

9

Domestic cold water inlet

10

System delivery

11

System return

95

3-way valve - 2 wires with spring return (not provided)

3.4 Burner connection

To carry out the burner connection refer to the manual provided by the burner manufac-

turer.

3.5 Electrical connections

Connection to the electrical grid

B

The unit's electrical safety is only guaranteed when correctly connected to an

efficient earthing system executed according to current safety standards. Have

the efficiency and suitability of the earthing system checked by professionally

qualified personnel. The manufacturer is not responsible for any damage

caused by failure to earth the system. Also make sure that the electrical system

is adequate for the maximum power absorbed by the unit, as specified on the

boiler dataplate.

The boiler is prewired and provided with a Y-cable and plug for connection to the elec-

tricity line. The connections to the grid must be made with a permanent connection and

equipped with a bipolar switch whose contacts have a minimum opening of at least 3

mm, interposing fuses of max. 3A between the boiler and the line. It is important to re-

spect the polarities (LINE: brown wire / NEUTRAL: blue wire / EARTH: yellow-green

wire) in making connections to the electrical line. During installation or when changing

the power cable, the earth wire must be left 2 cm longer than the others.

B

The user must never change the unit's power cable. If the cable gets damaged,

switch off the unit and have it changed solely by professionally qualified person-

nel. If changing the electric power cable, use solely

“HAR H05 VV-F”

3x0.75

mm2 cable with a maximum outside diameter of 8 mm.

Heating temperature setting

Adjustment can be made from the Remote Timer Control menu and the boiler

control panel.

DHW temperature adjustment

Adjustment can be made from the Remote Timer Control menu and the boiler

control panel.

Summer/Winter Switchover

Summer mode has priority over a possible Remote Timer Control heating

demand.

Eco/Comfort selection

On disabling DHW from the Remote Timer Control menu, the boiler selects the

Economy mode. In this condition, the

button 7

- fig. 1 on the boiler panel is dis-

abled.

On enabling DHW from the Remote Timer Control menu, the boiler selects the

Comfort mode. In this condition it is possible select one of the two modes with

the

button 7

- fig. 1 on the boiler panel.

Sliding Temperature

Both the Remote Timer Control and the boiler card manage Sliding Tempera-

ture adjustment: of the two, the Sliding Temperature of the boiler card has prior-

ity.

IIIIIII

IIIIII

IIII

I

IIII

IIII

IIII

IIII

IIII

IIII

IIII

IIII

IIII

IIII

III

III

III

IIII

IIIIII

IIIIIIIII

IIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIII

IIIIII

IIII

IIII

IIIIII

IIIII

IIII

IIII

IIII

IIII

IIII

IIII

IIII

I

8

9

95

10

11

Содержание AXE 3 D UNIT 32 R HR

Страница 31: ......