MSD Legend Series Operation & Maintenance Manual | 41

REPLACE WEAR PLATES & BARS

Wear personal protection equipment (PPe) at all

times while welding. Allow only qualified, certified

welders to maintain LaBounty products.

Inspecting Wear Bars & Wear Plates

1.

Measure the thickness of each wear item.

2.

Replace when worn down 1/2 of it’s original

thickness, or as needed.

3. Visually inspect the welds. If the welds show signs

of cracks, the wear item must be replaced.

4.

Replace wear bars and plates if they are missing.

Replace Wear Bars & Wear Plates

1.

Preheat the area within 6 inches of the plates to 400° - 450° F (204° - 233° C). Maintain this temperature throughout

the process.

2.

Using carbon arc gouging, remove the old wear plates or bars from the shear jaw.

3. Grind the surface of the jaw and ensure all weld and carbon residue has been removed and the area is smooth and

clean. Build up the area, if necessary.

4.

Position the new wear plates or bars on the shear and clamp into position.

5.

Weld the wear plates or bars.

6.

Stress relieve each pass by peening and grind the welds smooth.

7.

Wrap the area with a heat blanket and allow to cool slowly.

SLIDE SCREW ADJUSTMENT

The slide screw keeps the upper jaw in line and cutting properly. There is one screw on each side of the shear and they

should be inspected and adjusted every 80 hours.

Do not cycle or move the shear while removing the

slide screw by hand. This will result in severe injury.

Keep clear when the shear is in motion. Avoid pinch

points, such as the upper shear or the shear cylinder.

Severe injury could result.

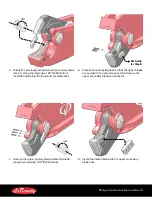

1.

Remove the lock plate bolt and the lock plate.

2.

Using a crescent wrench, unscrew the slide screw from the shear body.

3. Inspect the end of the screw that contacts the upper jaw. If the grease channels are worn away, replace the screw.

4.

Clean the threads and re-lubricate with 2-EP lithium grease.

5.

Apply a layer of grease to where the slide screw comes in contact with the upper shear.

6.

Reinsert the slide screw and tighten until the screw begins to touch the upper shear. Reinstall the lock plate.

7.

Grease the slide screw, as shown in “Shear Lubrication” on page 23.

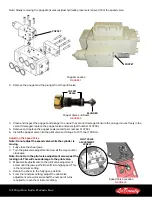

PierCiNg TiP WeAr BArS

uPPer BLADe WeAr BArS

LOWer BLADe WeAr BArS

WeAr PLATeS

Location of Wear Bars & Plates

Figure 34

Содержание MSD Series

Страница 45: ...MSD Legend Series Operation Maintenance Manual 45 SPEED VALVE ASSEMBLY ILLUSTRATIONS Test Port Locations...

Страница 50: ......

Страница 51: ......