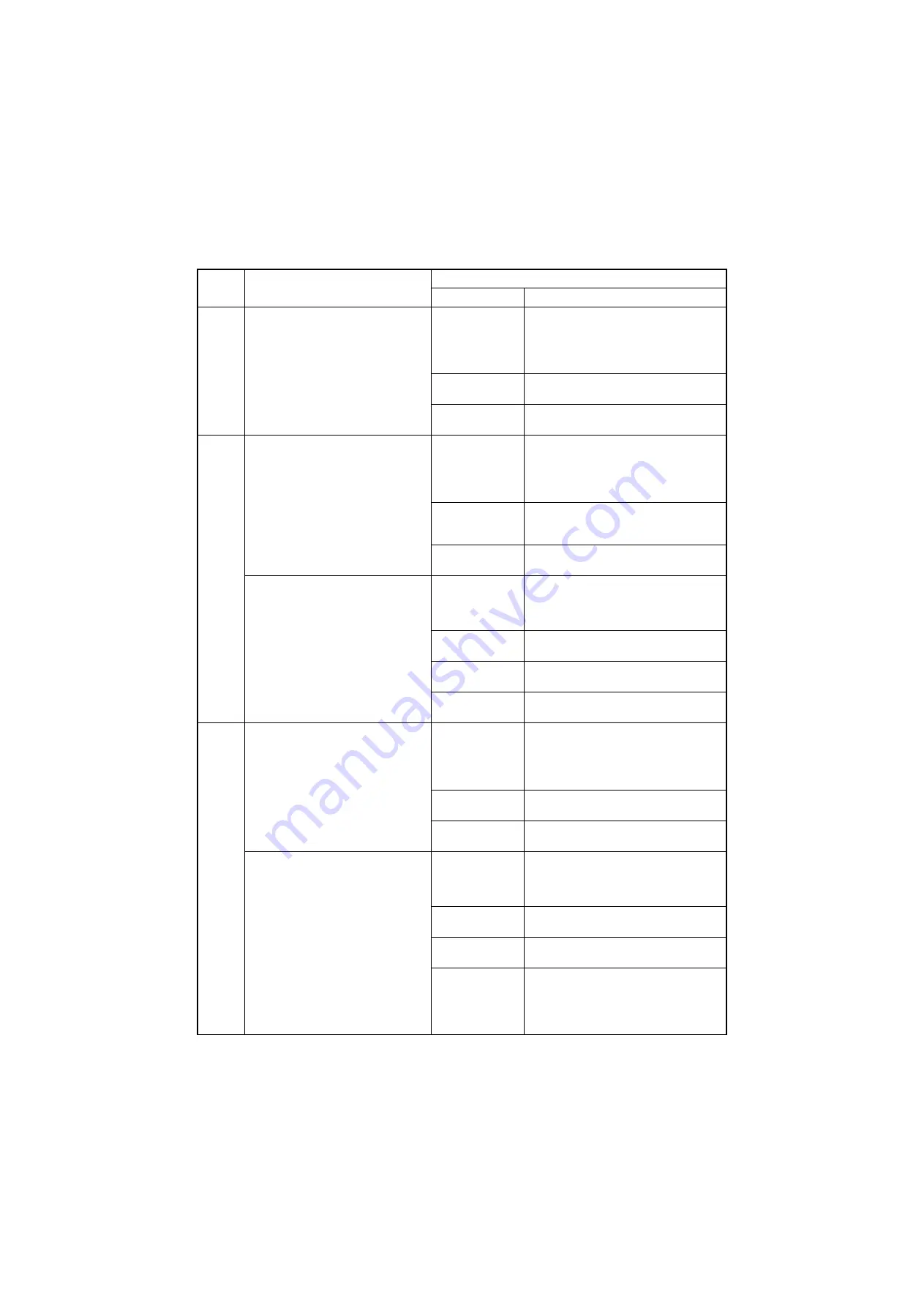

2KR/2KS

1-4-43

C8340

Centerfold staple motor problem

(optional center-folding unit of 3000-

sheet document finisher)

Jam 89 is indicated.

Poor contact in the

connector termi-

nals.

Check the connection of connector YC9 on

the centerfold main PWB and the connector

of the centerfold staple motor, and the conti-

nuity across the connector terminals. Repair

or replace if necessary.

Defective center-

fold staple motor.

Replace the centerfold staple motor.

Defective PWB.

Replace the centerfold main PWB or finisher

main PWB and check for correct operation.

C8350

Centerfold side registration motor 1

problem (optional center-folding unit

of 3000-sheet document finisher)

The home position is not detected when

initial operation even if 1 s passed.

Poor contact in the

connector termi-

nals.

Check the connection of connector YC7 on

the centerfold main PWB and the connector

of centerfold side registration motor 1, and

the continuity across the connector termi-

nals. Repair or replace if necessary.

Defective center-

fold side registra-

tion motor 1.

Replace centerfold side registration motor 1.

Defective PWB.

Replace the centerfold main PWB or finisher

main PWB and check for correct operation.

Roller motor problem (optional docu-

ment finisher)

The roller sensor does not turn on/off

within specified time of the roller motor

turning on.

The roller sensor,

roller motor con-

nector makes poor

contact.

Reinsert the connector. Also check for conti-

nuity within the connector cable. If none,

remedy or replace the cable.

Defective roller

sensor.

Replace the roller sensor.

Defective roller

motor.

Replace the roller motor.

Defective finisher

main PWB.

Replace the finisher main PWB and check

for correct operation.

C8360

Centerfold main motor problem

(optional center-folding unit of 3000-

sheet document finisher)

The motor lock signal is detected above

1 s during driving the centerfold main

motor.

Poor contact in the

connector termi-

nals.

Check the connection of connector YC12 on

the centerfold main PWB and the connector

of the centerfold main motor, and the conti-

nuity across the connector terminals. Repair

or replace if necessary.

Defective center-

fold main motor.

Replace the centerfold main motor.

Defective PWB.

Replace the centerfold main PWB or finisher

main PWB and check for correct operation.

Slide motor problem (optional docu-

ment finisher)

The slide sensor does not turn on/off

within specified time of the slide motor

turning on.

The slide sensor,

slide motor con-

nector makes poor

contact.

Reinsert the connector. Also check for conti-

nuity within the connector cable. If none,

remedy or replace the cable.

Defective slide

sensor.

Replace the slide sensor.

Defective slide

motor.

Replace the slide motor.

Defective finisher

main PWB.

Replace the finisher main PWB and check

for correct operation.

Code

Contents

Remarks

Causes

Check procedures/corrective measures

Содержание TASKalfa 420i

Страница 1: ...SERVICE MANUAL Published in May 2010 842KS113 2KSSM063 Rev 3 TASKalfa 420i TASKalfa 520i ...

Страница 4: ...This page is intentionally left blank ...

Страница 10: ...This page is intentionally left blank ...

Страница 14: ...2KR 2KS This page is intentionally left blank ...

Страница 224: ...2KR 2KS 1 4 66 This page is intentionally left blank ...

Страница 328: ...2KR 2KS 2 3 30 This page is intentionally left blank ...

Страница 371: ...INSTALLATION GUIDE FOR PAPER FEEDER ...

Страница 381: ...INSTALLATION GUIDE FOR 3000 SHEETS PAPER FEEDER ...

Страница 436: ...INSTALLATION GUIDE FOR CENTER FOLDING UNIT ...

Страница 450: ...INSTALLATION GUIDE FOR MAILBOX ...

Страница 458: ...INSTALLATION GUIDE FOR HOLE PUNCH UNIT ...

Страница 470: ...INSTALLATION GUIDE FOR BUILT IN FINISHER ...

Страница 483: ...INSTALLATION GUIDE FOR JOB SEPARATOR ...

Страница 491: ...INSTALLATION GUIDE FOR FAX System ...

Страница 507: ......

Страница 508: ......