6 | Function description

The [Management] tabulator with three dialog windows

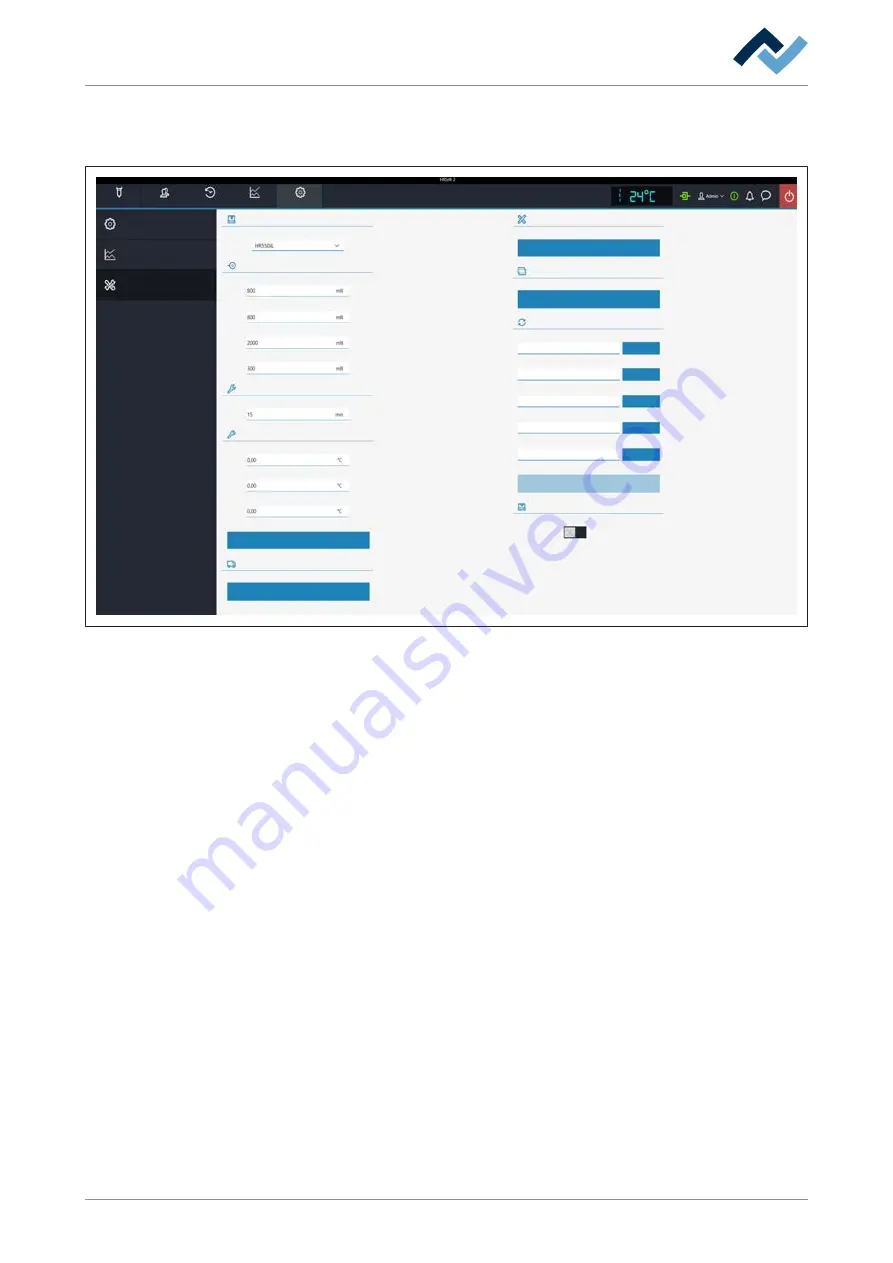

6.12.3 The [device settings] dialog

Use dialog [Device options] to access various pre-settings for the Rework system.

Style

Device selection

Selected device

Rework

Archive

User administration

Profile management

Administration

HRSoft 2 options

Graph options

Device options

Force sensor parameters

Firmware update

System board update file

Power board update file

Satellites update file

Device setup

Optional tools

Pixel shift

Move to transport position

Adjust pixel shift

Firmware update

Start device setup

Select file

Select file

Select file

Temp. offset (120° C)

Channel TC 1

Reduce Z-axis velocity

Distance to reduce z-axis velocity

Force sensor tolerance

Force sensor safety

Force sensor contact level

Force sensor contact level pcb

Send

Channel TC 2

Channel TC 3

Device transport position

Select file

Select file

Xmos update file:

Amtel update file:

Scavenger active

[Device selection]

[Selected device]: to select your Rework system.

[Force sensor parameters]

Set the contact sensors of the placing head pipette. Only change values if the res-

ulting effects are known. Changing these values may cause the pipette to exert too

much or too little force.

Info: The contact force of the soldering nozzle is controlled automatically and can-

not be changed.

– [Force sensor contact level pcb]: contact force on PCB, component and glass

plate where the pipette movement stops.

– [Force sensor contact level]: contact force during dipping at which the dipping

movement stops.

– [Force sensor safety]: contact force stopping the movement during the pipette

fast drive. Do not change these values!

– [Force sensor tolerance ]: Force specification of the hysteresis for pipette drive.

Do not change these values!

Reduce Z-axis velocity]

– [Distance to reduce z-axis velocity]: For the last few millimetres before the con-

tact point, the pipette must switch to slowed contact movement. The 0 value

corresponds to the PCB surface.

a) Enter the distance in millimetres at which to switch to slowed contact move-

ment. For tall components, the distance must be higher.

Ersa GmbH

Operating instructions HR 550 XL EN 3BA00247-01 | Rev. 1

98 / 157

Содержание HR 550 XL

Страница 2: ......

Страница 6: ......

Страница 22: ...2 Technical data PC system requirements Ersa GmbH Operating instructions HR 550 XL EN 3BA00247 01 Rev 1 22 157...

Страница 153: ...9 Spare and wear parts Spare parts Ersa GmbH Operating instructions HR 550 XL EN 3BA00247 01 Rev 1 153 157...

Страница 156: ...10 Annex EC Declaration of Conformity Ersa GmbH Operating instructions HR 550 XL EN 3BA00247 01 Rev 1 156 157...

Страница 157: ......