16

ENGINE

128

Info

The membrane support plate is curved and must point away from the mem-

brane.

An incorrectly installed membrane support plate results in loss of perfor-

mance and increased oil consumption or leaks.

Do not apply thread locker between the membrane and the membrane sup-

port plate since this would impair their function.

16.4.3

Work on the clutch cover

305662-10

–

Remove the shaft seal ring

of the crankshaft.

–

Press in a new shaft seal ring with the open side facing inward until it stops.

Info

Support the clutch cover sufficiently when pressing in.

–

Blow compressed air through the oil channel and check that it is clear.

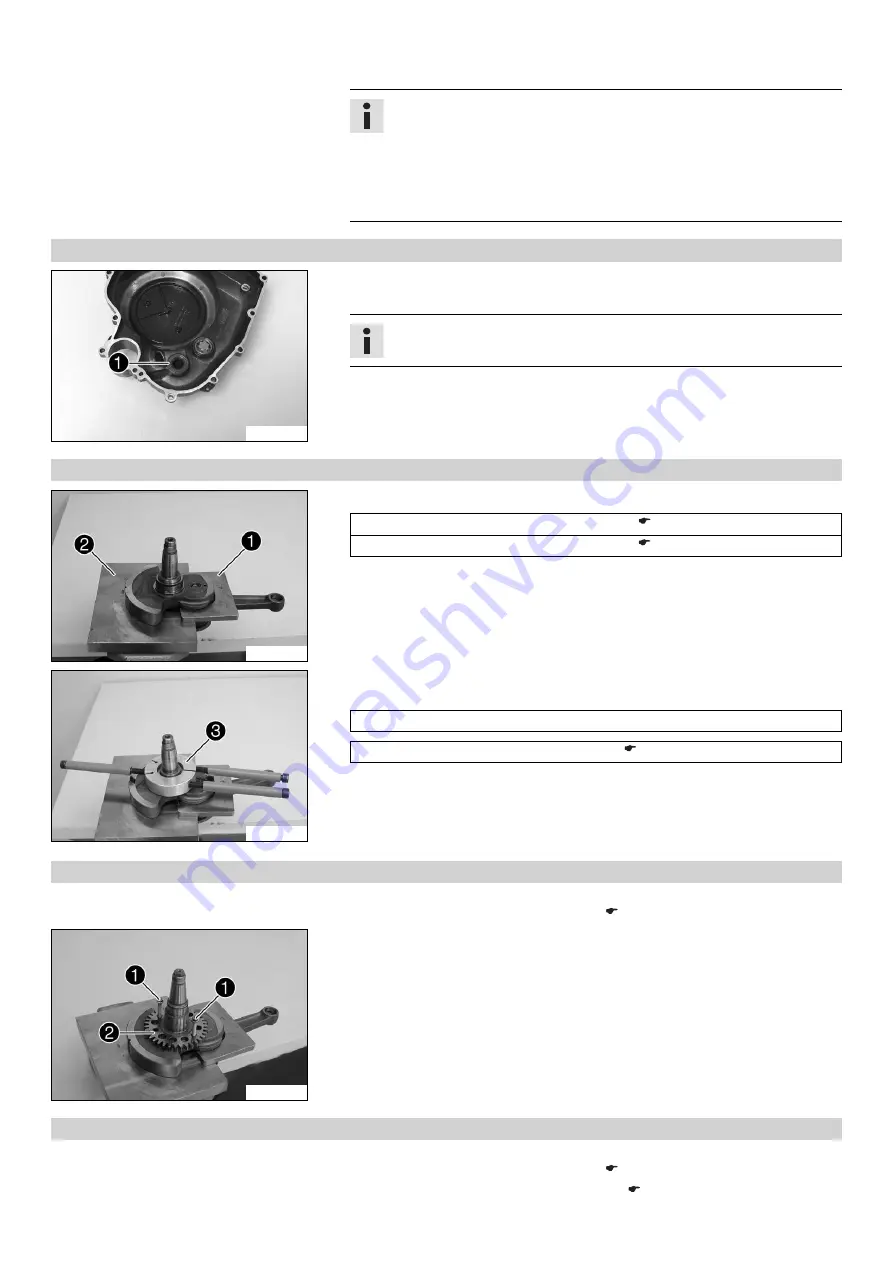

16.4.4

Removing crankshaft bearing inner ring

302145-10

–

Fix the crankshaft with special tools

and

in the vise.

Upper part, pressing-out tool (75029047050) (

Under part, pressing-out tool (75029047051) (

302146-10

–

Heat the special tool

.

Guideline

150 °C (302 °F)

Tool for inner bearing race (58429037043) (

–

Push the heated special tool

on to the inner bearing race, press them hard

together, and pull them together off the crankshaft.

–

Take off the compensation shim.

–

Repeat the operation on the opposite side.

16.4.5

Removing balancer shaft drive wheel

Preparatory work

–

Remove the crankshaft bearing inner ring. (

302147-10

Main work

–

Screw in 2 M6 screws

in the threads. Tighten the two screws evenly to pull the

drive wheel

off the crankshaft.

16.4.6

Changing the connecting rod, conrod bearing, and crank pin

Preparatory work

–

Remove the crankshaft bearing inner ring. (

–

Remove the drive wheel of the balancer shaft. (