4.6

Configuration and function

1

3

4

6

7

8

9

10

5

2

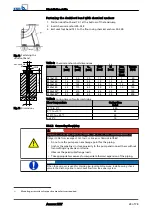

Fig. 3: Sectional drawing

1

Casing wear ring

2

Discharge nozzle

3

Discharge cover

4

Shaft

5

Bearing bracket

6

Suction nozzle

7

Impeller

8

Shaft seal

9

Bearing, pump end

10

Bearing, motor end

The pump is designed with an axial fluid inlet and a radial outlet. The hydraulic

system sits on the extended motor shaft. The shaft runs in common bearings.

The fluid enters the pump axially via a suction nozzle (6) and is accelerated outward

in a cylindrical flow by the rotating impeller (7). In the flow passage of the pump

casing the kinetic energy of the fluid is converted into pressure energy. The fluid is

pumped to the discharge nozzle (2), where it leaves the pump. The casing wear ring

(1) prevents any fluid from flowing back from the casing into the inlet. At the rear

side of the impeller, the shaft (4) enters the casing via the discharge cover (3). The

shaft passage through the discharge cover is sealed towards the atmosphere with a

shaft seal (8). The shaft runs in rolling element bearings (9 and 10), which are

supported by a bearing bracket (5) linked with the pump casing and/or discharge

cover.

The pump is sealed by two bi-rotational mechanical seals in tandem arrangement.

A lubricant reservoir in-between the seals ensures cooling and lubrication of the

mechanical seals.

4.7

Scope of supply

Depending on the model, the following items are included in the scope of supply:

Stationary wet installation (installation types S)

▪

Pump set complete with power cables

▪

Claw with sealing material and mounting elements

▪

Lifting rope or chain

▪

Mounting bracket with mounting elements

Design

Function

Sealing

4 Description of the Pump (Set)

18 of 78

Amarex KRT

Содержание Amarex KRT

Страница 77: ......