35

UAB KOMFOVENT we reserve the right to make changes without prior notice

RHP PRO_22-01

TG3 (13–14)

– for connecting control signal (0..10 V) of an external humidifier or dehumidifier, if activated.

TG2 (15–17)

– power supply (24 V AC) and control signal (0..10 V) for a water cooler mixing valve actuator. If a DX unit

is installed (controlled by a modulated signal), DX unit control signal is connected to these terminals and water cooling is

disabled.

TG1 (18–20)

– power supply (24 V AC) and control signal (0..10 V) for a water heater mixing valve actuator. If a combined

water heater/cooler is used, valve actuator will be controlled by a heating or cooling signal (whichever is supplied).

S2 (21–22)

– 230 V AC supply voltage for a cold water circulation pump, which is used with external water cooler coil and

is activated when cooling is needed. Max 1 A.

S1 (23–24)

– 230 V AC supply voltage for a hot water circulation pump, which is used with external water heater coil and

is activated when heating is needed. Max 1 A.

B8/B9 (25–30)

– terminals for air quality and humidity sensors, which are used for the following functions (see “User

Manual”):

• Air quality control (AQC).

• Recirculation control (REC).

• Operation on demand (OOD).

• Humidity control (HUM).

These functions may be controlled via the following type sensors (sensor type may be changed only by an authorised

service representative):

• Carbon dioxide CO

2

(default setting) – range 0..2000 ppm.

• Air quality VOC (

Volatile organic compound

) – range 0..100 %.

• Relative humidity RH – range 0..100 % RH.

• Temperature TMP – range 0..50 °C.

B6/B7 (31–36)

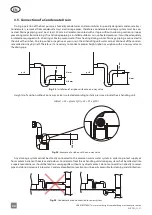

– when a VAV airflow control method is used (see “User Manual”), optional pressure sensors must be

installed and connected in the ducts. Follow the manufacturer’s instructions for installation of VAV pressure sensors. Also,

these terminals are used for DCV airflow control when a separate 0...10 V signal can be used to adjust the ventilation intensity

(see “User Manual”).

FG1 (37–39)

– terminals used to connect air damper actuators. Also terminals are dedicated for smoke by-pass damper

actuator, when optional smoke extraction function is ordered and fans are forced during fire alarm. These terminals may also

be used for connecting 24 V AC power supply actuators with or without a spring return.

Indication (40–42)

– terminals are used when a normally open (NO) contact is necessary for operation status or fault

indication.

Cooling control (43–46)

– digital normally open (NO) outputs for controlling direct expansion (DX) coolers/heaters. The

purpose of outputs differs depending on the type of DX device control ordered or programmed in the control panel

1

:

• Stepping control of start/stop type DX cooling devices – each of the 3 outputs is activated one after the other, when the

power of the previous stage is insufficient, with 5 min. delay.

• Stepping control of start/stop type reversible (cooling/heating) DX devices – DX1 and DX2 outputs are activated one

after the other, when the power of the previous stage is insufficient, with 5 min. delay. DX3 output is used for switching

DX devices between cooling and heating modes.

• If a DX device is controlled by a modulated signal (0..10 V), digital outputs are used for starting a DX unit and changing

operation modes thereof: DX1 – start signal, DX2 – cooling, DX3 – heating. Power control signal for this type of the DX

unit is connected to TG2 terminals.

Water pump/coil alarm (47–48)

– here you can connect signal for indication of water pump faults (if this function is

available on the pump); if the pump fails, the air handling unit is stopped.

All wires to be connected to the main board of the control panel shall be pulled through grommets on top of the unit.

1

If the DX device was not predefined in the controller software, these outputs will be inactive.