4.2 Starting the engine with booster cables

Troubleshooting

4-6

WA70-7 – VENAM02003

4.2

Starting the engine with booster cables

To start the engine with booster cables, proceed as follows:

Precautions for connecting and disconnecting the booster

cables

WARNING

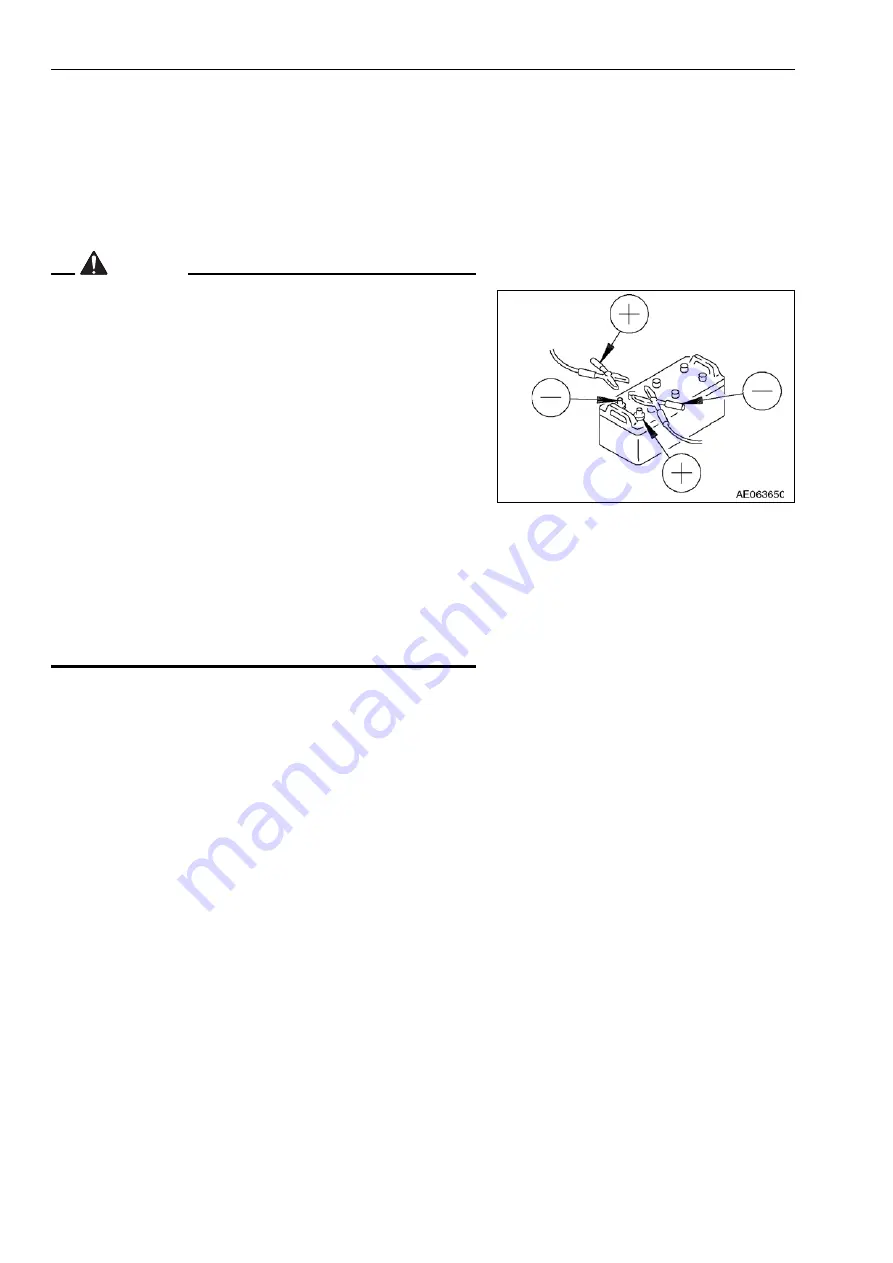

Never touch the positive (+) terminal with the negative (-) ter-

minal when connecting the cables.

Always wear protective goggles when starting the engine

with booster cables.

Ensure that the operational and the defective machine are

not touching each another. This avoids spark formation near

the battery that can ignite the escaping hydrogen gas and

lead to severe injuries or damages.

Ensure that no errors occur during the connection of the

jumper cables. The last connection is made to the engine

block of the defective machine; spark formation occurs here.

Therefore perform the connection at a spot that is as far

away as possible from the battery.

Be careful when disconnecting the cable from the started

machine. Ensure that the cable ends do not come in contact

with one another or the machine to avoid a hydrogen explo-

sion.

NOTICE

The cross section of the jumper cable and the cable termi-

nals have to be selected according to the battery size.

The batteries of the operational and defective machine must

have the same capacity.

Inspect the cables and cable terminals for damages or corro-

sion.

Ensure that the cables and cable terminals are securely fas-

tened.

When connecting a machine to another machine in order to

start it using booster cables, only switch off the battery main

switch once the pilot lamp on the relay box has gone out in

order to prevent damage to the machine's electrical sys-

tems. Remove the key to the battery main switch.

WRONG

Содержание WA70-7

Страница 2: ......

Страница 3: ...Foreword WA70 7 VENAM02003 1 1 1 Foreword...

Страница 23: ...Foreword 1 5 Table of contents WA70 7 VENAM02003 1 21 Blank for technical reason...

Страница 28: ...1 7 Equipment Foreword 1 26 WA70 7 VENAM02003...

Страница 75: ...Operation WA70 7 VENAM02003 3 1 3 Operation...

Страница 114: ...3 2 Descriptions of the individual elements Operation 3 40 WA70 7 VENAM02003 Fuse allocation...

Страница 185: ...Troubleshooting WA70 7 VENAM02003 4 1 4 Troubleshooting...

Страница 203: ...Maintenance WA70 7 VENAM02003 5 1 5 Maintenance...

Страница 276: ...5 8 Maintenance procedure Maintenance every 2000 service hours Maintenance 5 74 WA70 7 VENAM02003...

Страница 277: ...Technical data WA70 7 VENAM02003 6 1 6 Technical data...

Страница 283: ...Special equipment attachments WA70 7 VENAM02003 7 1 7 Special equipment attachments...

Страница 291: ...Index WA70 7 VENAM02003 8 1 8 Index...

Страница 296: ...8 1 Index Index 8 6 WA70 7 VENAM02003...

Страница 297: ...Notes WA70 7 VENAM02003 9 1 9 Notes...

Страница 298: ...Notes 9 2 WA70 7 VENAM02003...

Страница 299: ...Notes WA70 7 VENAM02003 9 3...

Страница 300: ...Notes 9 4 WA70 7 VENAM02003...

Страница 301: ...Notes WA70 7 VENAM02003 9 5...

Страница 302: ...Notes 9 6 WA70 7 VENAM02003...