METHOD FOR REPLACING HYDRAULIC OIL FILTER ELEMENT

k

k

WARNING

• Immediately after the engine is stopped, its parts and oil are still very hot and may cause burn in-

jury. Wait for the temperature to go down, and then start the work.

• When removing the oil filler cap, the oil may spout out. Turn it slowly to release the internal pres-

sure, then remove it carefully.

1.

Lower the bucket to the ground with its bottom level, apply

the parking brake, then stop the engine.

2.

Loosen the bolts and remove cover (1).

3.

Remove mounting bolts (3) (6 pieces) of filter cover (2) on

the top of the tank, then remove the cover.

The cover may be jumped out by spring (4).

While pressing down the cover, remove the bolts.

4.

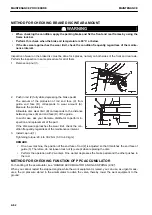

Remove spring (4) and bypass valve (5), then pull out ele-

ment (6).

5.

Check inside of the tank for foreign material, then clean it.

6.

Install new element (6), then set bypass valve (5), spring

(4), and cover (2) to the tank.

If the O-ring of the cover is damaged or deteriorated, re-

place it.

7.

While pressing down the cover, tighten the mounting bolts

evenly.

8.

Check the hydraulic oil level oil level.

Check that the hydraulic oil is at the specified level. For

details, see “METHOD FOR CHECKING OIL LEVEL IN

HYDRAULIC TANK, ADDING OIL (4-42)”.

9.

Run the engine at low idle, and extend and retract each of

the steering, bucket, and boom cylinders 4 to 5 times, tak-

ing care not to move them to the stroke end (stop them approximately 100 mm before the stroke end).

NOTICE

If the engine is run at high speed immediately after startup or a cylinder is pushed up to its stroke

end, air taken inside the cylinder may cause damage to the piston packing.

MAINTENANCE PROCEDURE

MAINTENANCE

4-58

Содержание WA480-8

Страница 2: ......

Страница 19: ...Distributor name Address Phone Fax Service personnel FOREWORD PRODUCT INFORMATION 1 17...

Страница 29: ...LOCATION OF SAFETY LABELS SAFETY SAFETY LABELS 2 3...

Страница 69: ...OPERATION Please read and make sure that you understand the SAFETY section before reading this section 3 1...

Страница 76: ...Outside of cab 1 Slow blow fuse 2 Dust indicator 3 Articulation lock pin 4 Toolbox GENERAL VIEW OPERATION 3 8...

Страница 159: ...SWITCHES 1 ECSS switch 2 Front working lamp switch OPERATION EXPLANATION OF COMPONENTS 3 91...

Страница 302: ...Securing position Fixing angle A 61 B 53 C 33 D 38 TRANSPORTATION OPERATION 3 234...

Страница 324: ......

Страница 325: ...MAINTENANCE Please read and make sure that you understand the SAFETY section before reading this section 4 1...

Страница 397: ...Viewed from the rear side of the machine MAINTENANCE MAINTENANCE PROCEDURE 4 73...

Страница 402: ......

Страница 403: ...SPECIFICATIONS 5 1...

Страница 405: ...1 Value when bucket dump angle is 45 B I A G E H F D C 9 J W0 1 4 5 6 SPECIFICATIONS SPECIFICATIONS 5 3...

Страница 406: ......

Страница 422: ......

Страница 423: ...REPLACEMENT PARTS 7 1...

Страница 439: ......

Страница 440: ...WA480 8 WHEEL LOADER Form No VENAM51500 2018 KOMATSU All Rights Reserved Printed in Europe 07 2018...