8.

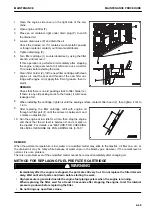

Turn fuel feed pump switch (2) under the fuel prefilter car-

tridge to ON position.

Lamp (3) flashes and the fuel feed pump operates.

9.

After the specified time (approximately 7 minutes), lamp

(3) goes out automatically and the fuel feed pump stops.

When lamp (3) goes out, air bleeding is completed.

10. Start the engine.

If the engine does not start, all air may not be bled. In this

case, start the engine according to the following proce-

dure.

1) Set fuel feed pump switch (2) to ON position.

2) Start the engine while the fuel feed pump is in opera-

tion.

Keep away from the engine while it is being started

and running.

3) After the engine starts, run it for approximately 5 mi-

nutes to bleed all air from the fuel circuit.

4) After approximately 5 minutes, stop the engine. Then,

start the engine as usual.

11. After replacing the filter cartridge, start the engine and check that there is no leakage of fuel from the filter

seal surface.

If there is any leakage of fuel, check the tightening condition of the filter cartridge.

If there is still leakage of fuel, follow steps 2 and 3 to remove the filter cartridge, then check the packing

surface for damage or foreign material. If any problem is found, replace the cartridge with a new one, then

repeat steps 4 to 10 to install the filter cartridge.

METHOD FOR CHANGING OIL IN TRANSMISSION CASE AND CLEANING

TRANSMISSION CASE STRAINER

k

k

WARNING

• Immediately after the engine is stopped, its parts and oil are still very hot and may cause burn in-

jury. Wait for the temperature to go down, and then start the work.

• When removing the oil filler cap, the oil may spout out. Turn it slowly to release the internal pres-

sure, then remove it carefully.

Refill capacity: 65 ℓ

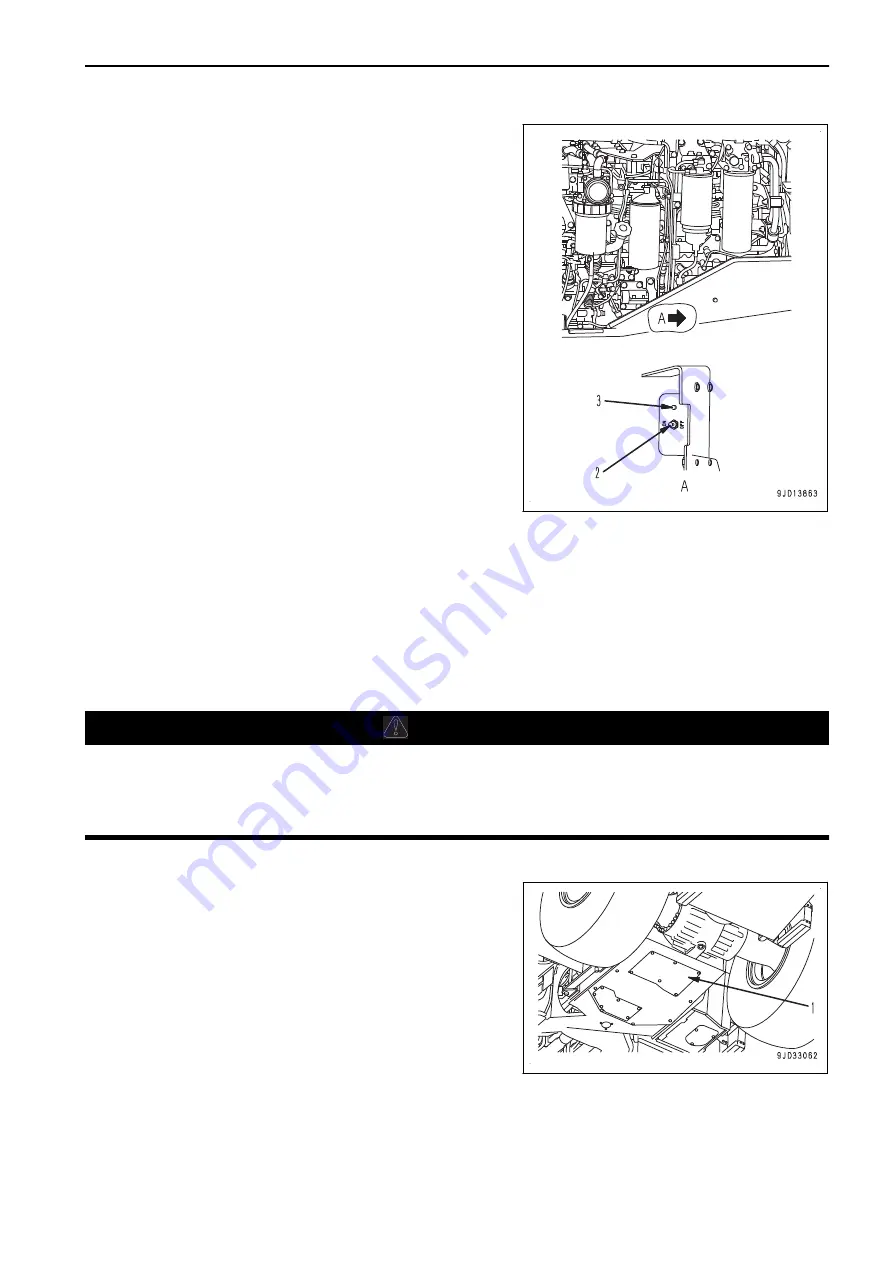

1.

Remove inspection window (1) of the undercover.

MAINTENANCE

MAINTENANCE PROCEDURE

4-53

Содержание WA480-8

Страница 2: ......

Страница 19: ...Distributor name Address Phone Fax Service personnel FOREWORD PRODUCT INFORMATION 1 17...

Страница 29: ...LOCATION OF SAFETY LABELS SAFETY SAFETY LABELS 2 3...

Страница 69: ...OPERATION Please read and make sure that you understand the SAFETY section before reading this section 3 1...

Страница 76: ...Outside of cab 1 Slow blow fuse 2 Dust indicator 3 Articulation lock pin 4 Toolbox GENERAL VIEW OPERATION 3 8...

Страница 159: ...SWITCHES 1 ECSS switch 2 Front working lamp switch OPERATION EXPLANATION OF COMPONENTS 3 91...

Страница 302: ...Securing position Fixing angle A 61 B 53 C 33 D 38 TRANSPORTATION OPERATION 3 234...

Страница 324: ......

Страница 325: ...MAINTENANCE Please read and make sure that you understand the SAFETY section before reading this section 4 1...

Страница 397: ...Viewed from the rear side of the machine MAINTENANCE MAINTENANCE PROCEDURE 4 73...

Страница 402: ......

Страница 403: ...SPECIFICATIONS 5 1...

Страница 405: ...1 Value when bucket dump angle is 45 B I A G E H F D C 9 J W0 1 4 5 6 SPECIFICATIONS SPECIFICATIONS 5 3...

Страница 406: ......

Страница 422: ......

Страница 423: ...REPLACEMENT PARTS 7 1...

Страница 439: ......

Страница 440: ...WA480 8 WHEEL LOADER Form No VENAM51500 2018 KOMATSU All Rights Reserved Printed in Europe 07 2018...