Check method

with engine

running at idle

(1) When

checking the

oil level after

leaving the en-

gine running at

idle (when the

entire trans-

mission is in

heat balance

like immediate-

ly after the ac-

tual operation)

User who op-

erates the ma-

chine continu-

ously (check

during lunch

time or check

at replace-

ment)

(1) Leave the

engine running

at idle for 15

minutes or

more and (2)

check the level

when the indi-

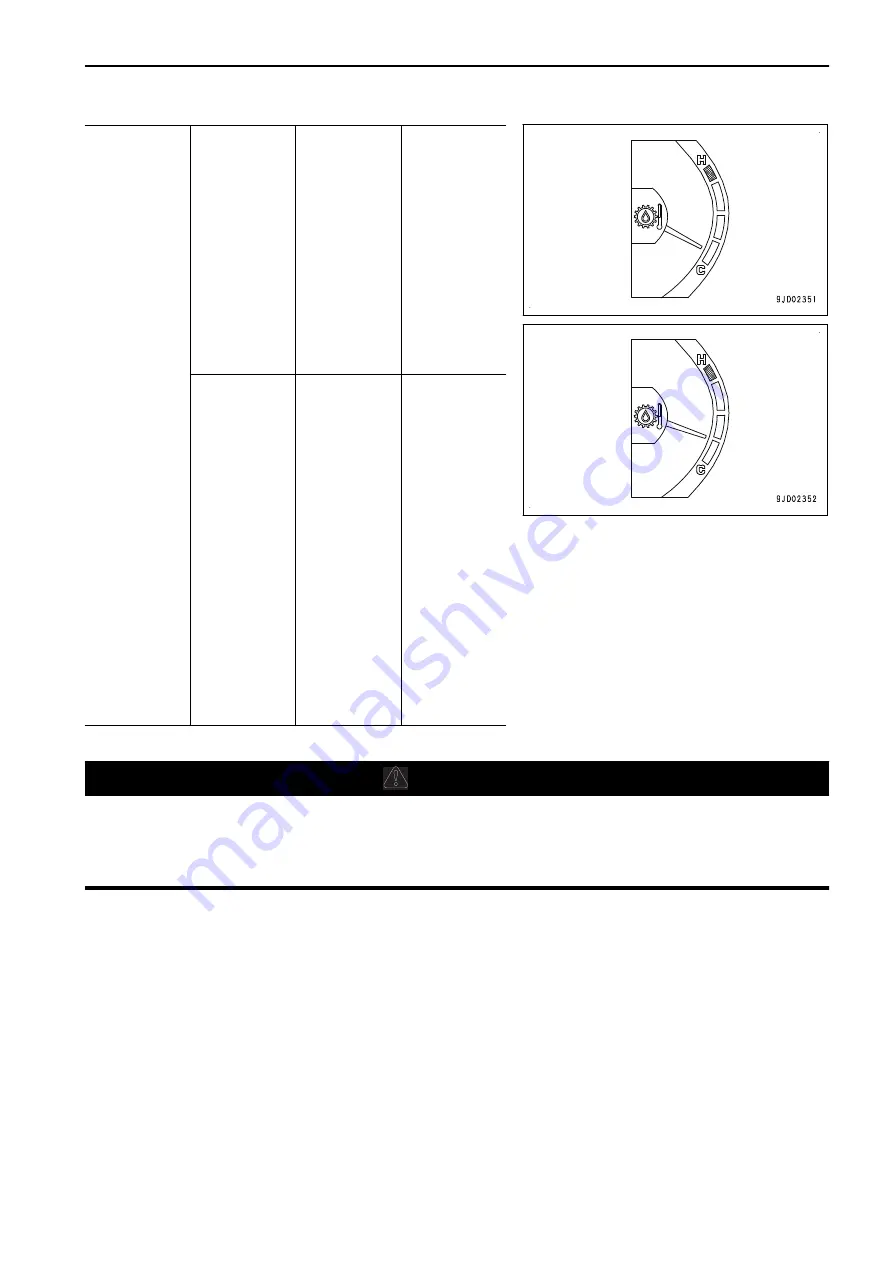

cation of the

torque convert-

er oil tempera-

ture gauge is

at the middle

point of the

lowest scale.

(2) When

checking after

the tempera-

ture is in-

creased at stall

When shipped

from plant, etc.

(1) While the

indication of

the torque con-

verter oil tem-

perature

gauge is at the

middle point

between the

lowest and the

second lowest

scales due to

temperature

increase in the

stall condition,

(2) Run the en-

gine at idle for

approximately

5 minutes and

check the oil

level.

METHOD FOR CHECKING OIL LEVEL IN AXLE CASE AND ADDING OIL

k

k

WARNING

• When checking the oil level, apply the parking brake and fix the front and rear frames using the

frame lock bar.

• Immediately after the engine is stopped, parts and oil are still very hot. Wait for the temperature to

go down, and then start the work.

If ooze of oil is recognized on the axle case, perform the checks.

Place the machine on a level ground before starting the check.

(If the machine is inclined in the right or left, the oil level cannot be checked correctly.)

A: Front, B: Rear

MAINTENANCE

MAINTENANCE PROCEDURE

4-25

Содержание WA480-8

Страница 2: ......

Страница 19: ...Distributor name Address Phone Fax Service personnel FOREWORD PRODUCT INFORMATION 1 17...

Страница 29: ...LOCATION OF SAFETY LABELS SAFETY SAFETY LABELS 2 3...

Страница 69: ...OPERATION Please read and make sure that you understand the SAFETY section before reading this section 3 1...

Страница 76: ...Outside of cab 1 Slow blow fuse 2 Dust indicator 3 Articulation lock pin 4 Toolbox GENERAL VIEW OPERATION 3 8...

Страница 159: ...SWITCHES 1 ECSS switch 2 Front working lamp switch OPERATION EXPLANATION OF COMPONENTS 3 91...

Страница 302: ...Securing position Fixing angle A 61 B 53 C 33 D 38 TRANSPORTATION OPERATION 3 234...

Страница 324: ......

Страница 325: ...MAINTENANCE Please read and make sure that you understand the SAFETY section before reading this section 4 1...

Страница 397: ...Viewed from the rear side of the machine MAINTENANCE MAINTENANCE PROCEDURE 4 73...

Страница 402: ......

Страница 403: ...SPECIFICATIONS 5 1...

Страница 405: ...1 Value when bucket dump angle is 45 B I A G E H F D C 9 J W0 1 4 5 6 SPECIFICATIONS SPECIFICATIONS 5 3...

Страница 406: ......

Страница 422: ......

Страница 423: ...REPLACEMENT PARTS 7 1...

Страница 439: ......

Страница 440: ...WA480 8 WHEEL LOADER Form No VENAM51500 2018 KOMATSU All Rights Reserved Printed in Europe 07 2018...