4.

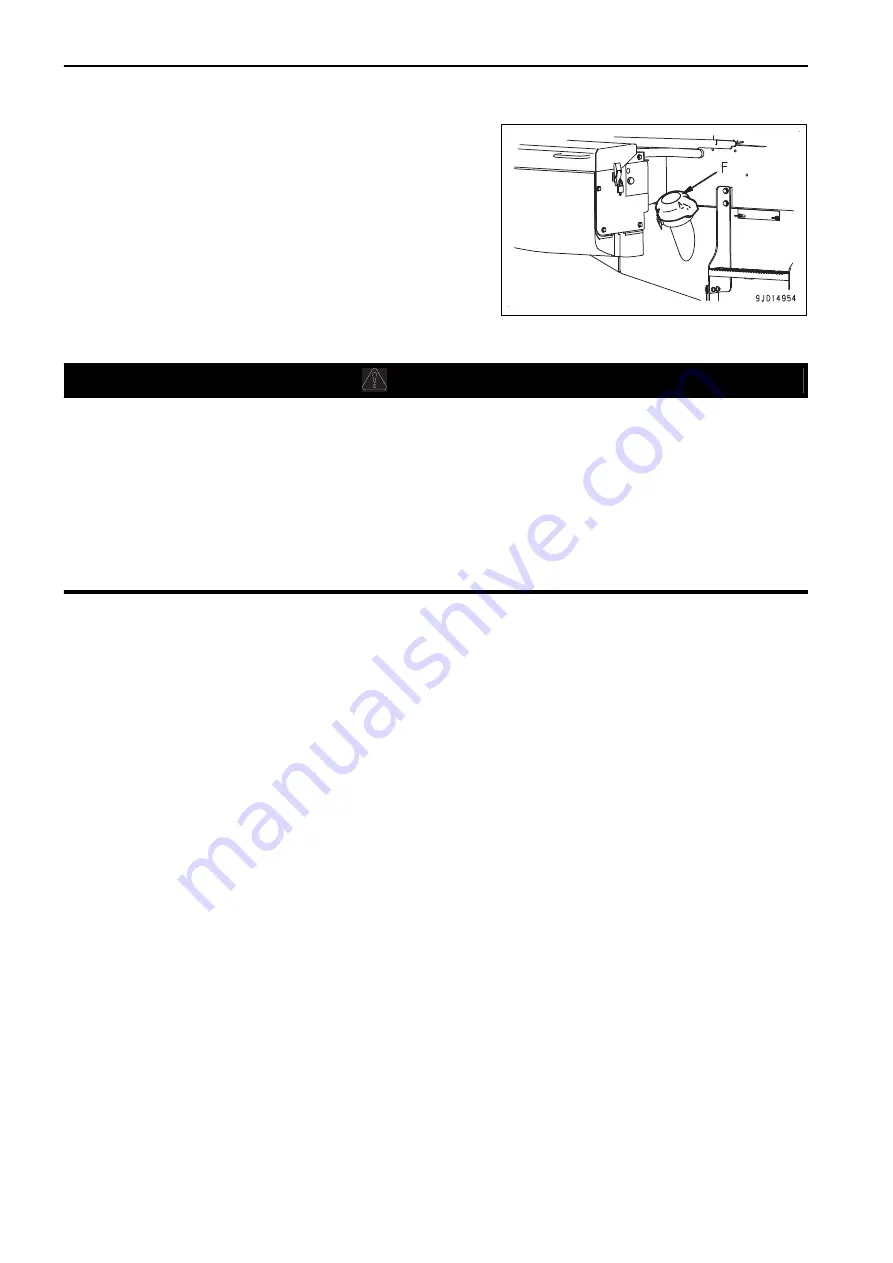

After operations are completed, fill the fuel tank fully by

adding fuel through oil filler port (F) on the rear right side of

the machine.

Once the tank is filled up, do not try to supply additional

fuel.

For the cap opening and closing procedure, see “METH-

OD FOR OPENING AND CLOSING CAP WITH LOCK

(3-218)”.

5.

After adding, tighten the fuel filler cap securely.

Fuel tank capacity: 380 ℓ

METHOD FOR CHECKING DEF LEVEL AND ADDING DEF

k

k

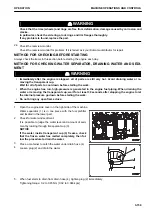

WARNING

• Do not put any fluid other than DEF into DEF tank.

• When opening the cap of DEF tank of the machine, the ammonia vapor may escape. Keep your face

away from the filler port during opening or refilling.

• Foreign materials entered in DEF system or urea deposit by urea separation may disturb the opera-

tion of the system. Before removing the filler cap, wipe off the dirt from around the filler port. Before

inserting the filler nozzle into the filler port, wipe off dirt from it.

• If DEF is spilled, immediately wash and clean the area with water. If spilled DEF is left unattended

and the area is not washed and cleaned, it can cause corrosion to the contaminated area and emit

toxic gas.

NOTICE

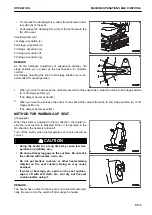

• Do not add DEF more than the line F of sight gauge (7). DEF may leak through the breather. When

DEF may freeze in cold weather, do not add it more than the line (11) of sight gauge (7).

Be careful of the DEF line to be added when performing operations on a slope or traveling on a

rough ground. When the remaining DEF level is low, it may become the warning level if DEF pump

sucks air or if DEF level suddenly drops.

• If DEF is stored in another container, foreign material may be mixed in it and toxic gas or corrosive

substance may be produced by chemical reactions. When adding DEF, do not transfer it to another

container.

• If you use a funnel to add DEF, the strainer will be broken. Do not use a funnel.

• When using a portable refill container, use it up each time. If any of it is left, completely seal it up.

Remove the foreign material, if there is any.

• Do not wash the supply nozzle in city water. Minerals may clog the devices.

• Do not dilute DEF with water.

• If you add fluid other than DEF (diesel fuel, low concentration DEF, etc.) by mistake, the caution

lamp lights up and the alarm buzzer sounds to warn the abnormality. In this case, ask your Komatsu

distributor for draining of the wrong fluid and inspection. DEF injector and/or DEF pump may need

to be replaced.

MACHINE OPERATIONS AND CONTROLS

OPERATION

3-164

Содержание WA480-8

Страница 2: ......

Страница 19: ...Distributor name Address Phone Fax Service personnel FOREWORD PRODUCT INFORMATION 1 17...

Страница 29: ...LOCATION OF SAFETY LABELS SAFETY SAFETY LABELS 2 3...

Страница 69: ...OPERATION Please read and make sure that you understand the SAFETY section before reading this section 3 1...

Страница 76: ...Outside of cab 1 Slow blow fuse 2 Dust indicator 3 Articulation lock pin 4 Toolbox GENERAL VIEW OPERATION 3 8...

Страница 159: ...SWITCHES 1 ECSS switch 2 Front working lamp switch OPERATION EXPLANATION OF COMPONENTS 3 91...

Страница 302: ...Securing position Fixing angle A 61 B 53 C 33 D 38 TRANSPORTATION OPERATION 3 234...

Страница 324: ......

Страница 325: ...MAINTENANCE Please read and make sure that you understand the SAFETY section before reading this section 4 1...

Страница 397: ...Viewed from the rear side of the machine MAINTENANCE MAINTENANCE PROCEDURE 4 73...

Страница 402: ......

Страница 403: ...SPECIFICATIONS 5 1...

Страница 405: ...1 Value when bucket dump angle is 45 B I A G E H F D C 9 J W0 1 4 5 6 SPECIFICATIONS SPECIFICATIONS 5 3...

Страница 406: ......

Страница 422: ......

Страница 423: ...REPLACEMENT PARTS 7 1...

Страница 439: ......

Страница 440: ...WA480 8 WHEEL LOADER Form No VENAM51500 2018 KOMATSU All Rights Reserved Printed in Europe 07 2018...